Automatic Chamber Filter Press with Cloth Washing System

-

$4000.00≥2000 Set/Sets

- Min. Order:

- 2000 Set/Sets

- Min. Order:

- 2000 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Tianjin, Shenzhen, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 3000sets/year |

| Supply Ability: | 3000sets/year |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,FAS,FCA |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Tianjin,Shenzhen,Shanghai |

Sludge Dewatering Filter Press

As we all know, the filter press is a kind of auxiliary device for separating solid and liquid in the process of sewage treatment, so as to facilitate the better treatment of sewage. It has been widely used in the field of environmental protection. When the filter press is in use, the sewage is first transported to the storage tank, and then the switch of the hydraulic station is opened, the first hydraulic cylinder is moved to the elongation knob, so that the hydraulic rod in the first hydraulic cylinder is extended, and the pressing plate is pushed to press the filter plate, and the pressure pump is opened to press the sewage into the filter plate through the feed port. After the action is completed, The particles and other impurities in the sewage are intercepted in the filter chamber between the filter plates through the filter cloth, and the filtrate flows out from the outlet to the waste liquid tank. When the filtrate no longer flows out, the first hydraulic cylinder is moved to the contraction knob, the hydraulic rod in the first hydraulic cylinder shrinks, driving the filter plate to pull open successively, and then the filter cake can be taken out.The emergence of the filter press with automatic washing of the press cloth successfully solved the manual cleaning of the press cloth and the process of frequent replacement of the press cloth, greatly saving the labor cost, but also extended the service life of the machine.

Types of Filter Press according to:

> Closing mode: manual, gear drive, hydraulic;

> Filtrate flow: open flow, close flow, cake washing, non-cake washing, center feeding, corner feeding,etc..

> Filter plate structure: recessed plate, plate &frame, diaphragm squeeze (membrane) plate;

> Filter plate material: PP, rubber, cast iron, stainless steel;

> Filter Plate size: 320, 450, 630, 800,1000, 1250, 1500, 2000

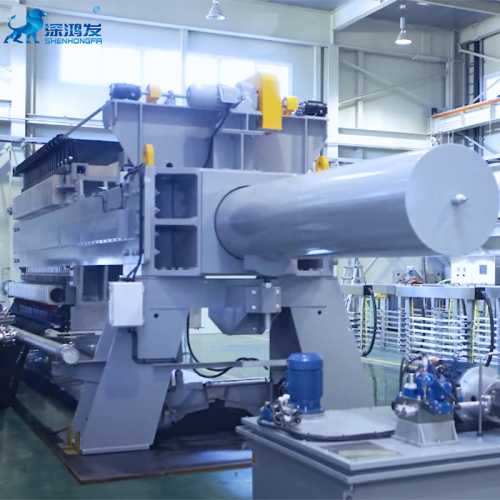

WORK SHOP

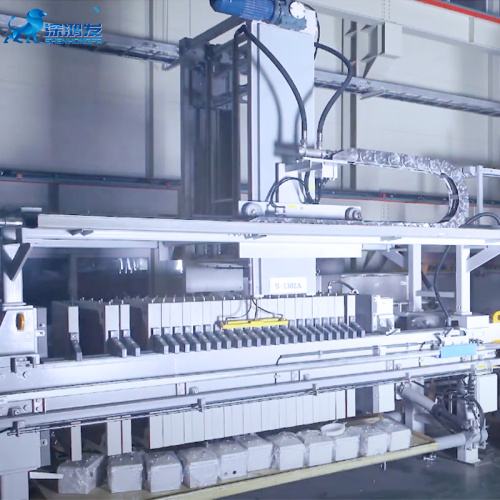

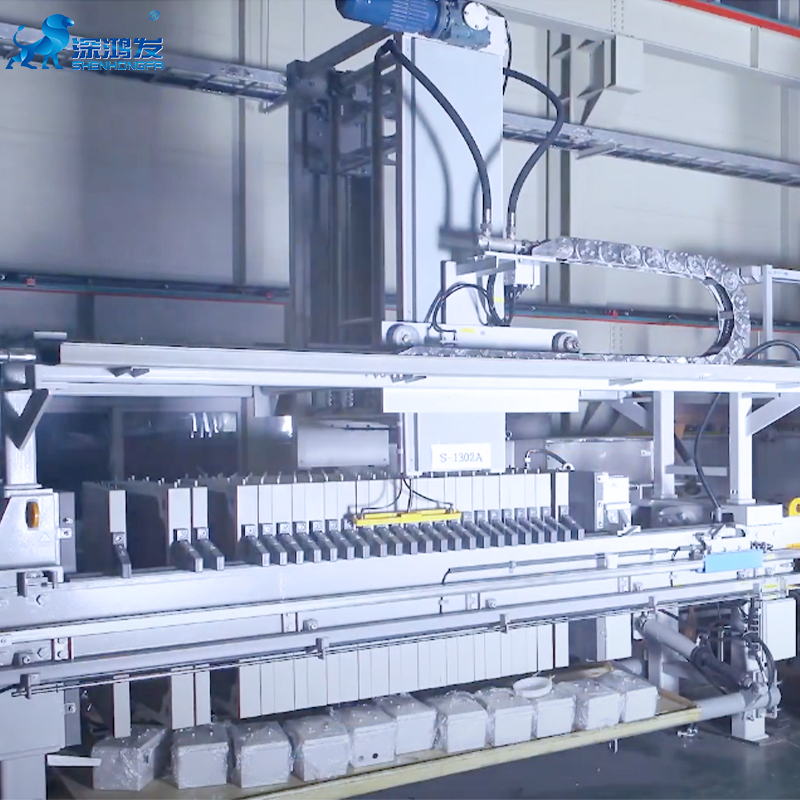

PRODUCT SHOW

1) The plate-frame sludge filter press is an intermittent solid-liquid separation device.

