Ertalyte® PET-P Machining Service

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 100 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

Ertalyte® is an unreinforced, semi-crystalline thermoplastic polyester manufactured by Quadrant EPP. Based on polyethylene terephthalate (PET-P), Ertalyte® exhibits excellent dimensional stability, excellent wear resistance, low efficient of friction, high strength, and resistance to some acidic solutions. Its melting point is almost 150°F above acetal and it retains more of its original strength at higher temperatures than nylon or acetal. Ertalyte® has a continuous service temperature of 210°F. It is non-staining, has low water absorption and is FDA, USDA, and 3A-Dairy compliant. Ertalyte® is easy to machine.

Ertalyte® is a family of unreinforced, semi-crystalline thermoplastic polyester based on polyethylene terephthalate (PET) products. The specific properties of virgin crystalline PET make it especially suitable for the manufacture of mechanical precision parts must endure high loads and wear conditions. It is characterized as having excellent dimensional stability coupled with excellent wear resistance, a low coefficient of friction, high strength, and resistance to moderately acidic solutions. Ertalyte®'s continuous service temperature is 210°F (100°C) and its melting point is almost 150°F higher than acetals. It retains significantly more of its original strength up to 180°F (85°C) than nylon or acetal. For food-grade PET, Ertalyte® grades are excellent candidates for parts used in the food processing and equipment industries.

Ertalyte® is an ideal material for precision parts used in high load, high wear applications in the industrial and food processing industries.

Ertalyte® Key Properties

Ertalyte®'s properties make it especially suitable for the manufacture of precision mechanical parts which are capable of sustaining high loads and enduring wear conditions. Ertalyte® TX is an internally lubricated thermoplastic polyester providing enhanced wear and inertness over general purpose nylon(PA) and acetal (POM) products. Containing uniformly dispersed solid lubricant, Ertalyte® TX provides a lower wear rate and coefficient of friction than unmodified polyesters like PET or PBT and even internally lubricated materials like Delrin® AF blend. Both Ertalyte® natural and black, and Ertalyte TX are FDA compliant. Natural Ertalyte® is also USDA, 3A-Dairy and Canada AG compliant.

