PA pipe mc nylon tube bushing

-

$3.901-99 Kilogram

-

$3.80100-999 Kilogram

-

$3.70≥1000 Kilogram

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- SHENZHEN, GUANGZHOU, HONGKONG

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | Enough |

| Supply Ability: | Enough |

| Payment Type: | T/T,Paypal |

| Incoterm: | DDU,EXW,DES,CIF,DAF,CFR,FOB |

| Certificate: | ROHS, REACH , ISO , SGS |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | SHENZHEN,GUANGZHOU,HONGKONG |

HONY®Nylon is developed by Carothers, an outstanding scientist in the United States, and a research team under his leadership. It is the first synthetic fiber in the world. The appearance of nylon has brought a new look to textiles. Its synthesis is a major breakthrough in the synthetic fiber industry and an important milestone in polymer chemistry. Nylon, polyamide (PA) is a general term for thermoplastic resins containing repetitive amide gene - [NHCO] - in the main chain of molecules. It includes aliphatic PA, and aliphatic PA is a good aromatic PA. Among them, aliphatic PA has many varieties, high yield and wide application. Its name depends on the specific number of carbon atoms in the synthetic monomer.

On October 27, 1938, the world's first synthetic fiber was officially announced and polyamide 66 was named Nylon.

Nylon has many characteristics. Therefore, it is widely used in automobile, electrical equipment, machinery, transportation equipment, textile and paper-making machinery. With the miniaturization of automobiles, high performance of electronic and electrical equipment, the process of lightweight mechanical equipment is speeding up, and the demand for nylon will be higher and greater. In particular, nylon as a structural material. The inherent shortcomings of nylon are also an important factor restricting its application. Especially for PA6 and PA66, compared with PA46.PA12 and other varieties, nylon has a strong price advantage, although some properties can not meet the requirements of the development of related industries. Therefore, it must be targeted at a certain industry. In the application field, some properties of PA can be improved by modification to expand its application field. Because of the strong polarity of PA, it has strong hygroscopicity and poor dimensional stability, but it can be improved by modification.

