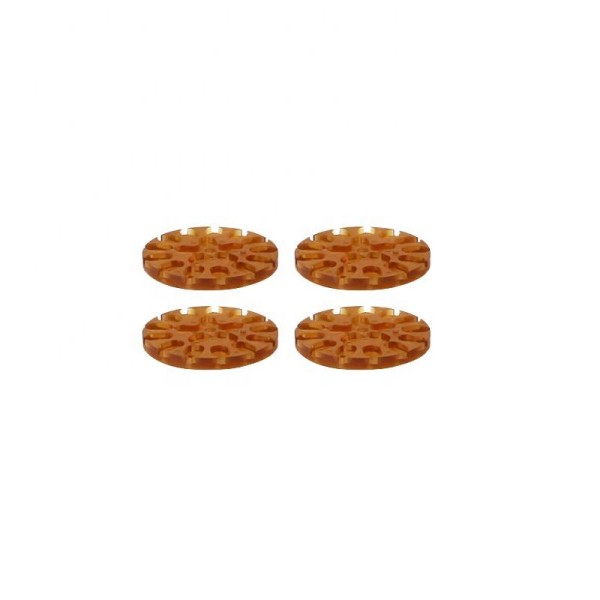

PI cnc machining parts

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 100 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

Aromatic polyimide (polyimide , PI ) is the best overall performance of one of the organic polymer materials, it has corrosion resistance, fatigue resistance, high temperature resistance, abrasion resistance, impact resistance, low density, low noise, long service life, etc., as well as excellent performance in high and low temperatures (long-term -269 ℃ to 280 ℃ invariance); thermal decomposition temperature can be as high as 600 ℃, is the polymer in the heat stability so far Thermal decomposition temperature can be as high as 600℃, which is one of the highest varieties of polymers in thermal stability so far, and will not be brittle in liquid helium at -269℃. It has been widely used in aerospace, aviation, space, automobile, microelectronics, nano, liquid crystal, separation membrane, laser, electrical appliances, medical devices, food processing and many other high-tech fields, and is known as the “problem solver”.

Polyimide is a high-performance thermoplastic engineering plastics, not only has excellent heat resistance, mechanical, dielectric, corrosion resistance and radiation resistance and other properties, but also shows excellent thermal processing properties, can be hot molding, extrusion and injection molding methods.

Polyimide can be compounded with glass fiber, carbon fiber, PTFE, graphite, etc., which significantly improves the mechanical properties and self-lubricating properties of polymer materials.

Polyimide can be made into films, can also be molded into tubes, rods and complex structures of confidential parts, such as gears, sealing rings, bearings and connectors. In specific cases for a replacement of metals, ceramics, thermosetting resins, low-temperature thermoplastics and most difficult to heat processing molding polyimide ideal materials.

Main properties of polyimide:

Outstanding easy thermal processing properties

Excellent heat resistance

Excellent mechanical properties

Excellent dielectric properties

Excellent corrosion resistance

Good friction properties (self-lubricating, wear resistant)

No release of small molecules during processing

Low hygroscopicity

Flame retardant and radiation resistant

Can be reused

Self-extinguishing polymer with low smoke generation

Non-toxic

Areas of application

1. Main application areas: polyimide as a cutting-edge material with outstanding performance, with its excellent electrical insulation, wear resistance, high temperature resistance, radiation resistance and physical and mechanical properties, in industrial machinery, electrical and electronic appliances, instrumentation, petrochemicals, construction machinery, commercial equipment, metrology, analytical, medical equipment, as well as transmission and textile equipment and other areas of rapid growth in the application of the world's rockets, aerospace, aircraft and other It has become one of the indispensable materials for global rockets, astronautics, airplanes and other cutting-edge technology fields. With the continuous and rapid development of aerospace, automotive, and especially the electronics industry, there is an urgent need for miniaturization, lightweight, high functionality and high sustainability of electronic equipment. Polyimide with excellent performance in these areas have a great deal to do, and the current growth rate has been maintained at about 20%, with broad prospects for development.

2. Electronic appliances and semiconductors: printed circuit boards, electrical connectors and insulators, connectors, gaskets, LCD monitors and chip holders, high-temperature sockets, connectors, computer hard disks, integrated circuits, chip carriers, insulating materials, heat-resistant cables, terminal blocks, sockets, and so on.

3. Automobiles and aircraft: engine combustion system parts, jet engine components, compressor and generator parts, fasteners, spline joints and electronic contacts, oil pumps and air pump covers, piston rings, gears, blades, bearings, bearing retainers and gaskets, etc., both to reduce the weight of the components, but also to extend the service life of the components.

4. Analytical and medical equipment: valves, valve seats, fittings and connectors, etc.

5. Industrial machinery: such as motors, pumps and compressors, high temperature resistant self-lubricating bearings, bushings, bushings, insulating parts, sealing rings, piston rings, gears, compressor blades and piston machines, equipment heat shields, thrust washers, etc.

6. Commercial machinery: heat-resistant parts for high-speed copiers and laser printers, paper separating claws, roller shaft end caps, heat-resistant gears, rotating pads and drive couplings.

Related Keywords

Related Keywords