Good for Both Wet and Dry Environments

High Strength and Rigidity

Ideal for Close Tolerance Parts

FDA Compliant

Excellent Stain Resistance

Good Wear Resistance

Excellent Dimensional Stability

Better Acid Resistance than Nylon or Acetal

TX Grade Offers Lower COF & Better Wear Properties

Common Ertalyte® Applications

Bushings & Bearings

Can & Bottle Filling Bushings

Food & Beverage Components

Manifolds

Pharmaceutical Carousels

Pharmaceutical Filter Tracks

Pharmaceutical Locating Disks

Pharmaceutical Rings

Pharmaceutical Test Equipment

Piston & Fill Valves for Food Processing

Process and Test Equipment Manifolds

Pump & Valve Components

Rollers

Structural Components

Thrust Washers

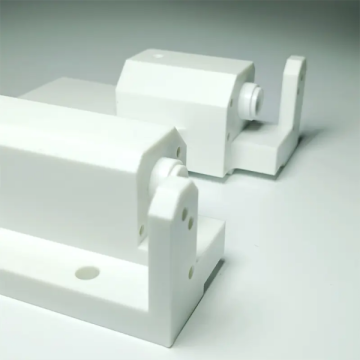

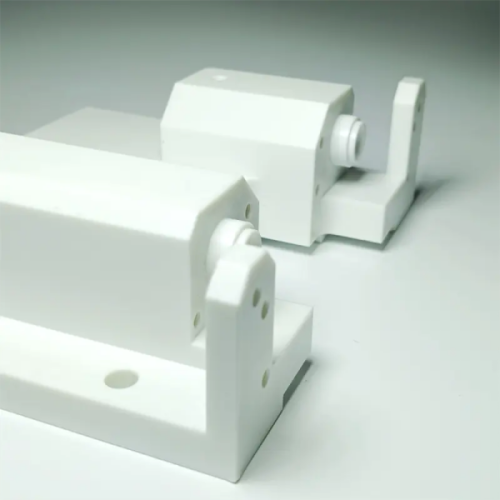

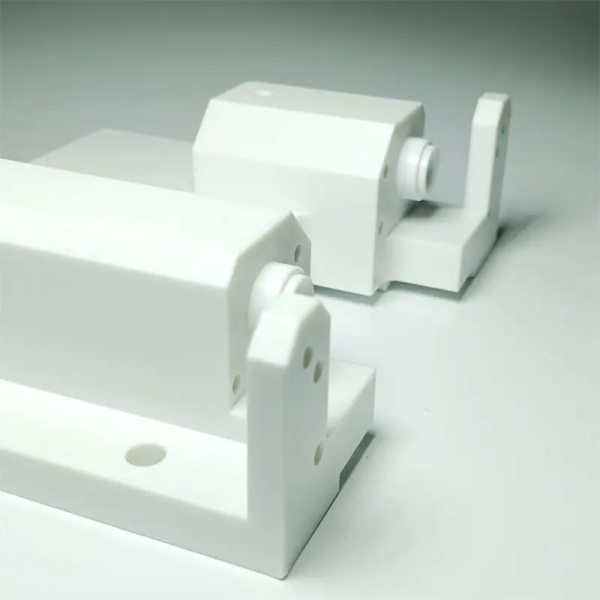