2) It consists of a filter plate and a filter frame arranged to form a filter room. Under the pressure of the feed pump, the feed liquid is sent to each filter room through filtration.

3) Medium, separating solids from liquids. It has the advantages of good separation effect, wide application scope, simple operation, and low investment.

4) Especially for the separation of viscous material, it has unparalleled superiority

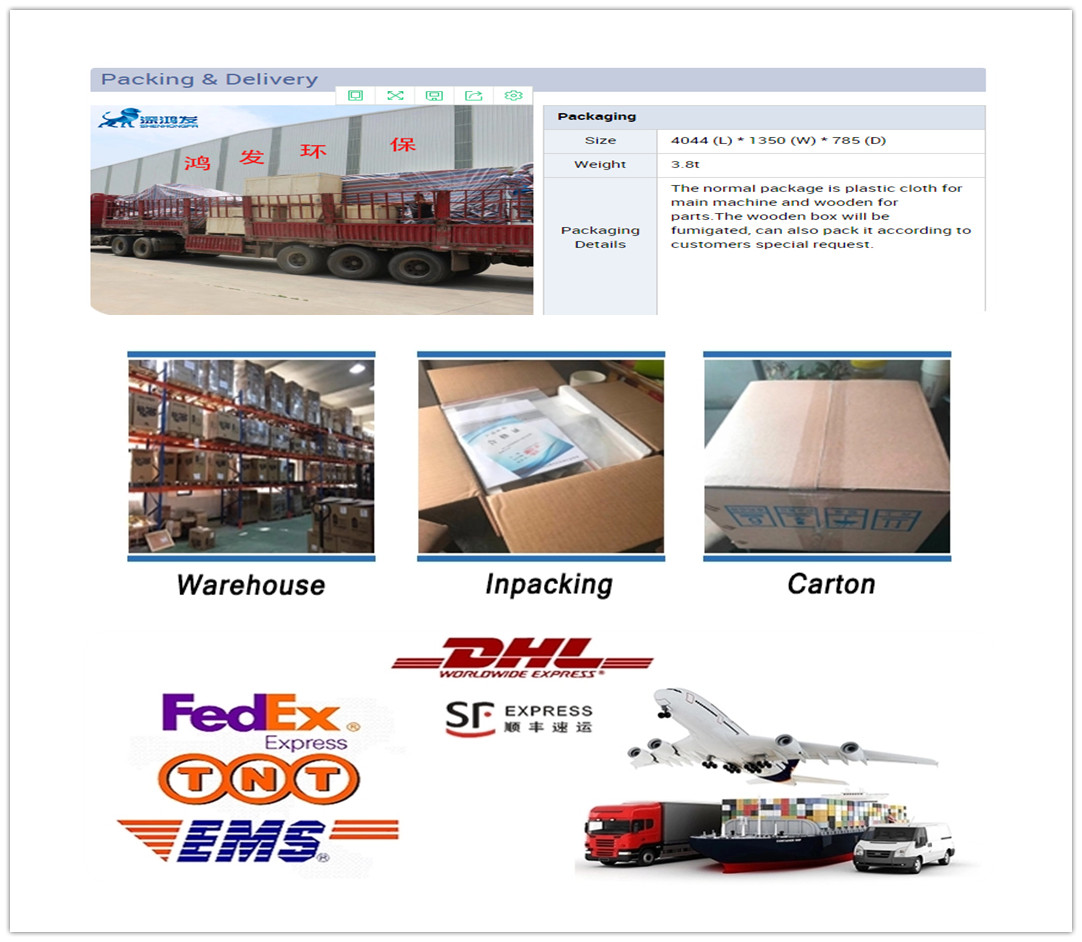

PACKING AND DELIVERY

Our Engineering Project

Advantages of Shenzhen HONGFA Filter Press:

1. Low filter cake moisture;

2. Unmanned operation and cost saving;

3. Resist high temperature and corrosion;

4. Good sealing effect can perfectly avoid leskage;

5. Energy saving high performance chamber filter press with long working life

FAQ:

-------1. How to buy your interested products?

You can provide us the water sources, water quality, flow rate and ground area, material requirements about your project (More details, please contact us).

-------2. How to pay?

L/C or T/T are acceptable.Usually, 50% payment in advance, 50% payment before delivery.

-------3. What is the delivery time?

It depends on order quantities. Generally speaking, the delivery time will be within 1 months.

-------4. How to pack the products?

We use standard export package.If you have special package requirements, we will pack as you required, but the fees will be paid by customers.

-------5. How to install after the equipment arriving destination?

We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you.

-------6. How long is the validity?

The validity is 12 months after installation

Related Keywords