Chamber Filter Press (Chamber Plate Filter Press)

-

$2000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- shenzhen, shanghai, qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | 5000sets/year |

| Supply Ability: | 5000sets/year |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 8421291090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | shenzhen,shanghai,qingdao |

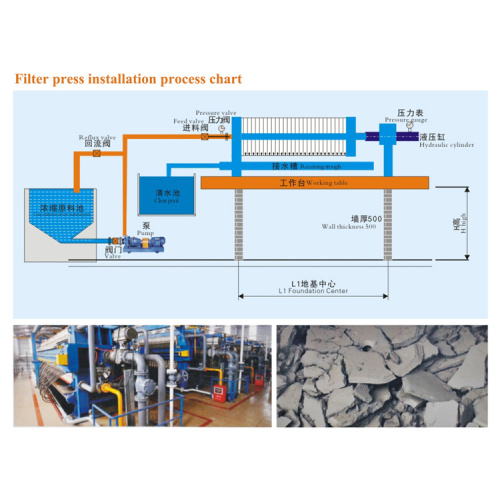

Working principle of high pressure diaphragm filter press

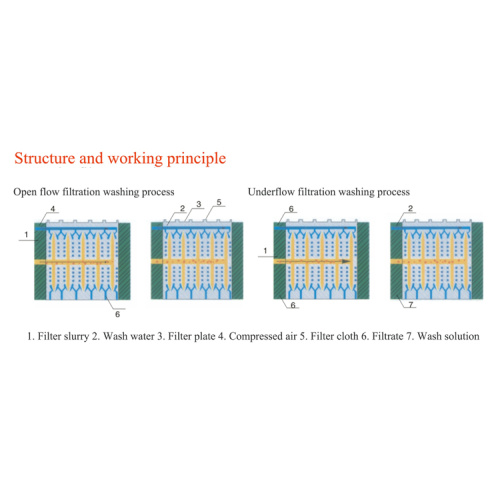

1, the frame is the basis of the whole equipment, it is mainly used to support the filter mechanism, by the thrust plate, the pressing plate, the frame, the cylinder block and the main beam connection. When the equipment is running, the piston rod on the cylinder block pushes the pressing plate, and the diaphragm plate, filter plate and filter cloth located between the pressing plate and the thrust plate are pressed to ensure that the filter slurry with pressure is pressurized and filtered in the filter chamber. 2. The filtration part is composed of a diaphragm filter plate neatly arranged on the main beam, a panel filter plate and a filter cloth sandwiched between them. At the beginning of filtration, the filter pulp is pushed by the feed pump and enters the filter chamber through the feed port of the thrust plate. The filter pulp is separated from the solid by the pressure generated by the feed pump. Due to the function of the filter medium (filter cloth), the solid remains in the filter chamber to form filter cake, and the filtrate is discharged by the discharge valve. 3, the hydraulic part is the main engine to complete the pressing and loosening action of the power device, under the action of the electrical control system, through the cylinder, oil pump and hydraulic components to complete a series of work of the system: when the system is pressed, the filter chamber seal, for filtration; On the contrary, when loosening, it is used for unloading. 4, the unloading mechanism is mainly composed of two reduction motor, drive shaft, sprocket, chain and other components. When the pressing plate is loosened, the motor at the position of the support seat starts, pulls the cylinder seat and the pressing plate through the sprocket and chain, and pulls the filter plate apart. The motor at the position of the thrust plate starts, and drives the partition board to pull apart the second part of the filter plate. The signal transmission in the electric control cabinet makes it reverse, and drives the partition board to pull apart the remaining filter plate. 5. The electrical control part is the control center of the whole system, which is mainly composed of electric control cabinet, circuit breaker, air switch, contactor, intermediate relay, PLC(programmable controller), travel switch, proximity switch and TD200 text display, etc., which can automatically control the whole filter press cycle.

Related Keywords