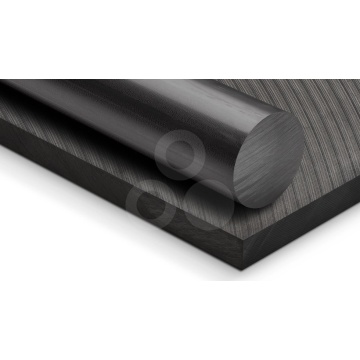

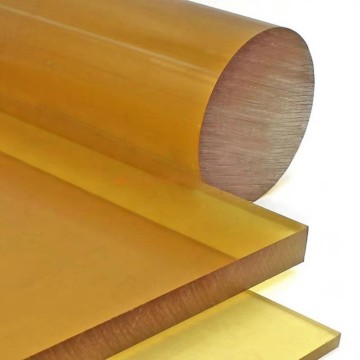

Ensinger TECASON™ P MT Polyphenylsulfone (PPSU)

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU,DDP |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

PPSU plastic (polyphenylsulfone) comes in a range of grades to suit a wide variety of applications mainly to suit the food & medical industries. TECASON PPSU plastic is suitable for super heated repetitive steam sterilisation & offers extremely high dimensional stability, very high impact strength & chemical resistance at continuous service temperatures between -50°C to +170°C. Superior product to standard PSU.

TECASON® P is a PPSU (polyphenylsulfone) grade offering a level of performance above polysulfone grades. It has increased temperature-, impact- & chemical resistance properties as well as excellent resistance to repeated steam sterilization (autoclave) cycles. It exhibits high thermal & mechanical capacity, high strength, high dielectric strength and good machinability. It can be processed using injection molding. Target industries include medical technology, electronics, food processing and process engineering.

TECASON® P MT is a biocompatible PPSU (polyphenylsulfone) grade. It is available in several colored and transparent grades, as well as with x-ray opaque XRO additive which allows for clear component visibility on fluoroscopy and X-ray. Exhibits exceptional resistance to repeated steam autoclaving without loss of dimensional stability or physical properties. Also exhibits excellent impact strength, high tensile strength, very high resistance to environmental stress, great mechanical strength and high dielectric strength and stability. It can be processed using injection molding. Target industries include medical technology (surgical tools & instruments) and pharmaceutical industry. Compliant with cytotoxicity according to ISO 10993-5 and meets requirements for USP Class VI.

TECASON® P MT XRO ® is a PPSU (polyphenylsulfone) grade. It exhibits high thermal & mechanical capacity, good heat deflection temperature, hydrolysis & superheated steam resistance, good impact strength, high gamma radiation resistance, good chemical resistance and high strength. It can be processed using extrusion. Target industries include medical technology.

TECASON® S is a PSU (polysulfone) grade known for its chemical resistance, rigidity, high-temperature performance, and its ability to operate in an autoclave environment. Maintains dimensional stability and mechanical performance through repeated autoclaves. It exhibits high thermal & mechanical capacity, high creep resistance, high strength and excellent electrical properties. Holds excellent mechanical properties over a wide range of temperature. It can be processed using injection molding. Target industries include medical technology, electronics, pharmaceutical industry and semiconductor technology. Complies with FDA (U S Food and Drug Administration) and NSF (National Science Foundation).

PPSU plastic has the following characteristics:

High operating temperature (180 degrees Celsius)

good chemical compatibility

Excellent resistance to hydrolysis (suitable for repeated steam sterilization)

High rigidity for various temperatures

Very high impact strength

ideal dimensional stability

Excellent resistance to high energy radiation (gamma and X-rays)

good electrical insulation properties

ideal dielectric properties

Wide range of Application :

1. It is suitable for making heat-resistant parts, insulating parts, wear-reducing and wear-resistant parts, instrumentation parts and medical equipment parts. Polyarylsulfone is suitable for making low-temperature working parts.

2. Polysulfone is commonly used in the electronic and electrical industry to manufacture integrated circuit boards, coil tube frames, contactors, sleeve frames, capacitor films, and high-performance alkaline battery casings.

3. Polysulfone is used in household appliances for microwave oven equipment, coffee heaters, humidifiers, hair dryers, cloth steamers, beverage and food dispensers, eating and drinking tableware, water cups, milk bottles, etc. It can also replace non-ferrous metals for precision structural parts such as clocks, copiers, and cameras.

4. Polysulfone has passed the relevant specifications in the fields of medicine and food in the United States, and can replace stainless steel products. Due to the characteristics of polysulfone, such as steam resistance, hydrolysis resistance, non-toxicity, high temperature steam sterilization resistance, high transparency, and good dimensional stability, it can be used as surgical tool trays, sprayers, fluid controllers, heart valves, pacemakers, gas masks, Braces, etc.

Because PPSU is a safe material, it does not contain endocrine-disrupting carcinogenic chemicals (environmental hormone: bisphenol A), and as a material with excellent heat resistance, the heat-resistant temperature is as high as 207 degrees. Because it can be boiled repeatedly at high temperature, it can be sterilized by steam. It has excellent drug resistance and acid and alkali resistance, and can withstand general liquid medicine and detergent cleaning without chemical changes. Lightweight and drop-resistant, it is the best in terms of safety, temperature resistance, hydrolysis resistance and impact resistance. But the price is relatively expensive

Related Keywords