40% Glass Fiber Reinforced PPS

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 100 |

|---|---|

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

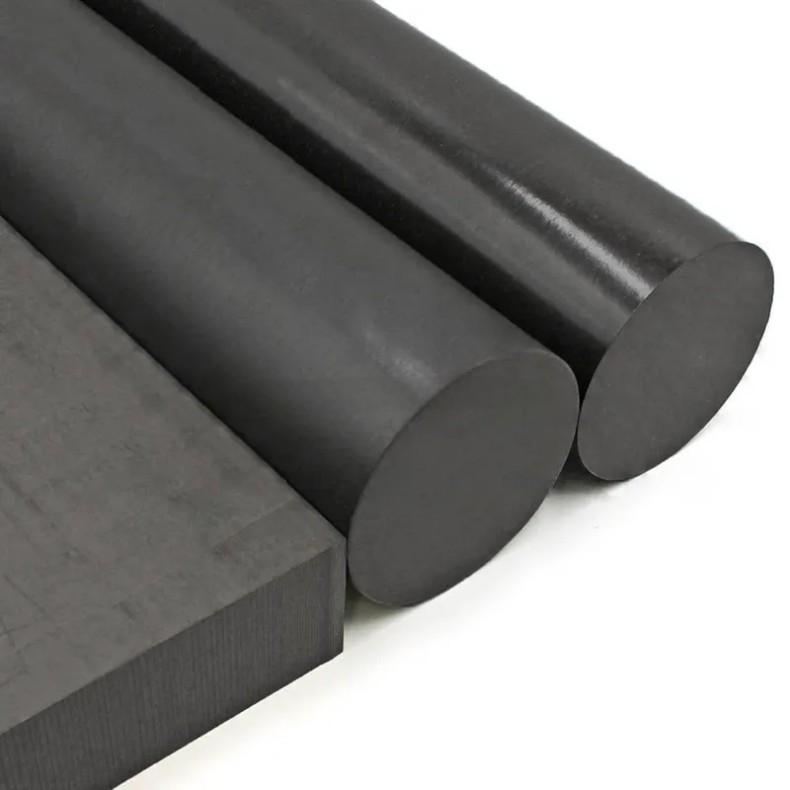

PPS with Glass Fiber 40 material, or PPS with Fiber 40 plastic particles, is a high-performance thermoplastic engineering plastic that combines PPS (polyphenylene sulfide) with 40% glass fiber. The following is a detailed analysis of its material properties:

First, high temperature resistance

PPS plus glass fiber 40 material has excellent high temperature resistance, its melting point is as high as 281~284 ℃, the heat distortion temperature also reaches 270 ℃.

This material can be used for a long time under the high temperature environment of 200 ~ 240 ℃ without easy damage, so it is suitable for a variety of high-temperature working environment.

Second, mechanical properties

Due to the addition of 40% glass fiber, PPS plus glass fiber 40 material excels in strength and stiffness.

It can withstand a variety of complex environmental loads and vibration, with excellent impact resistance, flex resistance and fatigue resistance.

Third, chemical corrosion resistance

PPS resin itself has good acid and alkali resistance.

The addition of glass fiber further improves the chemical resistance of the material, so that it can remain stable in the harsh chemical environment.

Fourth, electrical properties

PPS plus glass fiber 40 material has excellent electrical properties, especially electrical insulation properties.

Its resistivity is higher than other common engineering plastics, suitable for applications that require materials with reliable insulation properties.

Five, dimensional stability

PPS with glass fiber 40 material has excellent dimensional stability, can maintain stable size and shape in a variety of environments.

Six, other properties

PPS plus glass fiber 40 material also has good flame retardancy, up to UL94V-0 grade, with self-extinguishing.

At high temperatures, it can still maintain good electrical properties, and good fluidity, easy to mold, molding almost no shrinkage convex spot.

In summary, PPS plus glass fiber 40 material with its excellent high temperature resistance, mechanical properties, chemical resistance, electrical properties and dimensional stability and other characteristics, in many industrial applications occupy an important position. It is suitable for automotive, electronics, aerospace and other fields, especially in the application scenarios that require high strength, high stiffness and high temperature resistance performance is outstanding.

What is the shrinkage of pps plus fiberglass 40 material?

The shrinkage of PPS plus fiberglass 40 (i.e., PPS plus 40% glass fibers) materials is generally between 0.3% and 0.7%, but there may be cases where the shrinkage is as small as 0.15% to 0.25%. This range of shrinkage allows the material to maintain a high degree of dimensional stability during the injection molding process, making it ideal for the manufacture of precision parts.

Please note that the shrinkage of PPS plus Glass Fiber 40 materials is affected by a variety of factors, including processing, mold design, and environmental conditions. During the injection molding process, process parameters such as temperature, pressure, and cooling rate can have a significant impact on the shrinkage of the material. In addition, the design of the mold will also affect the shrinkage of the material. Reasonable mold design can help to reduce internal stresses, which in turn reduces the shrinkage rate. At the same time, changes in temperature and humidity in the processing environment may also have an impact on the shrinkage of the material, therefore, the need to maintain stable environmental conditions in the production process.

Overall, PPS plus glass fiber 40 material has excellent overall properties, including flame retardancy, high temperature resistance, thermal stability, corrosion resistance, chemical resistance, and low creep, which makes it widely used in a variety of fields. When selecting and using this material, it is recommended to fully consider its shrinkage characteristics as well as the influencing factors mentioned above to ensure the quality and performance of the final product.

What happens to PPS plus fiberglass 40 materials in a humid environment?

PPS plus fiberglass 40 (i.e., PPS plus 40% glass fiber) materials in a humid environment will maintain a certain degree of performance stability, but may also be affected by a certain degree of specific performance as follows:

First, to maintain performance stability

Low hygroscopicity: PPS material itself is characterized by low hygroscopicity, which means that it does not easily absorb moisture. Therefore, in a humid environment, PPS plus fiberglass 40 material can maintain a relatively stable performance, not like some other materials as a result of water absorption and lead to dimensional changes or performance degradation.

II. Possible Effects

Risk of long-term exposure: Although PPS plus fiberglass 40 materials have low hygroscopicity, they may still absorb a certain amount of water if they are exposed to extremely humid environments for a long period of time. This may lead to slight changes in some of the material's properties, such as a decrease in electrical properties or a slight reduction in mechanical strength.

Effects during processing: During processing, if the ambient humidity is too high, this may lead to bubbles or surface defects in the material during injection molding. Therefore, when processing PPS plus glass fiber 40 materials in a humid environment, special attention needs to be paid to the control of environmental humidity and dry processing of raw materials.

Third, countermeasures

Drying treatment: dry the PPS plus glass fiber 40 raw materials before processing to reduce its moisture content. This helps to prevent a variety of problems caused by moisture during processing.

Control of environmental humidity: in the processing process to maintain a relatively stable environmental humidity, to avoid excessive high or low humidity on the material properties have a negative impact.

Use moisture-proof packaging: use moisture-proof packaging materials during storage and transportation to protect PPS plus glass fiber 40 materials from the effects of humid environments.

In summary, although PPS with fiberglass 40 materials can maintain a certain degree of performance stability in humid environments, it is still necessary to take appropriate measures to prevent it from being affected by excessive humidity.

Related Keywords

Related Keywords