Fully Automatic Filter Press with Boom Door

- Payment Type:

- T/T, D/P

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen,China |

|---|---|

| Payment Type: | T/T,D/P |

| Incoterm: | FOB |

| Certificate: | CE,RoHS |

| HS Code: | 8421291090 |

| Transportation: | Ocean |

| Port: | Shenzhen |

Product Description

Product Description

Fully Automatic Filter Press with Boom Door

Auto Feeding High Efficiency Filter press is suitable for materials with large viscosity and difficult to automatically fall off. the filter cloth vibraant system developed by our company can change the inclination angle of the filter colth during operation ,and it can be inverted V-shaped , and at the same time, the flex of spring on the filter cloth causes the filter cake to fall off automatically , Flex rod is made of FRPP,which is lightweiht and anti-corrosion, easy operation and maintenance.

| Model | Filter Area m2 | Filter Plates (layer) | Filter chambers volume (m³) | Dimension (L*W*H )mm | Hydraulic Power (kw) | Plate size(mm) |

| XAMZ200/1500-35U | 200 | 49 | 3030 | 7050*2260*1925 | 7.5 | 1500*1500 |

| XAMZ250/1500-35U | 250 | 61 | 3739 | 7890*2260*1925 | ||

| XAMZ300/1500-35U | 300 | 74 | 4431 | 8800*2260*1950 | ||

| XAMZ400/1500-35U | 400 | 99 | 6007 | 10670*2260*1950 | ||

| XAMZ500/1500-35U | 500 | 123 | 7478 | 12350*2260*1950 | ||

| XAMZ500/2000-40U | 500 | 69 | 10000 | 9720*2800*2425 | 11 | 2000*2000 |

| XAMZ600/2000-40U | 600 | 83 | 12000 | 10840*2800*2425 | ||

| XAMZ700/2000-40U | 700 | 97 | 14000 | 12160*2800*2425 | ||

| XAMZ900/2000-40U | 900 | 125 | 18000 | 14000*2800*2425 | ||

| XAMZ1000/2000-40U | 1000 | 139 | 20000 | 15110*2800*2425 |

|

|

unit | GPY-40 | GPY-60 |

| speed of agitator | r/min | 73 | |

| Mixing motor Work rate | Kw | 2.2 | |

| Feed size |

|

Less than 0.063 mm fraction content is not more than 35-40% | |

| capacity | t/h | 8-12 | 12-18 |

| Product water | % | 22-24 | |

Company Profile

Shenzhen HONGFA ENVIRONMENTAL PROTECTION EQUIPMENT CO.,Ltd has become one of the world's leading manufacturers of high-quality filter presses in the field of solid-liquid separation

It is a professional one-stop company covers develop,design,produce,sale and after-service,the company has a professional R&D team, and draws on the advance technology of the world on the products and innovates constantly Company also has environment protection equipment manufacturing factory and filter press accessories manufacturing factory.

The company specializes in filter equipment and related accessories,such as the series of plate and frame filter press,chamber filter press,membrane filter press ,cast iron filter press, stainless steel filter press,filter plate,filter cloth,water faucet and other accessories,filter press be widely used in petroleum,chemical, food ,pharmaceutical,paper making,coal washing , ceramics,mine and other sewage treatment industries

The filter press has 320/450/630/800/1000/1250/1500/2000 type the filtration area ranges from 0.5m2 to 2000m2,Compaction types include jack compaction, mechanical compacting,hydraulic compacting,etc. The material of filter plate contain FRPP,TPE, glass fiber polypropylene,cast iron,stainless steel etc.

Company adhering to the tenet of quality first ,credit important specification complete and id committed to developing to the largest scale and best quality manufacturing company

Factory Shop

Structure and operating principle

Filter press consist of frame, filter plate, pressing system(manual, mechanical or hydraulic ) and electric control cabinet.

Frame consists of base, push plate and girder and supports the pressing device and filter plates.

Filter plates are installed on girder between tail plate and push plate, with filter cloth sandwiched in them.

In operation, the pressing device(cylinder piston rod or screw ) drives the push plate to press the filter plates and filter cloth between push plate and tail plate. Filter chambers are formed between pressed filter plates and material get in to The filter chambers through the feeding port in tail plate. Solid particles are trapped in filter chambers form into cakes, while liquid is discharged out of the tail Plate. In similar manner, to drying the press cakes, compressed air can be introduced through the washing port.

Plate and frame type filter-Press is the same as recessed plate filter press in structure, except the filtering part that consists of one plate, one frame and filter cloth, with filter chamber between plate and frame.

