Automatic Food Oil Hydraulic Chamber Filter Press

-

$3000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

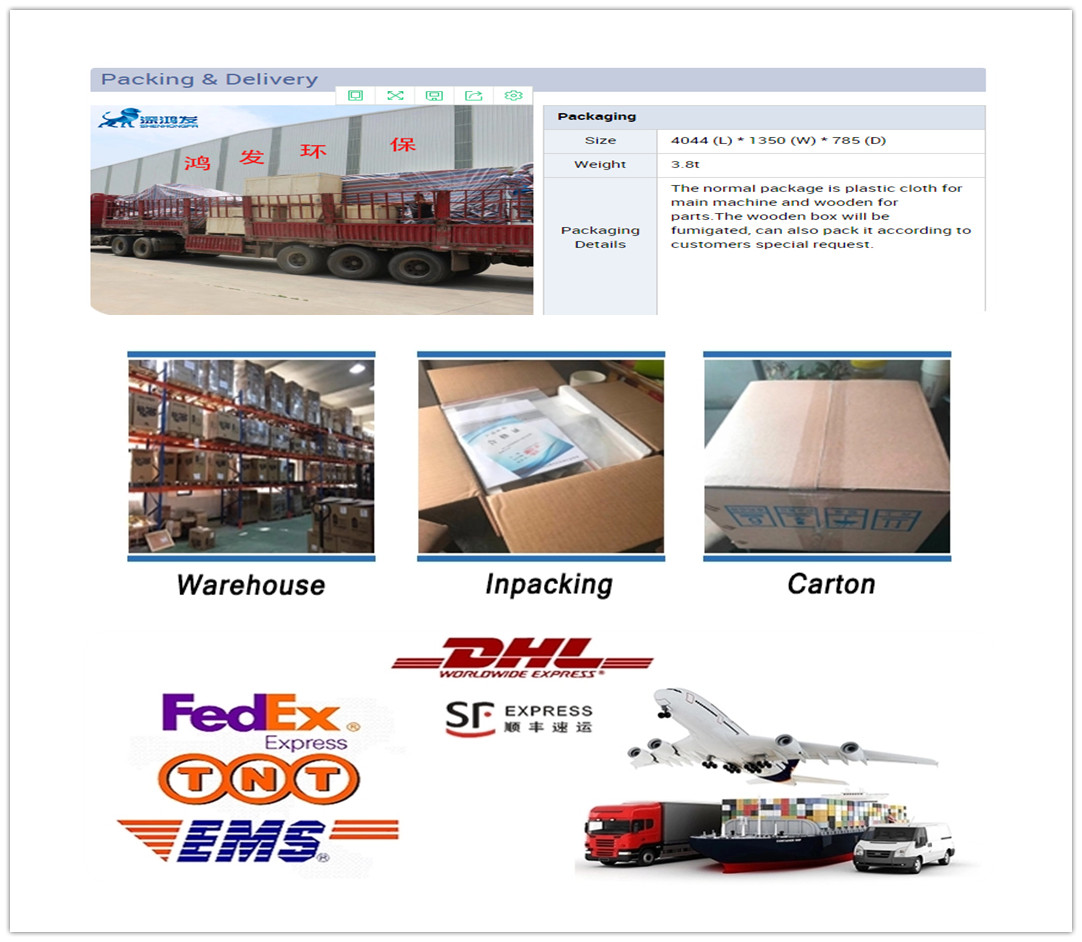

- Ocean, Land, Air, Express

- Port:

- SHENZHEN, TIANJIN, SHANGHAI

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 100sets/month |

| Supply Ability: | 200sets/month |

| Payment Type: | T/T,L/C,Paypal |

| Incoterm: | FOB,CIF,EXW,FAS |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 84212910.90 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN,TIANJIN,SHANGHAI |

Automatic Food Oil Hydraulic Chamber Filter Press

product description

Hydraulic filter press is a kind of intermittent pressurized filter equipment, which can be used for solid-liquid separation of various suspensions. It is simple and convenient to operate, has good separation effect, and is widely used. It is favored by the majority of users. So, what preparatory work should be done before the hydraulic filter press is operated? What are the precautions in operation? Do you need maintenance after use? How to do daily maintenance? Let's follow Kelsie to discuss the little knowledge about hydraulic filter press!

Operation and maintenance matters

Preparations before folding operation

(1) Whether the number of boards and frames meets the requirements, and it is forbidden to start work when the number of boards and frames is less than the specified number.

(2) Whether the arrangement sequence of the plate and frame meets the requirements, whether the installation is smooth, and whether the contact of the sealing surface is good.

(3) Whether the filter cloth is damaged, the hole of the filter cloth is smaller than the hole of the plate frame and relatively concentric with the hole of the plate frame.

(4) Whether the pipelines are smooth and whether there are any leaks.

(5) Whether the hydraulic system works normally, and whether the pressure gauge is sensitive and easy to use.

Precautions during folding operation

(1) The installation of the filter cloth must be flat and not folded to prevent damage to the plate frame and leakage during compression.

(2) The working pressure of the hydraulic station The maximum working pressure of the rubber and plastic frame shall not exceed 20Mpa.

(3) The filtration pressure must be less than 0.45Mpa, and the temperature of the filter material must be less than 80°C to prevent leakage, deformation and tearing of the plate and frame.

(4) The relief valve of the operating device is to be adjusted to the minimum working pressure for the retraction of the piston.

(5) When the plate frame moves on the main beam, no collision or beating is allowed, and the force should be balanced to prevent damage to the handle and damage to the sealing surface.

(6) The valves for materials, compression, washing liquid or hot water must be activated according to the operating procedures, and must not be activated at the same time.

(7) When cleaning the plate frame and filter cloth after unloading the cake, ensure that the channel is unimpeded, and no residue is allowed to stick on the sealing surface or in the feeding channel.

(8) When the hydraulic system stops operating, the long lever handwheel of the operating device should be normally open, and the short lever handwheel should be normally closed to ensure safety and avoid waste of incoming oil.

Folding for daily maintenance

(1) Pay attention to whether the connecting parts of each part are loose, and should be tightened at any time.

(2) The compression shaft or compression screw should be well lubricated to prevent foreign matter.

(3) The pressure gauge should be calibrated regularly to ensure its sensitivity.

(4) The removed plate and frame should be stored flat to prevent bending and deformation.

(5) Check whether the working pressure of the hydraulic system and the oil volume in the fuel tank are within the specified range every shift.

(6) Clean 46# hydraulic oil should be added to the oil tank, and it should be added after being filtered by an 80-100 mesh filter. It is forbidden to add oil containing impurities or water to the oil tank.

PACKING AND DELIVERY

Our Engineering Project

Advantages of Shenzhen HONGFA Filter Press:

1. Low filter cake moisture;

2. Unmanned operation and cost saving;

3. Resist high temperature and corrosion;

4. Good sealing effect can perfectly avoid leskage;

5. Energy saving high performance chamber filter press with long working life

Related Keywords