PVC Rigid Sheets Polyvinyl Chloride

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- SHENZHEN, GUANGZHOU, HONGKONG

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 10000 |

|---|---|

| Supply Ability: | 10000 |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN,GUANGZHOU,HONGKONG |

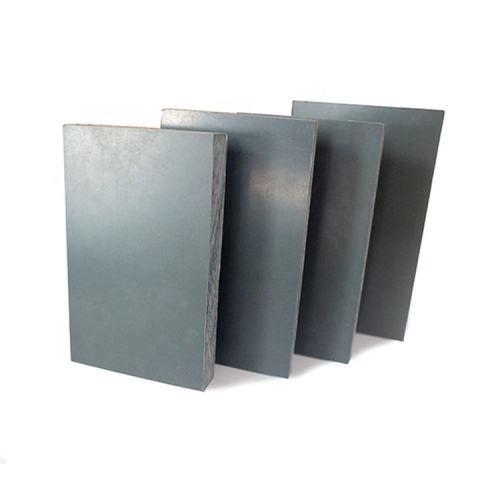

HONY®Polyvinyl Chloride (PVC)Rigid sheet is extruded from Environmental friendly compound having smooth & glossy surface finish and PVC is commonly employed in the construction of tanks, valves, and pipe systems.

Polyvinyl Chloride (PVC) is a flexible and rigid substance that is chemically inert. PVC is extremely resistant to weather and corrosion resistance. It has a great weight-to-strength ratio and is an excellent thermal and electrical insulation. The most frequently utilized in the Vinyl family PVC can be cured and welded, machined bent, and shaped quickly.

PVC Type 1– Normal impact, excellent chemical and corrosion resistance, easy to fabricate, weld or machine.

Clear PVC Type 1– Offering superior chemical resistance and favorable impact strength, clear PVC is an excellent substitute for transparent plastics such as acrylic and polycarbonate. UL 94 V-0 rating makes it a favorable choice for applications that need flame retardant materials for sight windows and transparent dividers in semiconductor, pharmaceutical, and even food service or processing settings. Clear PVC can be heat formed and easily machined or fabricated.

PVC Properties and Material Options

PVC Type 2– High impact, excellent chemical and corrosion resistance, easy to fabricate, weld or machine.

CPVC– High heat and corrosion resistant CPVC sheet. Excellent corrosion resistance at elevated temperatures.

PERFORMANCE CHARACTERISTICS:

PVC IS WIDELY USED FOR:

TYPICAL PROPERTIES OF PVC

OPTIONS AVAILABLE

UNITS

ASTM TEST

PVC (RIGID)

Tensile strength

psi

D638

7,500

Flexural modulus

psi

D790

481,000

Izod impact (notched)

ft-lbs/in of notch

D256

1.0

Heat deflection temperature @ 264 psi

°F

D648

158

Maximum continuous service temperature in air

°F

140

Water absorption (immersion 24 hours)

%

D570

0.06

Coefficient of linear thermal expansion

in/in/°Fx10-5

D696

3.2

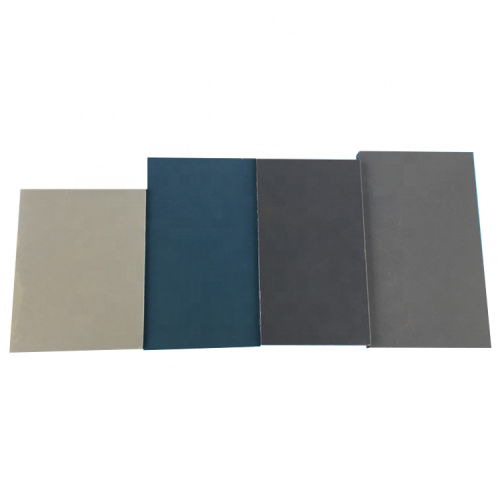

COLOR

Sheet:

Gray, White, Clear

Antimicrobial Panel:

White, Beige, Ocean Blue, Green Grape

Rod:

Gray, White, Black

GRADES

Type 1, Type 2, CPVC,

Antimicrobial Panels,

SHEET

Dimensions:

12 in x 12 in – 60 in x 120 in

Thickness:

0.062 in – 4 in

PANELS

Dimensions:

Antimicrobial Panel

48 in x 96 in – 48 in x 120 in

Interlocking Liner Panel

16 in x 96 in – 16 in x 240 in

Thickness:

Antimicrobial Panel

2 mm – 2.5 mm

Interlocking Liner Panel

0.5 in (12.7 mm)

ROD

Outside Diameter:

0.250 in – 14 in

Related Keywords