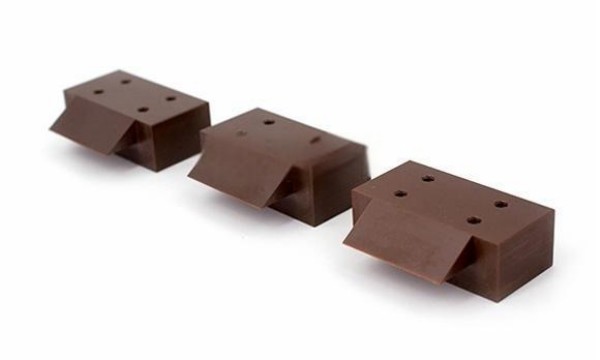

PI Polyimide Machining PI Parts

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 100 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

Polyimide (PI) is an aromatic heterocyclic polymer compound with imide-based links in its molecular structure, which is one of the best heat-resistant varieties of engineering plastics and is widely used in the fields of aeronautics, spaceflight, microelectronics, nanotechnology, liquid crystals, lasers, etc. Recently, countries have included the research, development and utilization of PI in the development of new chemical materials in the 21st century.

Recently, all countries are including the research, development and utilization of PI in the 21st century as one of the development focuses of new chemical materials, and PI has great application prospects because of its outstanding features in performance and synthesis, either as structural materials or as functional materials.

PI is known as the top of the pyramid of polymer materials, also known as the “problem solver”, and even some industry insiders believe that “no PI would not have today's microelectronics technology.

Polyimides (PI) are high-performance polymers of imide monomers containing two nitrogen (N)-bonded acyl groups (C=O). These polymers are known for their high temperature performance in the 400-500°C range as well as their chemical resistance.

In many industrial applications, they are used to replace the traditional use of glass, metal and even steel.

Polyimides have excellent mechanical properties and can therefore be used in applications that require strong organic materials, for example:

High temperature resistant fuel cells

Flat panel displays

Aerospace applications

Chemical and environmental industries

and various military applications

They are used as plastics, films, laminating resins, insulating coatings and high-temperature structural adhesives.

Polyimides are available in two forms: thermoset and thermoplastic.

PI can be divided into thermosetting and thermoplastic, can be divided into poly(tetramethylene tetracarbimide) (PMMI), polyetherimide (PEI), polyamide monoimide (PAI), etc., have their own uses in different fields.

PMMI in 1.8 MPa load heat distortion temperature of 360 ℃, excellent electrical properties, can be used for special conditions of precision parts, high temperature self-lubricating bearings, seals, blower impellers, etc., can also be used in contact with liquid ammonia valve parts, jet engine fuel supply system parts.

PEI has excellent mechanical properties, electrical insulation properties, irradiation resistance, high temperature resistance and wear resistance, high melt flow rate, molding shrinkage rate of 0.5% to 0.7%, available for injection and extrusion molding, post-processing is easier, can also be used for welding method and other materials combined in the electronics and electrical appliances, aerospace, automotive, medical equipment and other industries are widely used.

The strength of PAI is the highest among the current non-reinforced plastics, the tensile strength is 190 MPa, the bending strength is 250 MPa, and the heat distortion temperature is as high as 274 ℃ under the load of 1.8 MPa. PAI has good resistance to ablative corrosion and electromagnetism at high temperatures and frequencies, and it has good adhesive properties to metals and other materials, and it is mainly used for the gears, bearings, and the separating claws of photocopying machines, etc., and it can be used for the ablative materials of aircrafts, transmittance materials, and other materials, and can be used in the production of electronic devices. It is mainly used for gears, bearings and separating claws of copiers, etc. It can also be used for ablative materials, permeable materials and structural materials of aircraft.

Related Keywords

Related Keywords