Rigid Black PVC Roll for Vaccum Forming

- Min. Order:

- 1 Roll/Rolls

- Min. Order:

- 1 Roll/Rolls

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

PVC black sheet: a new choice for high temperature resistance and flame retardancy

Polyvinyl chloride, or PVC for short, is a widely used general-purpose plastic. It was once one of the world's largest plastics in terms of production, involving applications in a number of fields, including building materials, industrial products, daily necessities, floor leather, floor tiles, artificial leather, pipes, wires and cables, packaging films, bottles, foaming materials, sealing materials, and fibers.

Construction field: PVC sheet has a wide range of applications in the construction industry, such as floor leather, floor tiles, etc., with good durability and aesthetics.

Industrial products: PVC sheets and coils can be used in various industrial products, such as pipes, wires and cables, etc., with good heat resistance and flame retardancy.

Daily necessities: PVC sheet also has a wide range of applications in the field of daily necessities, such as packaging film, bottles, etc., with good transparency and toughness.

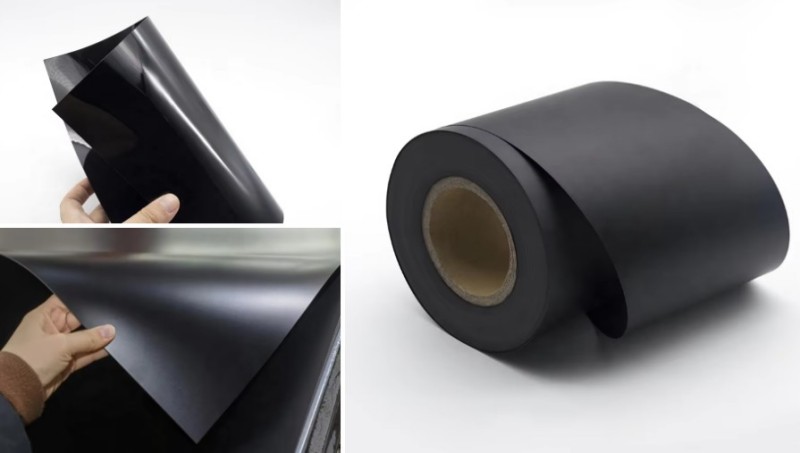

Customization and Punching: PVC sheet can be customized according to the demand, the size specification can be customized, and it can be punched arbitrarily to meet different needs.

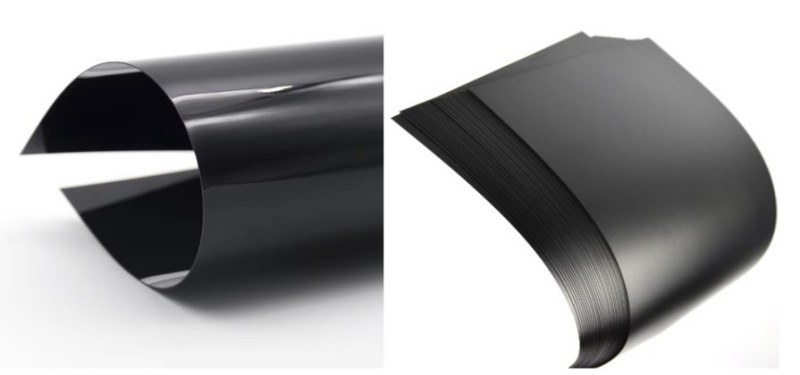

Smooth as mirror: PVC glossy black sheet surface is smooth as mirror, with good visual effect and touch feeling.

ELASTIC MATERIAL: PVC sheets are elastic and can adapt to different bending and pressure.

