Filter press use for used car oil

-

$580.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Land, Ocean

- Port:

- SHENZHEN, HONGKONG

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | china |

|---|---|

| Productivity: | 1000pcs/week |

| Supply Ability: | 1000PCS/WEEK |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

| Incoterm: | CFR,FOB,CIF,EXW,FAS |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 84212910 |

| Transportation: | Land,Ocean |

| Port: | SHENZHEN,HONGKONG |

Product Description

Product Description

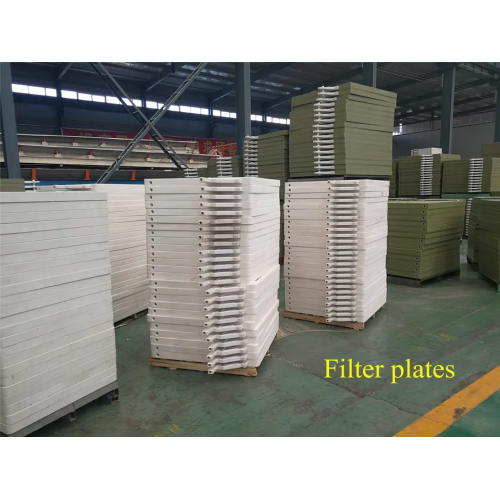

1. Plate and Frame Design: The filter press consists of a series of plates and frames that are arranged in a vertical position. The plates are covered with filter cloths that capture the solids while allowing the liquid to pass through.

2. Automatic Operation: Many modern filter presses are equipped with automatic controls that regulate the pressure, flow rate, and cycle time. This ensures consistent performance and reduces the need for manual intervention.

3. High Capacity: The filter press is capable of processing large volumes of slurry and can handle a wide range of materials, including industrial wastewater, mining tailings, and food products.

4. Efficient Filtration: The filter press is designed to provide efficient solid-liquid separation, with high removal rates of suspended solids and other contaminants.

5. Versatile Applications: The filter press is used in a variety of industries, including mining, chemical processing, food and beverage, and wastewater treatment.

6. Low Maintenance: The filter press requires minimal maintenance and is easy to operate, with few moving parts that can wear out or break down.

7. Customizable Design: The filter press can be customized to meet specific requirements, with options for plate size, material, and configuration.

8. Environmentally Friendly: The filter press is an environmentally friendly option for solid-liquid separation, as it generates minimal waste and can be used to recover valuable materials from the slurry.

2. Automatic Operation: Many modern filter presses are equipped with automatic controls that regulate the pressure, flow rate, and cycle time. This ensures consistent performance and reduces the need for manual intervention.

3. High Capacity: The filter press is capable of processing large volumes of slurry and can handle a wide range of materials, including industrial wastewater, mining tailings, and food products.

4. Efficient Filtration: The filter press is designed to provide efficient solid-liquid separation, with high removal rates of suspended solids and other contaminants.

5. Versatile Applications: The filter press is used in a variety of industries, including mining, chemical processing, food and beverage, and wastewater treatment.

6. Low Maintenance: The filter press requires minimal maintenance and is easy to operate, with few moving parts that can wear out or break down.

7. Customizable Design: The filter press can be customized to meet specific requirements, with options for plate size, material, and configuration.

8. Environmentally Friendly: The filter press is an environmentally friendly option for solid-liquid separation, as it generates minimal waste and can be used to recover valuable materials from the slurry.

Related Keywords

Related Keywords