Pomalux ® SD-A (Static-dissipative Acetal Copolymer)

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 100 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

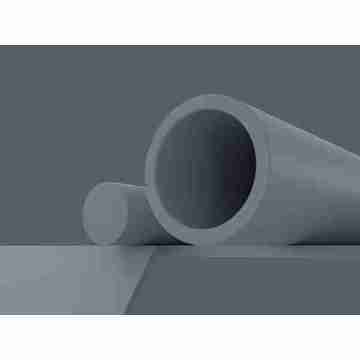

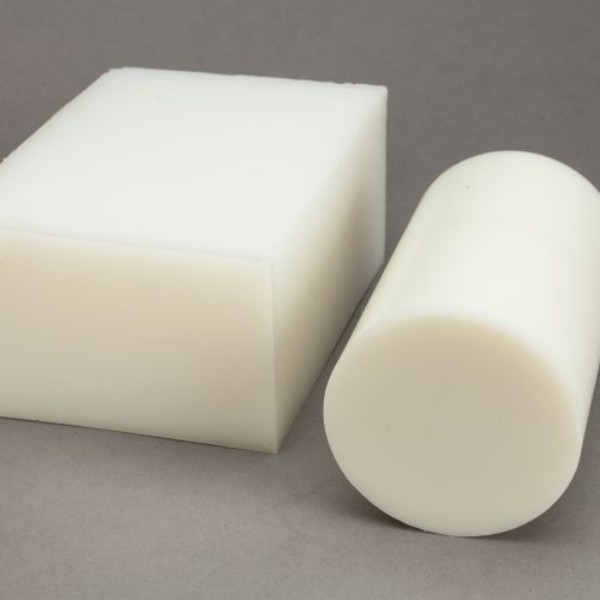

Pomalux® Family

Pomalux® SD-A

Pomalux® POMC SD-A (Anti Static polyoxymethylene copolymer) is a permanently antistatic acetal copolymer. Surface resistivity in the 10ee9 to 10ee11 ohm/sq independent of humidity and temperature is typical. Natural/off white in color, this material offers enhanced lubricity, superior wear resistance, and ease of machining. Exhibiting low outgassing and non-sloughing characteristics, Pomalux® POMC SD-A is optimal for applications where sloughing cannot be accepted.

Pomalux® SD-A is a non-carbon-filled, permanently static dissipative material which is non-migratory and non-humidity dependent. With enhanced lubricity, Pomalux SD-A provides superior wear resistance and ease of machining. Its extremely low outgassing values and non-sloughing characteristics make it ideal for applications where particulate generation cannot be tolerated. Enhanced lubricity, chemically resistant, and dimensionally stable.

Key Properties

Consistent Resistivity Values

Ease of Machining

Low Outgassing

Applications

Automotive Equipment

Disk Drive Assembly Fixtures

Semiconductor/Electronic Components

Telecommunication Hardware

Typical Properties of Pomalux ® SD-A (Static-dissipative Acetal Copolymer)

| DETAIL | |||

| Description | Value | ||

| Material Type | Semi-Crystalline Thermoplastic | ||

| Chemical Name | POM Polyoxymethylene Acetal Copolymer | ||

| Trade Name | Pomalux®SD-A | ||

| Additives | Non Carbon SD Additive | ||

| Color | Natural (Beige) | ||

| Manufacturer | Westlake | ||

| PHYSICAL | |||

| Property | Test | Unit of Measure | Value |

| Density | ASTM D792 | g/cm³ | 1.3 |

| ASTM D792 | lb/in³ | 0.047 | |

| Water Absorption, 24 hrs, Immersion | ASTM D570 | % by wt. | 2.5 |

| MECHANICAL | |||

| Property | Test | Unit of Measure | Value |

| Tensile Strength | ASTM D638 | psi | 6,200 |

| Flexural Strength | ASTM D790 | psi | 8,600 |

| Flexural Modulus | ASTM D790 | psi | 260,000 |

| Hardness | NA | Shore D76 | |

| IZOD Impact-Notched | ASTM D256 | ft-lb/in | 2 |

| THERMAL | |||

| Property | Test | Unit of Measure | Value |

| Coefficient of Linear Thermal Expansion | ASTM D696 | x 10-5 in./in./℉ | 6.5 |

| Heat Deflection Temp | ASTM D648 | ℃ at 264 psi | 89 |

| ASTM D648 | ℉ at 264 psi | 192 | |

| Max Continuous Operating Temp | ℃ | 82 | |

| ℉ | 180 | ||

| Minimum Operating Temp | ℃ | -50 | |

| ℉ | -58 | ||

| Thermal Conductivity | ASTM C117 | BTU-in/ft³-hr-℉ | 2.1 |

| Flammability Rating | UL94 | NA | HB |

| ELECTRICAL | |||

| Property | Test | Unit of Measure | Value |

| Surface Resistivity | ASTM D257 | ohm/square | 10^8 - 10^10 |

Related Keywords

Related Keywords