Black White Acetal Plastic POM Sheet

-

$3.901-99 Kilogram

-

$3.80100-999 Kilogram

-

$3.70≥1000 Kilogram

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | Enough |

|---|---|

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Guangzhou,Hongkong |

HONY®Acetal sheet rod 10-100mm black acetal sheet, POM is a kind of dystectic, high crystallinity thermoplastic engineering plastic material, its mechanical property is very close to metal material, can be used in 100°C normally.POM sheet can be applied to making components and parts of mechanical equipment, such as wheel gear, bearing, pump case, which is widely employed in the field of auto industry, electronics, medical devices, packing services, food machinery. There are POM-C and POM-H in the market, and POM-C has the most market share, because it is easy to compound and machine, and our company can both offer POM-C and POM-H sheet.

What is Acetal Sheet?

Acetal Sheet is one of the best engineering plastics for machining. The main reasons is that it chips as it is being machine rather than creating that long swarf thread that can often wrap round the cutter as with some other engineering plastics. We’d recommend the use of very sharp cutting as tools and to get that super finish, a tool that is shaped similar to a smoothing tool would allow Acetal Sheet to be machined to a very smooth finish and leave fewer machining marks. The result is you get a high quality finish with little further input required. This means that Acetal Sheet can sometimes work out more economical merely by the fact that it can be machined much faster with less operator input. We also reckon it’s better because Acetal leaves almost no post machining burrs, a great advantage when you consider the time consuming act of manually de-burring intricate parts by hand.

Is Acetal Sheet suitable for CNC Machines?

Acetal Sheet is an outstanding choice for use on high speed CNC automated machines. It means you can clamp the sheet down, set the machine going and let it machine, drill, bore or tap with little further to do.

Feature

High abrasion resistance

Low coefficient of friction

High heat resistance

Good electrical and dielectric properties

Low water absorption

Polyoxymethylene POM Sheet Applications

Mechanical gears, sliding and guiding elements, housing parts, springs, chains, screws, nuts, fan wheels, pump parts, valve bodies.

Electrical Engineering:insulators, bobbins, connectors, parts for electronic devices such as televisions, telephones, etc.

Vehicle: Fuel sender unit, Light stock (including shifter for light, turn signal), power windows, door lock systems, articulated shells.

Model: Model Railway parts, such as bogies and handle bars. POM tougher than ABS, in bright translucent colors, and not paintable.

Packaging: aerosol cans, vehicle tanks.

Construction: Structural Glass - pod holder for point.