Liquid stream of filter press can be divided into exeternal stream and internal stream. Exeternal streamrefers to that the filtrate is discharged directly from outlet port of filter plate; Internal stream refers to that the filtrate from various filter plate is collected before being discharged out of the filtrate port.

Product Show

Our Project on Sewage treatment cases

Advantages of Shenzhen HONGFA Filter Press:

1. Low filter cake moisture;

2. Unmanned operation and cost saving;

3. Resist high temperature and corrosion;

4. Good sealing effect can perfectly avoid leskage;

5. Energy saving high performance chamber filter press with long working life

----F A Q

1. What's the payment details?

Deposit before production, and balance before shipment.

2. What's the delivery time?

For common order, about 20 days only.

3. What about the warranty for the machine?

Free warranty for one year

4. Do you provide OEM Service?

Yes. OEM & ODM Service is ok for us.

5. What's the MOQ?

1 SET

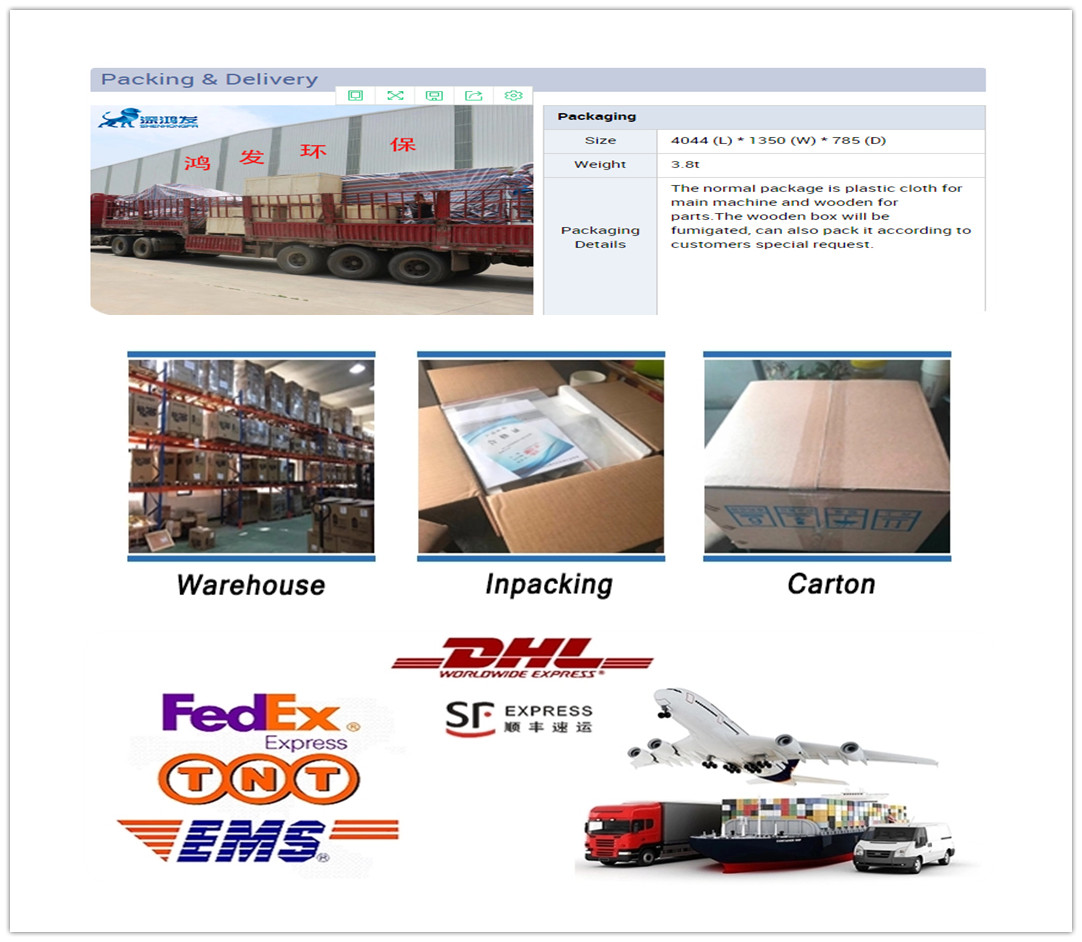

6. How about the package?

suitable for sea freight as per your request.

For more information , pls just feel free to contact, we could provide different kinds of filter press with high quality and low prices, coz we are the factory !

Related Keywords

Related Keywords