Test socket of semiconductor

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 100 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

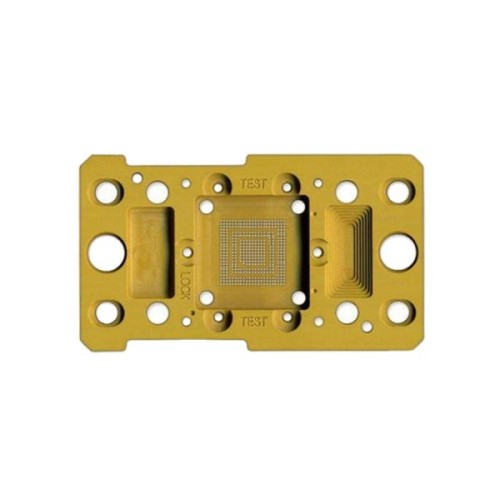

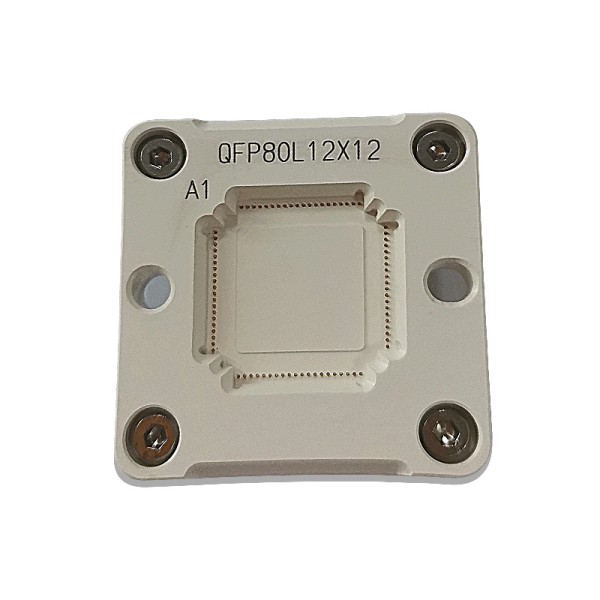

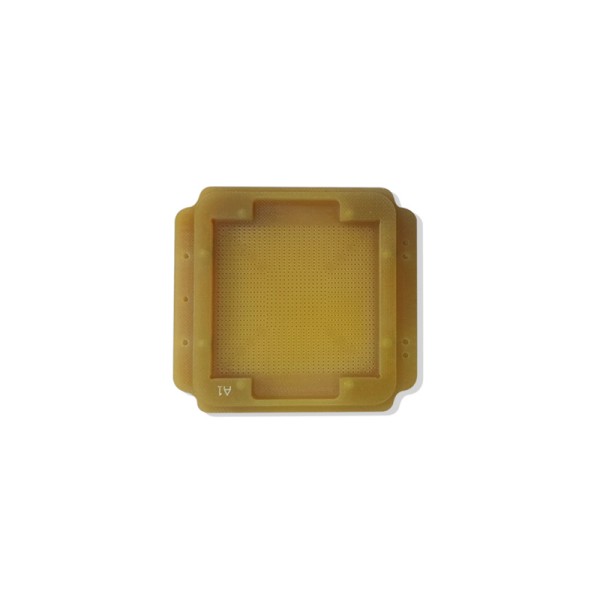

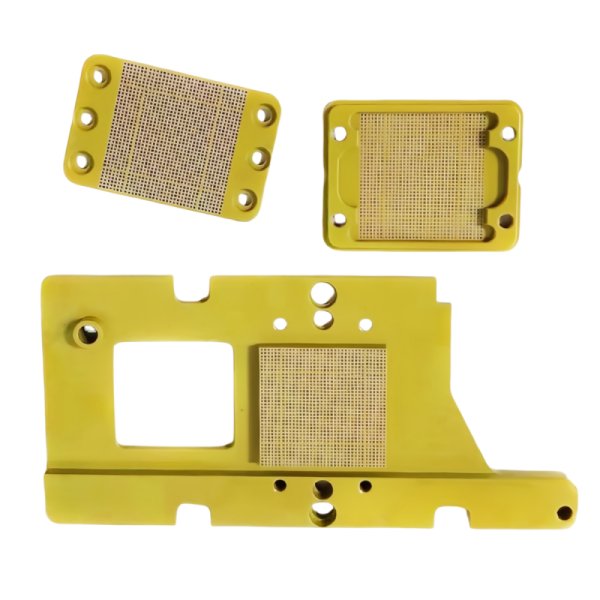

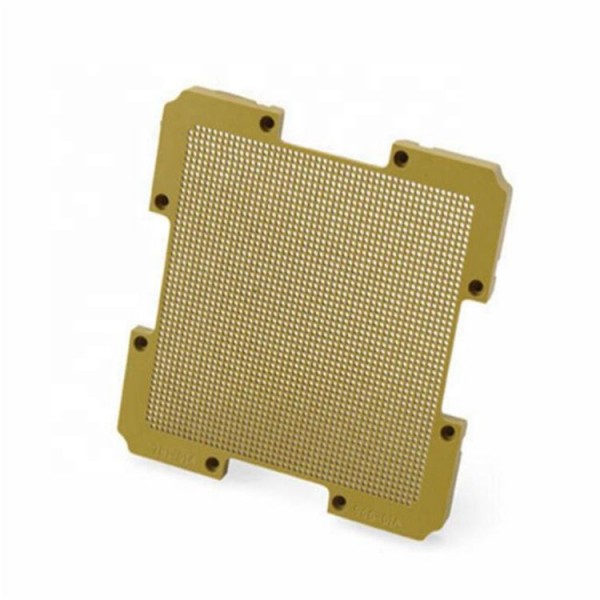

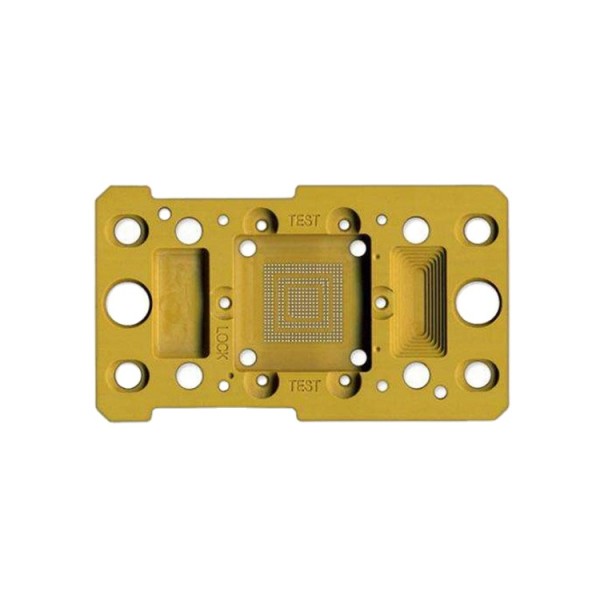

Precision needle mold

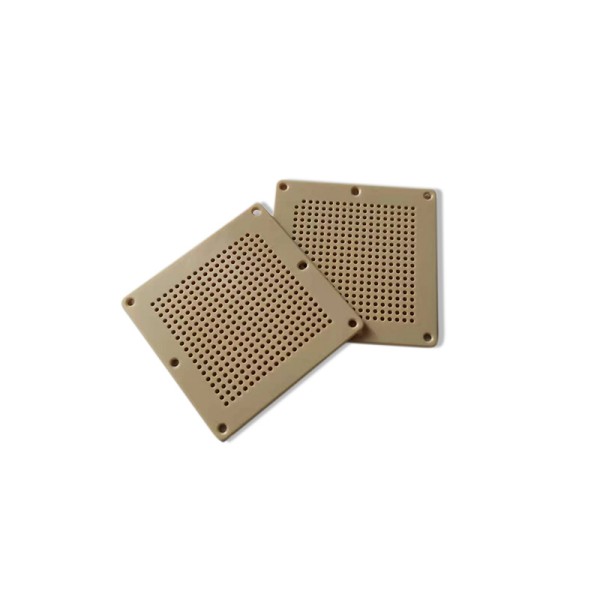

Probe needle mold design and processing has a wealth of experience, hole diameter 0.1mm +-0.01, hole spacing 0.3mm +-0.02, concentricity +-0.02, diameter 0.20mm micro-hole depth of up to 5.0mm, the area can be controlled by the size of the 150MM*150MM area does not distort the flatness of +-0.03, the single-needle plate can be drilled in a high number of 5,000pins. Commonly used needle mold materials: TORLON (polyamide-imide), PEEK, PEI, PEI420, static PEI420, PPS, ULTEM1000, ULTEM230, anti-static ULTEM420 and so on special engineering plastics, to meet the customer from the test to the sample to the mass production of a series of full service.

