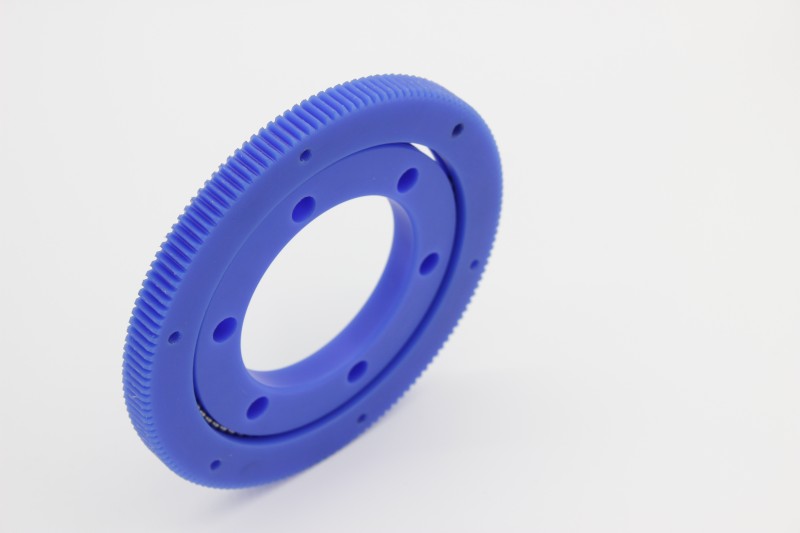

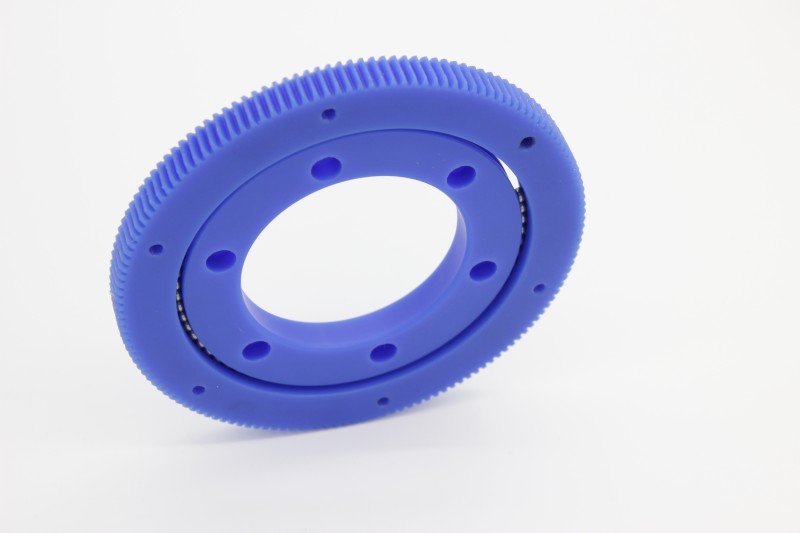

Plastic bearing with external gear

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | Export package |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

What are plastic bearings?

Plastic bearings are a kind of bearings made of plastic material as the main component, usually can be divided into two categories: plastic rolling bearings and plastic plain bearings. The main difference between the two lies in the working principle: the friction that occurs when plastic rolling bearings work is rolling friction, while the plastic sliding bearings work is sliding friction.

First, about plastic plain bearings, it has some significant features and advantages:

1. Overall lubricating material:

The whole plastic bearing is made of lubricating material, which makes its service life relatively long.

2. Corrosion and rust resistance:

Plastic bearings will not rust in use, and have good corrosion resistance, especially for chemical fluids and other environments, while metal bearings in these environments are prone to rust.

3. Lightweight design:

The quality of plastic bearings is lighter than metal, which is more suitable for the modern trend of lightweight design.

4. Low manufacturing cost:

The manufacturing cost of plastic bearings is lower than that of metal, and they are processed by injection molding, which is very suitable for mass production.

5. Low noise and vibration absorption:

Plastic bearings in operation almost no noise, and has a certain vibration-absorbing function, which makes it more quiet and smooth in the application.

6. High and low temperature working performance:

Plastic plain bearings are suitable for working in high and low temperature environment of -200~+250 degrees.

Second, the application range of plastic bearings:

It covers a wide range of fields from fitness equipment to office equipment and automobile industry. For example, in automobile manufacturing, plastic bearings are mainly used in automobile engines, transmission systems, suspension systems and other parts, which can improve the performance of the car and fuel economy. In home appliance manufacturing, plastic bearings are used in the motor part of washing machines, electric fans, air conditioners and other household appliances to reduce wear and noise and extend service life.

In addition, POM plastic bearings and PP plastic bearings are suitable for making more precise plastic bearings due to their good mechanical strength and wear resistance, and they can work in the temperature range of -60℃ to 100℃.

In summary, plastic bearings play an increasingly important role in the modern industrial field with its unique advantages and wide application prospects.

Plastic Bearing Types

There are two main types of plastic bearings: plastic rolling bearings and plastic plain bearings.

The difference between plastic rolling bearings and plastic plain bearings:

Plastic rolling bearings and plastic plain bearings working principle can be distinguished by the name, plastic rolling bearings work when the friction is rolling friction, and plastic sliding bearings work when the sliding friction; rolling friction of the size of the main depends on the manufacturing precision; and plastic sliding bearing friction of the size of the main depends on the bearing sliding surface of the material.

Plastic bearing material common type:

1, Acetal bearing material: this material is the lowest price, it is on the steel dynamic, static friction factor are extremely low, strength and stiffness is also high, commonly used to manufacture light load under the even outer ring overall bearing seat;

2, Nylon bearing material: is a cheap and low friction factor of the material, self-lubricating strong, often add graphite, molybdenum disulfide and PTFE fillers to increase self-lubrication, strength and stiffness, the working temperature up to 120 ℃;

3, Polytetrafluoroethylene bearing materials: friction factor is the smallest, and when the load increases, the friction factor decreases accordingly, often add glass fiber, graphite, bronze powder, etc. in order to improve the performance indicators, the working temperature is relatively high;

4, Phenolic bearing materials: high strength, high temperature resistance, but the friction factor is larger, faster wear, with PTFE resin as filler, can reduce the friction factor and improve life.

Related Keywords

Related Keywords