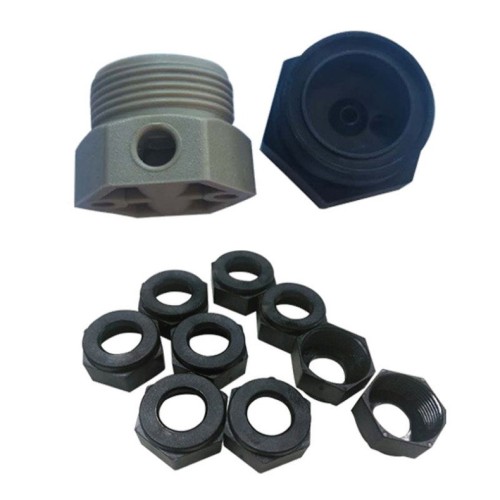

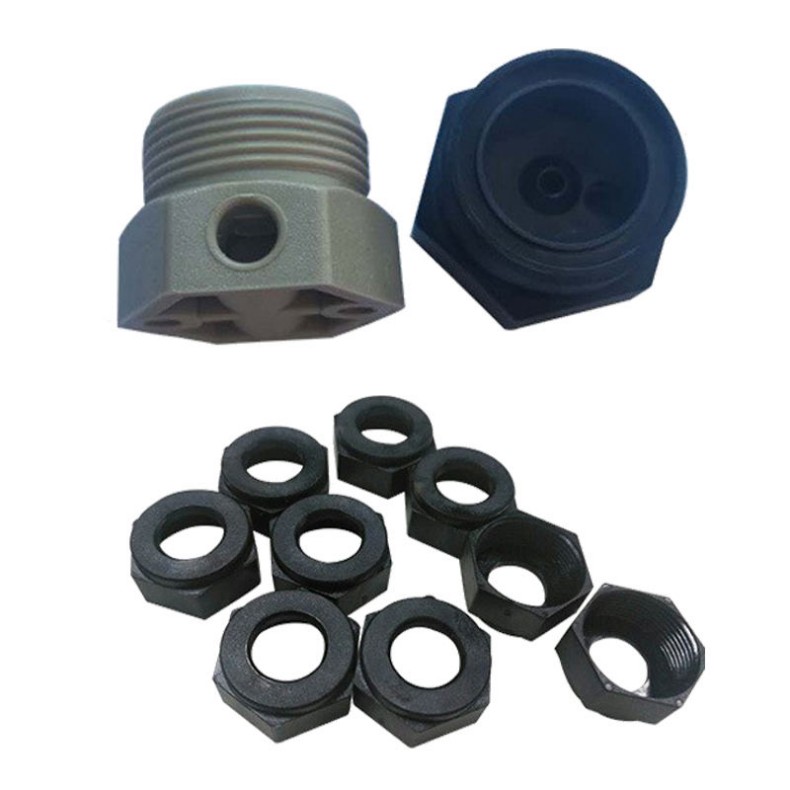

Polyimide injection mold parts

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 100000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

High temperature 300 degrees wear-resistant self-lubricating plastic-PI injection molding grade material introduction

In the vast field of materials science, PI (polyimide) plastics stand out for their excellent wear resistance and high temperature resistance, and have become the material of choice for many high-end applications.PI plastics, known as polyimide plastics, are polymer compounds with high thermal stability and chemical inertness, and their unique molecular structure endows them with extraordinary physical and chemical properties. In this paper, we will discuss the wear resistance and high temperature data of PI plastics in depth, in order to provide reference for the research and application in related fields.

Wear resistance of PI plastics

Wear resistance, as an important indicator of the ability of the material surface to resist wear and tear damage, is directly related to the service life and reliability of the material.PI plastics excel in this regard, mainly due to the high strength and rigidity of its molecular chain, as well as good lubrication and self-repairing ability.

1. Influence of molecular structure

The molecular chain of PI plastics contains a large number of aromatic rings and imide bonds, these structural units not only enhance the rigidity and strength of the molecular chain, but also make the surface of the material when subjected to friction can form a layer of dense protective film, which effectively reduces wear and tear. In addition, the strong interaction between molecular chains of PI plastic is not easy to slip, which further improves its wear resistance.

2. Lubrication and self-repair

In the friction process, the surface of PI plastic can release a trace of lubricating substances, which form a layer of lubricating film between the contact surfaces, reducing the coefficient of friction and reducing wear. At the same time, PI plastic also has a certain self-repairing ability, that is, after slight wear, its surface can restore part of the flatness through the rearrangement of molecular chains and crosslinking, so as to extend the service life.

3. Practical application cases

In the aerospace field, PI plastics are widely used in the manufacture of engine blades, bearings and other key components, and their excellent wear resistance ensures the stable operation of the engine under extreme working conditions. In addition, in the automotive industry, PI plastics are also used in the manufacture of brake pads, transmission gears and other components, which significantly improves the braking performance and transmission efficiency of automobiles.

High Temperature Resistance Data of PI Plastics

High temperature resistance is one of the most recognized characteristics of PI plastics. At high temperatures, PI plastics can maintain stable physical and chemical properties, and are not prone to deformation, decomposition or oxidation, which makes it widely used in many high-temperature, high-pressure, highly corrosive and extreme environments.

High Temperature Stability

The glass transition temperature (Tg) of PI plastics is usually above 250°C, and some special varieties can even reach 400°C or more. This means that PI plastics can maintain their mechanical properties and dimensional stability at temperatures much lower than their decomposition temperature, and will not soften or deform at high temperatures.

2. Heat aging resistance

When working in a high temperature environment for a long period of time, materials tend to undergo thermal aging phenomenon, resulting in performance degradation. However, with its excellent heat aging resistance, PI plastics can maintain high mechanical properties and electrical insulation properties even when used for a long time at high temperatures, which is especially important for electronic and electrical appliances, aerospace and other fields.

3. Mechanical properties at high temperatures

Under high temperature conditions, the mechanical properties of many materials will be greatly reduced, but PI plastic can maintain high strength and toughness in a wide range of temperatures. This makes PI plastics more widely used in high temperature environments, such as for the manufacture of high temperature bearings, seals, heat insulation materials and so on.

4. Examples of high temperature data

In the thermal protection system of spacecraft, PI plastic is often used as a heat insulation layer material, and its excellent high-temperature resistance can effectively block the external high-temperature heat flow on the spacecraft internal invasion. In addition, in the electronics industry, PI plastics are also widely used in the manufacture of circuit boards, connectors and other components in high-temperature environments to ensure the stable operation of electronic equipment.

In summary, PI plastics occupy a pivotal position in the field of material science with its excellent wear resistance and high temperature resistance data. With the progress of science and technology and the continuous expansion of applications, the performance of PI plastics will continue to optimize and improve, providing strong support for the development of more fields. In the future, with the continuous emergence of new materials and technological innovation, the application prospects of PI plastics will be broader, contributing more to the progress of human society.

Related Keywords

Related Keywords