HONY Plastic has rich experience in the design and manufacture of probe needle mold, small hole diameter 0.1mm +-0.01, hole spacing 0.3mm +-0.02, diameter 0.20mm micro-hole depth of up to 5.0mm, the area can be controlled by the size of the area of 150MM*150MM without deformation flatness +-0.03, single needle plate high pin number can be drilled 5,000pin. Commonly used needle mold processing materials for: TORLON (polyamide-imide), PEEK, PEI, PEI420, static PEI420, PPS, ULTEM1000, ULTEM230, anti-static ULTEM420, and so on, special engineering plastics, to meet the customer from the test to the sample to the mass production of the whole series.

Commonly used products are: connector pin molds, test sockets pin molds, automated test pin molds, test fixtures pin molds.

The introduction of Torlon PAI Microhole Needle Die Test Seats Torlon test sockets material:

PAI polyamide-imide is a modified polyimide, it is a heat resistant amorphous engineering thermoplastic,primarily by trimellitic anhydride and various aromatic diamine condensation.From temperatures of 500°F to chemically harsh environments,TORLON® outperforms similar materials in a broad range of applications.This melt processible plastic offers exceptional toughness,stiffness and strength and is both impact resistant and extremely durable.Available at a lower cost than many advanced engineering plastics,TORLON® can be machined to tight tolerances,extruded and compression molded.

Related Keywords

Related Keywords