|

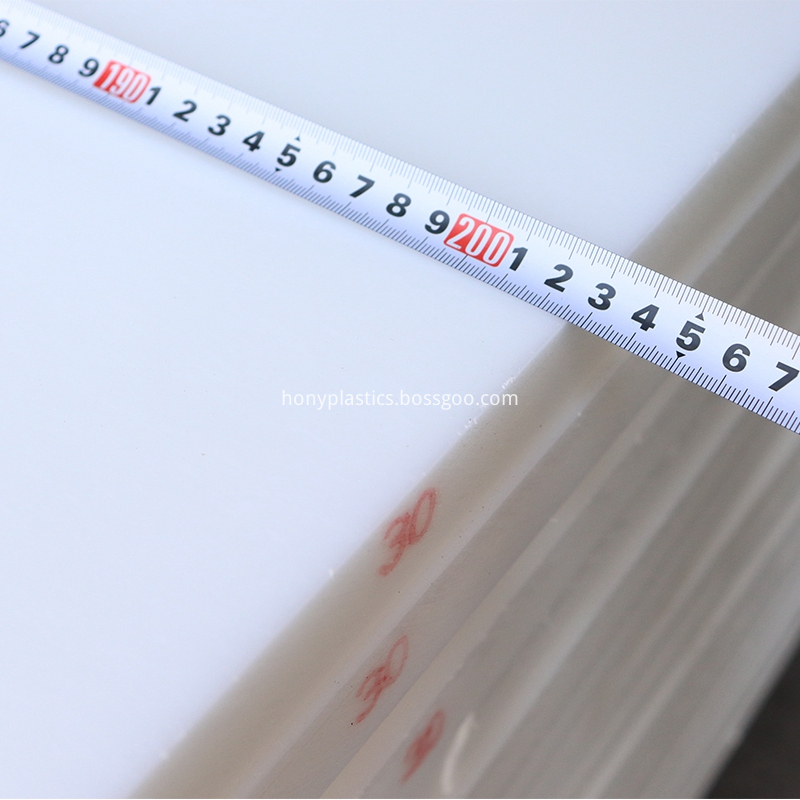

HONY®POM Acetal Delrin sheet size |

|

| Thickness(mm) | Width x Length (mm) |

| 0.3-1.5mm(in roil) | W: 700mm , any length |

| 2-5mm | 620 x 1200mm |

| 6-12mm | 620 x 1200mm |

| 16-60mm | 1000 x 2000mm , 1220 x 2440mm |

| 65-200mm | 620 x 1200mm, 1000 x 2000mm |

| HONYPOM Acetal Delrin rod size | |

| Diameter(mm) | Length(mm) |

| 2-5mm(in roil) | Any length |

| 6-100mm | 1000mm , 3000mm |

| 110-250mm | 1000mm |

| HONY POM Technical Data Sheet |

|

|

|

| Property item | Testing method | Unit | Testing data |

|

Mechanical properties |

|||

| Density | ASTM D792 | g/cm3 | 1.43 |

|

Tensile strength at yield |

ASTM D638 | Mpa | 60 |

|

Elongation at break |

ASTM D638 | % | 30 |

|

Bending strength |

ASTM 790 | Mpa | 100 |

|

Flexural modulus |

ASTM 790 | Mpa | 2800 |

|

Shore Hardness |

ASTM D2240 | D | 85 |

|

Impact strength |

ASTM D256 | J/M | 74 |

|

Thermal performance |

|||

|

Melting point |

DSC | ℃ | 165 |

|

Heat distortion temperature |

ASTM D648 | ℃ | 130 |

|

Long-term working temperature |

- | ℃ | 100 |

|

Short-term working temperature |

- | ℃ | 150 |

|

Thermal conductivity |

DIN 52612-1 | W/(K-M) | 0.31 |

|

Coefficient of linear expansion |

ASTM D696 | 10-5-1/K | 13 |

|

Electrical properties |

|||

|

Dielectric strength |

ASTM D150 | KV-mm | 19 |

|

Dielectric loss coefficient |

ASTM D150 | - | 0.007 |

|

Volume resistance |

ASTM D257 | Ω.cm |

1014 |

|

Surface resistance |

ASTM D257 | Ω |

1016 |

|

Dielectric constant |

ASTM D149 | - | 3.7 |

|

Chemical properties |

|||

|

Balanced water absorption |

23℃ 60%RH | % | 0.22 |

|

Acid resistance |

23℃ 60%RH |

|

+ |

|

Alkali resistance |

|

|

+ |

|

Acid and alkali water resistance |

|

|

+ |

|

Chloric acid and alkali resistance |

|

|

0 |

|

Resistant to aromatic compounds |

|

|

+ |

|

Copper resistance |

23℃ 60%RH |

|

+ |

|

Hot water resistance |

23℃ 60%RH |

|

+ |

|

Other properties |

|||

|

Combustibility |

UL 94 |

|

HB |

|

Stickiness |

|

|

+ |

|

toxic free and safe |

EEC 90/128 FDA |

|

+ |

|

Coefficient of friction |

DIN 53375 |

|

0.35 |

|

anti-UV |

- |

|

0 |

Remark:

1."+" Tolerable , “-”Intolerable , "0" Depends on the situation

2. The above data is obtained from raw material test data, which is not completely consistent with the performance of the finished product, and the uniqueness of the data is not guaranteed

Main product

Related Keywords