Automatic filter cloth washing filter press

-

$9000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- SHENZHEN, TIANJIN, SHANGHAI

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 100sets/month |

| Supply Ability: | 100sets/month |

| Payment Type: | T/T,Paypal,L/C |

| Incoterm: | FOB,CIF,EXW,FAS,FCA |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 84212910.90 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN,TIANJIN,SHANGHAI |

Automatic filter cloth washing filter press

Washing method, when the filter cake needs to be washed, there are open flow one-way washing and two-way washing, dark flow one-way washing and two-way washing.

A. In open-flow one-way washing, the lotion enters the hole from the thrust plate in turn, passes through the filter cloth and then through the filter cake, and flows out from the non-porous filter plate. At this time, the outlet water nozzle of the perforated plate is closed, while the outlet water nozzle of the non-perforated plate is open.

B. Open flow two-way washing means that the lotion enters the holes on both sides above the thrust plate and washes twice successively, that is, the lotion is washed from one side first and then from the other side. The outlet of the lotion is opposite to the inlet. Angular direction, so it is also called two-way cross washing.

C. Undercurrent unidirectional flow washing is that the washing liquid enters the porous plate from the washing liquid inlet hole of the thrust plate in turn, passes through the filter cloth and then passes through the filter cake, and flows out from the non-porous filter plate.

D. Undercurrent two-way washing means that the washing liquid is washed twice successively from the two washing liquid inlet holes on both sides above the stop plate, that is, the washing is washed from one side first, and then from the other side. The outlet of the washing liquid is diagonal direction, so it is also called undercurrent two-way cross washing.

1) The plate-frame sludge filter press is an intermittent solid-liquid separation device.

2) It consists of a filter plate and a filter frame arranged to form a filter room. Under the pressure of the feed pump, the feed liquid is sent to each filter room through filtration.

3) Medium, separating solids from liquids. It has the advantages of good separation effect, wide application scope, simple operation, and low investment.

4) Especially for the separation of viscous material, it has unparalleled superiority

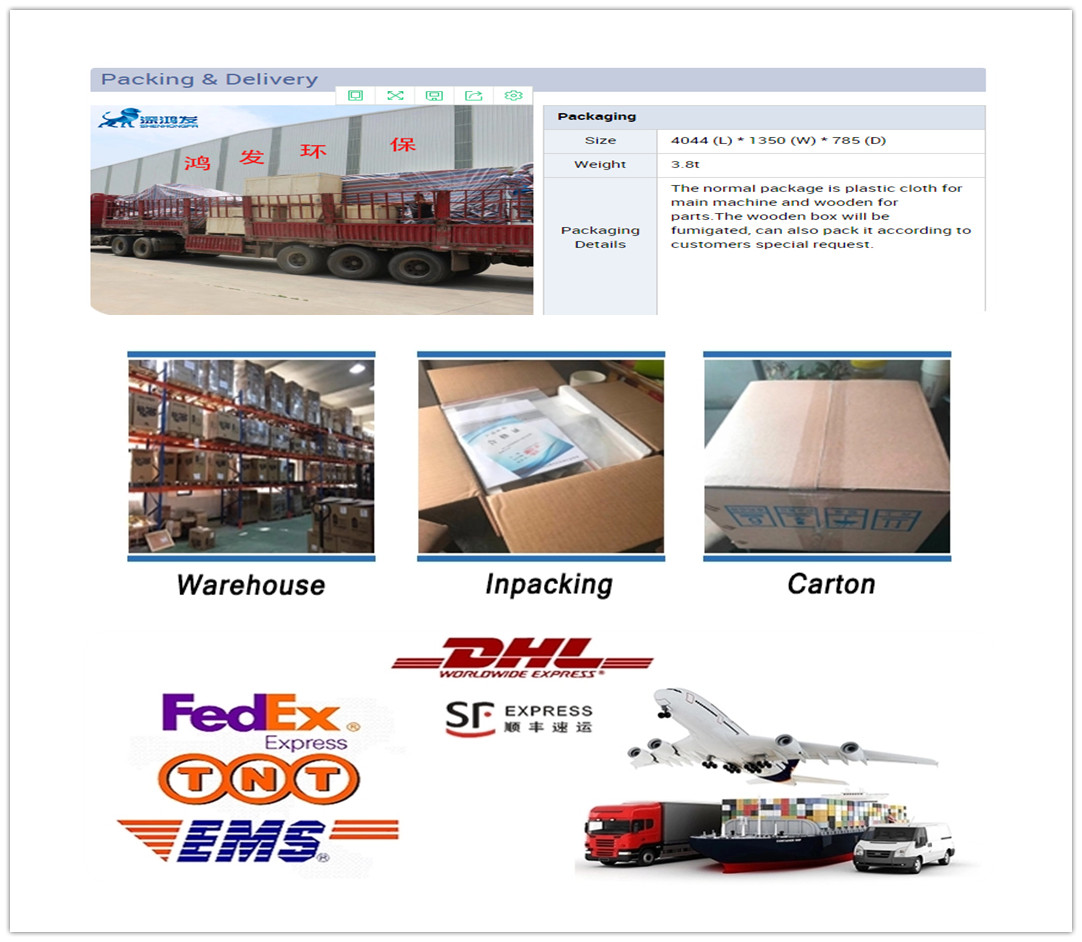

PACKING AND DELIVERY

Our Engineering Project

We are offering full specifications of filter presses for sludge dewatering treatment.

Our filter presses include recessed type, membrane squeezing types, plate & frame types.

Filtration area ranges 1to 1000 sq meters.

Filter plate sizes are from 315 to 2000mm.

The filter presses are in manual, hydraulic automatic types for optional.

If you need any detailed information for our company or products, please feel free to contact us.

Warmly welcome customers from all over the world come to visit our factory and have business discussion with us.

Related Keywords