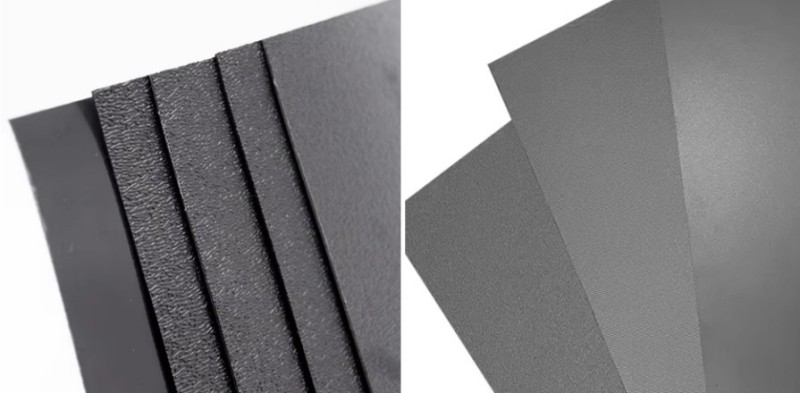

SIZE SPECIFICATIONS: PVC sheets are available in a variety of sizes and specifications, which can be customized to meet the needs of different projects.

PVC glossy black sheet not only has good high temperature resistance and flame retardant properties, but also widely used in various fields.

The difference between PC sheet and PVC sheet is mainly reflected in the chemical composition, physical properties, chemical resistance, application areas and processing technology.

Chemical composition and physical properties

PC (polycarbonate): PC is a kind of engineering plastics, with high transparency and excellent impact resistance, its molecular structure contains ester bond and hydroxyl, mainly through the polymerization reaction made. pc's impact resistance is extremely strong, even dozens of times higher than the glass, and at the same time has good heat resistance.

PVC (polyvinyl chloride): PVC is a general-purpose plastic made by polymerizing hydrogen chloride and vinyl monomer, with chlorine in the molecular structure, which gives it good corrosion and chemical resistance.PVC usually has high rigidity and good abrasion resistance, but its impact resistance is relatively poor, and it is easy to break when subjected to strong impacts. Rupture

Chemical Resistance

PC: has poor resistance to certain solvents and chemicals and requires special care when used.

PVC: Good resistance to many chemicals, especially acids and alkalis, so it is commonly used in chemical piping, valves, and other applications where chemicals come into contact with them.

Application Areas

PC: Due to its excellent strength and transparency, PC is mainly used in applications such as optical lenses, protective eyewear, automotive lampshades and electronic product housings. It also plays a role in products that require high strength and transparency, such as cell phone screens and other display devices.

PVC: Widely used in construction materials, pharmaceutical packaging, pipes, plastic doors and windows and cable insulation. Due to its high chemical resistance and low cost, PVC has a wide range of civil and industrial applications

Processing

PC: the processing process is more complex, can be processed through thermoforming, stamping, cutting and other processes to adapt to a variety of complex shapes and design needs

PVC: The processing technology is relatively simple, and commonly used methods include extrusion, injection molding and blow molding. Due to the low melting point of PVC, lower temperatures can be used during processing, thus saving energy and time.

In terms of physical properties, PC shows clear advantages. It has higher strength, rigidity and toughness, and is extremely impact resistant. In contrast, PVC is relatively brittle and not as strong or tough as PC.

PC is generally more transparent than PVC, which makes it a better performer in optical applications.

In terms of heat resistance, PC performs well and maintains its performance at higher temperatures, whereas PVC's heat resistance is relatively poor.

In terms of weathering, PC has a strong weathering ability and can be used for a long time in outdoor environments without much impact on its performance; PVC may experience aging and discoloration when used outdoors.

In terms of price, generally speaking, the price of PC is higher than that of PVC.

As a result of these differences in properties, there are also differences in their uses; PVC is often used in piping, wire and cable jackets, films, sheets, etc. PC, on the other hand, is more demanding in terms of performance. PC is widely used in electronic and electrical appliances, automotive industry, building materials, optical instruments and other fields due to its high performance requirements.

In short, PVC and PC each have their own characteristics, and the choice of use should be based on specific needs and application scenarios to decide. Whether you are looking for affordable PVC or high performance PC depends on your actual needs.

Related Keywords

Related Keywords