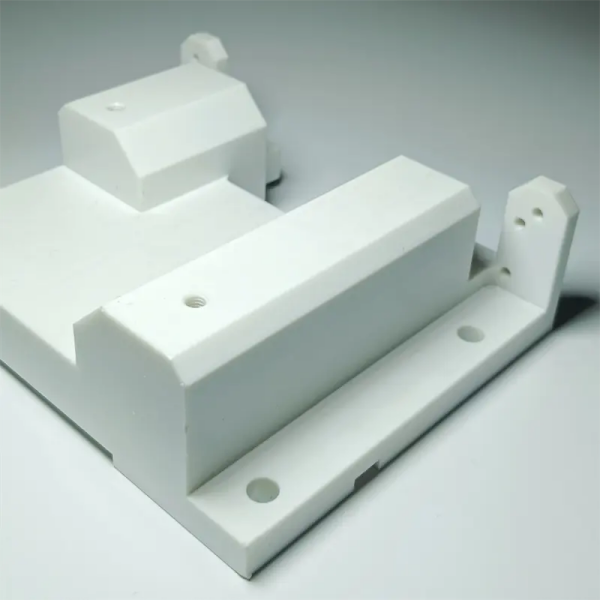

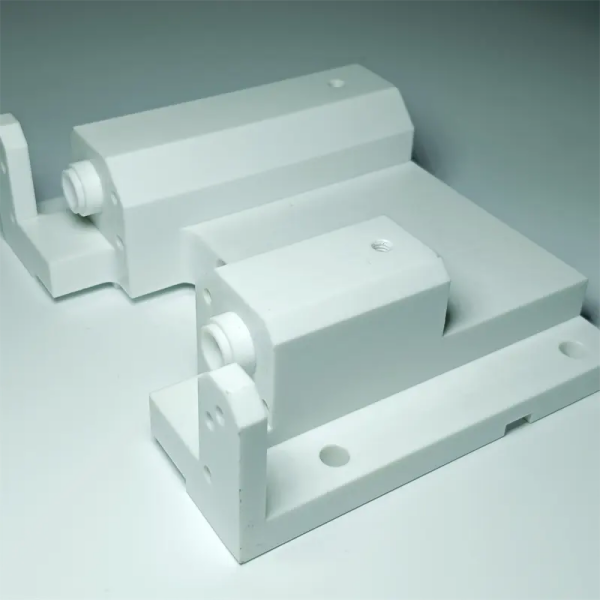

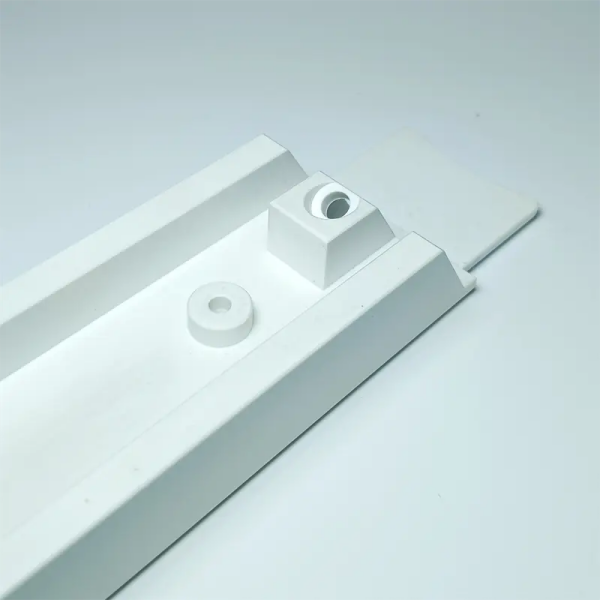

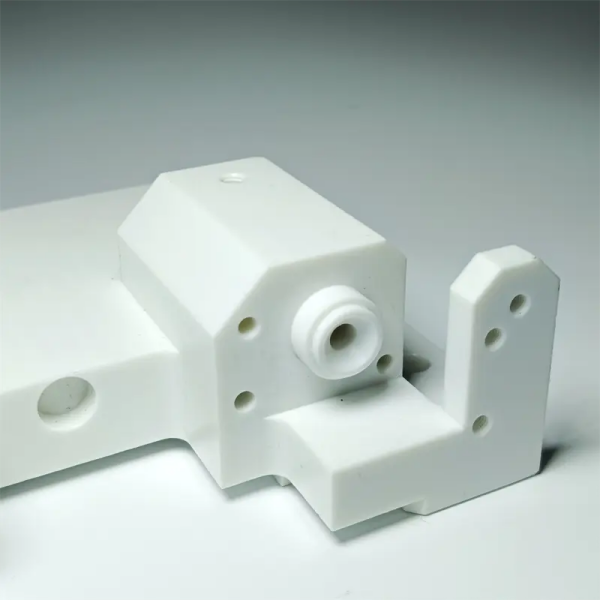

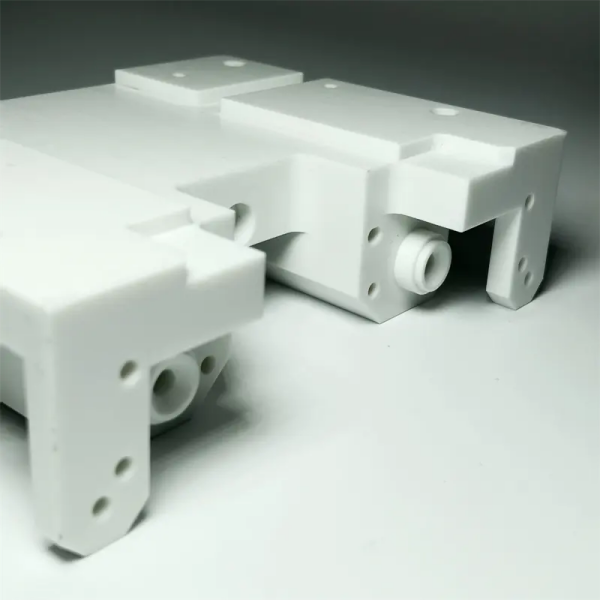

HONY Plastic provide Ertalyte® Machining Services

Engineering, including CAD/CAM, product and tooling design

Assistance with material selection

Complete precision fabricating and CNC machining services, including, CNC milling, drilling, and CNC turning

Precision tolerances to +/-0.005”

Sizes from small, intricate parts up to large parts

Quantities from prototypes through full production runs

In-process quality inspections and testing of finished parts prior to delivery

Certifications to meet industry standards, including MIL specs, AMS standards, or RoHs compliance

Related Keywords

Related Keywords