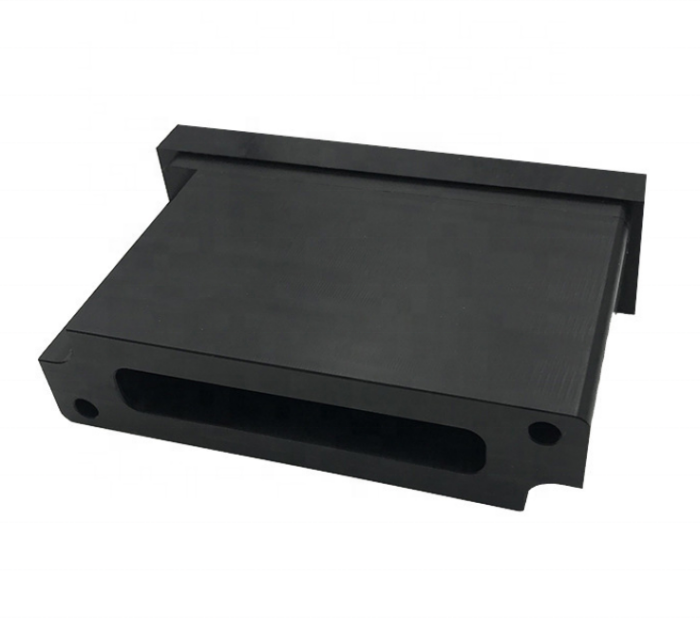

3/4/5 Axis POM CNC Machining parts

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

How much accuracy can be achieved in pom machining

0.015mm

The machining accuracy of POM material can reach 0.015 mm. POM (Polyoxymethylene) is a high-density, high crystallinity linear polymer with good mechanical and chemical properties, especially excellent friction resistance. In turning processing, POM material can reach an accuracy of 0.015 millimeters.

Factors affecting the machining accuracy of POM

Thermal influence: POM material has poor heat resistance, turning will produce a lot of heat, although the cutting fluid can provide some help, but the tool wear is still obvious.

Material properties: POM is divided into homopolymer and copolymer, homopolymer has high density, high crystallinity and high melting point, but poor thermal stability; copolymer has low density, low crystallinity and low melting point, but better thermal stability.

Machining methods: POM parts can be accurately machined by controlling the feed and increasing the speed. In addition, the use of high-performance tools such as diamond-coated tools, triangular ceramic grooving tools also help to improve machining accuracy.

Specific methods to improve the machining accuracy of POM

Pre-treatment: Soak the POM material in water for more than 48 hours, then rough it up, reserving an amount of 1-2 millimeters. Then boil it in 100 degree water for about one hour, or put it directly inside the oven to bake, and then use frozen sucker to do percolation cold clamping.

Choose the right tool: choose white steel knife for precision machining, the freezing disk can release the heat of machining, so as to ensure the flatness within 1-2 silk.

Related Keywords

Related Keywords