High Quality Belt Filter Press Machine for Dewatering

-

$4000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Tianjin, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100sets/month |

| Supply Ability: | 100sets/month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS |

| Certificate: | CE,RoHS |

| HS Code: | 8421291090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Tianjin,Shanghai |

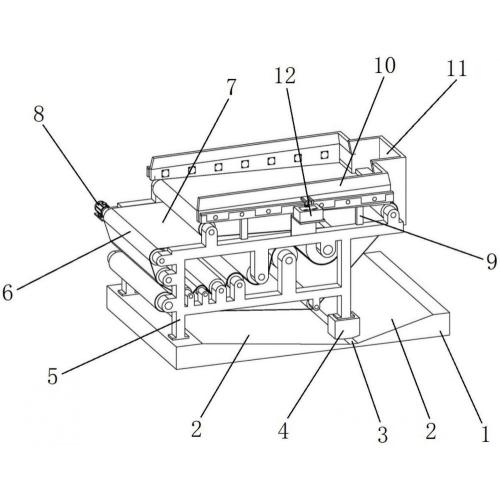

Product introduction:

The belt filter press is a new type of three-network sludge dewatering filter press equipment that our company has absorbed and digested new sludge dewatering technology and improved through repeated research and practice. It has high sludge dehydration rate, mud cake It has the characteristics of high solid content, its main technical indicators have reached the domestic level, and its application range is very wide. Belt press filter adopts different arrangements and combinations to form many different models. It has the advantages of simple structure, dehydration, large processing capacity, low energy consumption, low noise, high degree of automation, continuous operation, easy operation, etc. Its cost and operation cost are more than 30% higher than that of plate and frame filter press, so it has become the first choice for urban sewage treatment. equipment.

Scope of application:

It is widely used in continuous dehydration of industries such as mining, ceramics, chemical industry, metallurgy, starch, fruit juice, manufacturing, fruit juice, electric power, coal, paper making, bean dregs, slag, wine, wood slag, etc.

Process characteristics of belt sludge dewatering machine:

1. The residence time of sludge concentration is short. The residence time of sludge concentration tank generally takes more than ten hours, while the dehydration residence time of belt concentration section is only tens of seconds to 1-2 minutes on average.

2. The belt-type concentration section is designed as an inclined type, which improves the static pressure head of the feeding part and improves the dehydration efficiency.

3. Both the concentration section and the filter press section adopt stepless speed regulation to achieve a good process match.

4. Filter cloth deviation correction device: adopts pneumatic feedback single-side automatic deviation correction.

5. Filter cloth cleaning device: automatic cleaning with nozzle and scrubbing mechanism.

6. Filter cloth tensioning device: Pneumatic tensioning is adopted, so the operation is flexible and the maintenance is simple and convenient.

Flocculation conducts reasonable tempering treatment on the sludge, and uses the principle of gravity dehydration and mechanical dehydration to remove the water in the sludge, so that the sludge forms a filter cake state. The mud cake after gravity dehydration of various industrial sludge can be added to the filter belt, and then it can be dehydrated rapidly in the filter press, and the arrangement of the pressure rollers that are gradually smaller and the angle of the filter belt can be changed to ensure the combination of pressure and shear. , thus greatly improving the solid content of mud cake and dehydration efficiency, and the specially designed electromagnetic deviation adjustment and filter belt tensioning solve some difficulties in the use of equipment.

PACKING AND DELIVERY

Our Engineering Project

Advantages of Shenzhen HONGFA Filter Press:

1. Low filter cake moisture;

2. Unmanned operation and cost saving;

3. Resist high temperature and corrosion;

4. Good sealing effect can perfectly avoid leskage;

5. Energy saving high performance chamber filter press with long working life

Related Keywords