PTFE P84 compounds material

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | Enough |

|---|---|

| Supply Ability: | Enought |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,DDU |

| Certificate: | ISO SGS REACH ROHS |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shenzhen,Guangzhou,Hongkong |

Polyimide P84®NT is available as neat polymer as well as blended with functional fillers. Standard compounds contain 15% or 40% graphite, 15% MoS2 or 15% graphite combined with 10% PTFE. Moreover, develop- ing custom-tailored solutions with proprietary formula- tions are possible.

The reinforcement of PTFE (chemically named polytetrafluoroethylene) with high-performance polymers offers many advantages compared to inorganic fillers. The most important property is the excellent wear resistance without abrasion of the sliding partner.TECAPOWDER P84 (based on Evonik's P84®) is an active filler in PTFE. This is characterized by a highly increased creep resistance and a good mechanical bonding of the powder to the substrate.

The extremely fine powder developed leads to excellent surfaces on processed parts and peel films of these compounds.

PTFE compounds with P84 added for improved performance

The most important properties of P84-filled polytetrafluoroethylene , are excellent wear resistance at elevated temperatures, high elongation, and no wear on the sliding partners - all without lubrication.

P84, as an active filler in PTFE, improves the mechanical properties of PTFE. Doping PTFE with 5-20% TECAPOWDER P84 VPD creates wear-resistant PTFE compounds that extend the performance range of standard PTFE materials, especially at high pressures, high speeds, and high temperatures. tecapowder p84 polyimide-filled PTFE compounds run particularly well in mating surfaces with soft mating surfaces.

Good chemical resistance

Very good sliding and wear properties

High toughness

Low friction and wear

High electrical insulation

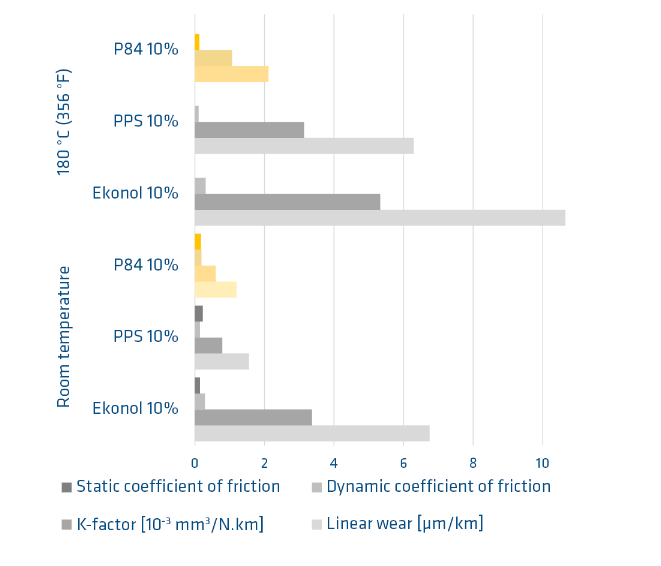

Tribological properties of PTFE compounds on steel compared to PPS or Ekonol as fillers

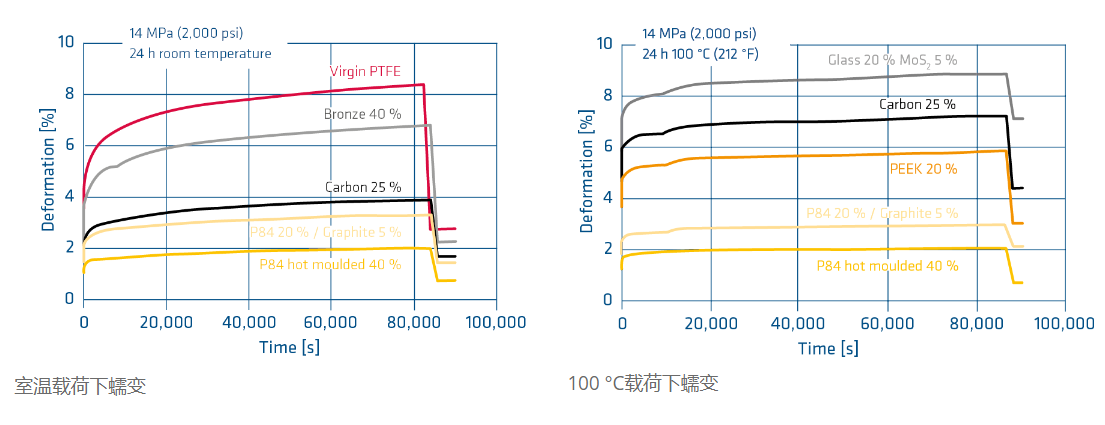

Creep under load

K-factor on different sliding surfaces

TECAPOWDER P84 - Your Reliable Partner

TECAPOWDER P84 resins are produced in different particle size distributions, fillers and grades depending on the intended end use and processing method.

HCM (Hot Compression Molding) grades can be produced without fillers or with fillers such as graphite powder for die casting or press extrusion molding or direct molding into finished parts.

VPD (Vacuum Pre-Dried) grades can be used as low saturation fillers in PTFE materials. The addition of 5-20% TECAPOWDER P84 VPD to PTFE creates wear-resistant PTFE compounds that extend the performance range of standard PTFE materials, especially at high pressures, high speeds, and high temperatures.P84 polyimide-filled PTFE compounds run well on soft matching surfaces. Standard unsintered process conditions of PTFE are used for casting these compounds.

P84® is a registered trademark of Evonik Industries or its subsidiaries.

Related Keywords