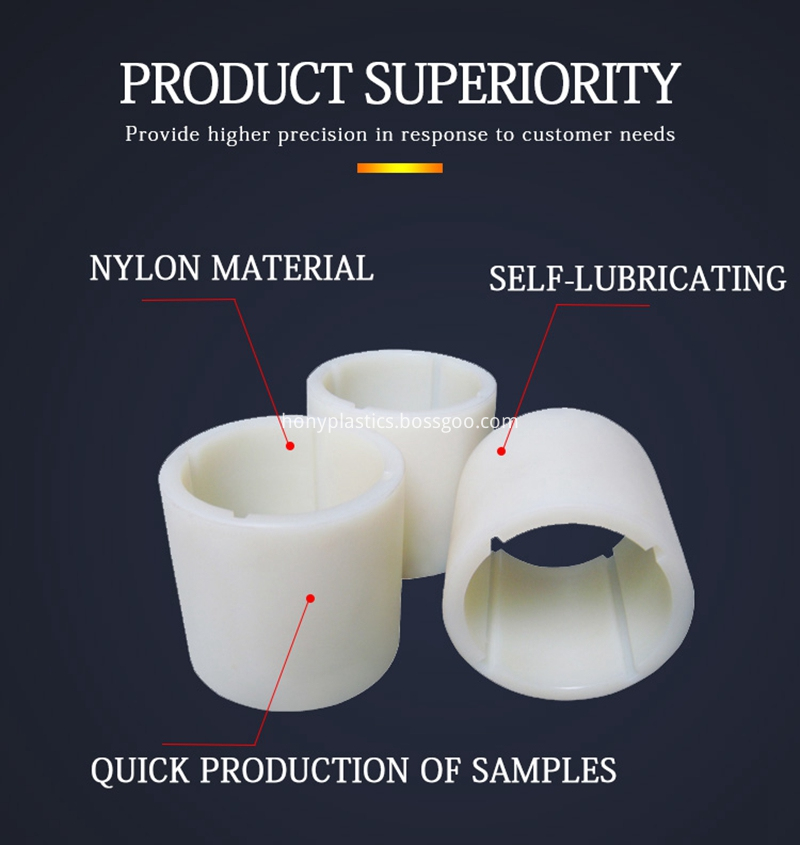

Product advantages

High strength and stiffness at high temperature

Good impact strength, even at low temperature

Very good flow for easy processing

Good abrasion and wear resistance

Excellent fuel and oil resistance

Good fatigue resistance

Good electrical insulating properties

Low dimensional stability

Attacked by strong mineral acids and absorbs polar solvents

Proper drying before processing is needed

Application

It can be used in automobile pressure braking, power steering, brake pipeline, transmission control system, etc.

Can be used for hydraulic conveying system and hydraulic control system of construction machinery

Can be used for hydraulic operation and control system of machining equipment

Can be used for high-pressure painting pipes, liquid resin transfer pipes, boilers and pipe cleaning special pipes

Can be used in textile factories, vehicles, ship machinery, fuel delivery, vacuum systems, air conditioning systems

Our strengths

● Factory direct sale with negotiable price.

● Better quality compared with similar suppliers.

● With certificate ISO/RoHS.

● Accept Customization.

● hours prefessional service.

● Support payment terms as per your request.

● Bulk stock.

● Quick shipping within 3 days.

HONY®PA Properties Data Sheet

| Item | Method | Unit | Value |

| Machanical Properties | |||

| Specific gravity | ASTM D792 | g/cm3 | 1.14 |

| Tensile yield strength | ASTM D638 | MPa | 74 |

| Breaking elongation | ASTM D638 | % | 5 |

| Bending strength | ASTM 790 | MPa | 90 |

| Flexural modulus | ASTM 790 | MPa | 2200 |

| Shore hardness | ASTM D2240 | D | 85 |

| Impact strength | ASTM D256 | J/M | 50 |

| Thermal Properties | |||

| Melting point | DSC | ℃ | 220 |

| Heat distortion temperature | ASTM D648 | ℃ | 70 |

| Operating temperature (long term) | - | ℃ | 85 |

| Opertation temperature(short term) | - | ℃ | 160 |

| Thermal conductivity | DIN 52612-1 | W/(K-M) | 0.23 |

| Coefficient of linear thermal expansion | ASTM D696 | 10-5-1-/K | 8 |

| Electrical Properties | |||

| Dielectric strength | ASTM D150 | KV-mm | 25 |

| Dielectric loss factor | ASTM D150 | - | 0.032 |

| Volume resistivity | ASTM D257 | Ω.cm | 10^14 |

| Surface resistivity | ASTM D257 | Ω | 10^16 |

| Dielectric constant | ASTM D149 | - | 4.2 |

| Chemical Properties0.1 | |||

| Water absorption | 23℃ 60%RH | % | 1.28 |

| Acid resistance | 23℃ 60%RH |

|

- |

| Alkali resistance |

|

|

+ |

| Acid and alkali resistance |

|

|

+ |

| Resistance to sodium chlorate |

|

|

0 |

| Resistance to aromatic compounds |

|

|

+ |

| Resistance to ketone | 23℃ 60%RH |

|

+ |

| Resistance to hot water | 23℃ 60%RH |

|

+ |

| Others | |||

| Flammability | UL 94 |

|

HB |

| Viscosity | - |

|

+ |

| Non totix | EEC 90/128 FDA |

|

+ |

| Coefficient of friction | DIN 53375 |

|

0.36 |

| Anti-ultraviolet | - |

|

- |

Remarks:

1.“+”: positive “-”: negative “0”: depends on condition.

2. All the parameters above are based on raw material but not finished products.

Main product

Related Keywords