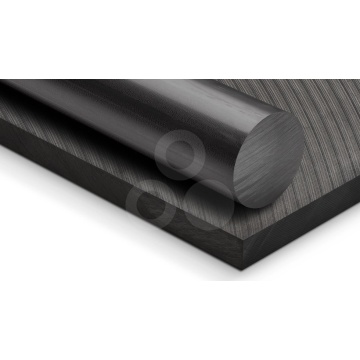

Radel® R-5500 black PPSU rod color

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 100000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shenzhen,Guangzhou,Hongkong |

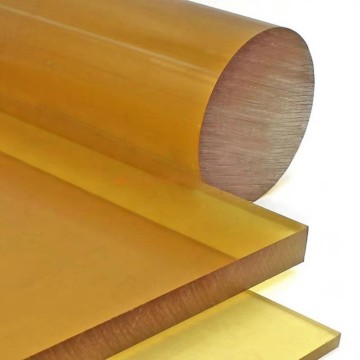

PPSU (chemically known as polyphenylsulfone) is made in standard stock shapes for machining and is usually extruded into a sheet and rod using Radel® PPSU polymer.

PPSU plastic is an amorphous material, which has a high glass transition temperature and low moisture absorption. Furthermore, PPSU material has better impact strength and chemical resistance than PSU and PES from the polysulfone group. Apart from these characteristics, PPSU polymer can withstand sterilization with superheated steam better than other members of this group of polymers, and is resistant to detergents and disinfectants.

Properties of Ppsu Engineering Plastic Sheet

- High operating temperature (180οC)

- Good chemical compatibility

- Excellent resistance to hydrolysis (suitable for repetitive steam sterilisation)

- High rigidity over a wide range of temperatures

- Very high impact strength

- High dimensional stability

- Very good resistance against high energy radiation (gamma and X-rays)

- Good electrical insulating properties

- Favourable dielectric characteristics

Ppsu Virgin Material Ppsu Sheet MATERIALS

- TECASON P - PPSU for industrial applications

- TECASON P MT - PPSU for medical use, biocompatible, different colours

- TECASON P MT XRO - PPSU for medical use, specially modified to be x-ray opaque, biocompatible

Through high pressure steam sterillizing test, PPSU is proved to have the best hydrolysis resistance better than other armorphous plastic.In fact,PPSU can stand million times of high pressure steam sterillizing, which makes PPSU a very good choice for medical application.

Related Keywords