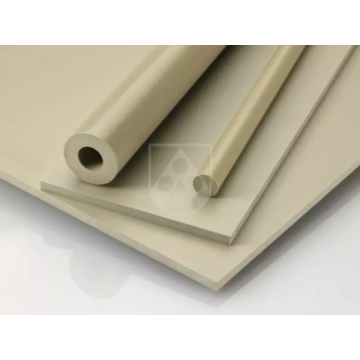

TECAPEEK RP natural Stock Shapes

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 100 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

TECAPEEK RP natural is comparable to the fossil based version and is characterised by outstanding mechanical properties, especially at high temperatures. The reprocessed PEEK material is also known for its chemical resistance and application temperatures of up to 260 °C. Thanks to its excellent dimensional stability and high creep resistance, it is particularly suitable for demanding machined parts.

Ensinger engages in PEEK reprocessing of TECAPEEK RP natural in the form of PEEK tubes, PEEK plates and PEEK rods made from reprocessed plastic material.

TECAPEEK RP natural is part of Ensinger's "Reuse for Tomorrow" solutions, which includes carefully developed products that contribute significantly to environmental protection through their reduced CO2 footprint.

FACTS

Chemical designation

PEEK (Polyetheretherketone)

Colour

beige

Density

1.31 g/cm3

MAIN FEATURES

from reprocessed by-products/ production residues with optimized PCF

inherent flame retardant

good heat deflection temperature

good machinability

resistance against high energy radiation

very good chemical resistance

high creep resistance

hydrolysis and superheated steam resistant

TARGET INDUSTRIES

chemical technology

mechanical engineering

electronics

energy industry

food technology

oil and gas industry

aircraft and aerospace technology

automotive industry

semiconductor technology

vacuum technology

Techanical Data Sheet

| Mechanical properties | ||||

| MECHANICAL PROPERTIES | VALUE | UNIT | PARAMETER | NORM |

| Modulus of elasticity | 4200 | MPa | 1mm/min | DIN EN ISO 527-2 |

| (tensile test) | ||||

| Tensile strength | 109 | MPa | 50mm/min | DIN EN ISO 527-2 |

| Tensile strength at yield | 109 | MPa | 50mm/min | DIN EN ISO 527-2 |

| Elongation at yield (tensile test) | 5 | % | 50mm/min | DIN EN ISO 527-2 |

| Elongation at break (tensile test) | 15 | % | 50mm/min | DIN EN ISO 527-2 |

| Flexural strength | 175 | MPa | 2mm/min, 10 N | DIN EN ISO 178 |

| Modulus of elasticity | 4200 | MPa | 2mm/min, 10 N | DIN EN ISO 178 |

| (flexural test) | ||||

| Compression modulus | 3400 | MPa | 5mm/min, 10 N | EN ISO 604 |

| Compression strength | 23/43/102 | MPa | 1% / 2% / 5% | EN ISO 604 |

| Impact strength (Charpy) | n.b. | kJ/m2 | max. 7,5J | DIN EN ISO 179-1eU |

| Notched impact strength (Charpy) | 4 | kJ/m2 | max. 7,5J | DIN EN ISO 179-1eA |

| Shore hardness | 89 | D | DIN EN ISO 868 | |

| Thermal properties | ||||

| THERMAL PROPERTIES | VALUE | UNIT | PARAMETER | NORM |

| Glass transition temperature | 150 | C | DIN EN ISO 11357 | |

| Melting temperature | 341 | C | DIN EN ISO 11357 | |

| Heat distortion temperature | 162 | C | HDT, Method A | ISO-R 75 Method A |

| Thermal conductivity | 0.27 | W/(k*m) | ISO 22007-4:2008 | |

| Specific heat | 1.1 | J/(g*K) | ISO 22007-4:2008 | |

| Service temperature | 300 | C | short term | NN |

| Service temperature | 260 | C | long term | - |

| Thermal expansion (CLTE) | 5 | 10-5*1/K | 23-60°C, long. | DIN EN ISO 11359-1;2 |

| Thermal expansion (CLTE) | 5 | 10-5*1/K | 23-100°C, long. | DIN EN ISO 11359-1;2 |

| Thermal expansion (CLTE) | 7 | 10-5*1/K | 100-150°C, long. | DIN EN ISO 11359-1;2 |

| Electrical properties | ||||

| ELECTRICAL PROPERTIES | VALUE | UNIT | PARAMETER | NORM |

| surface resistivity | 1015 | Ω | Silver electrode, 23°C, 12% r.h. | - |

| volume resistivity | 1015 | Ω*cm | Silver electrode, 23°C, 12% r.h. | DIN IEC 60093 |

| Dielectric strength | 73 | kV/mm | 23°C, 50% r.h. | ISO 60243-1 |

| Resistance to tracking (CTI) | 125 | V | Platin electrode, 23°C, 50% r.h., solvent A | DIN EN 60112 |

| Other properties | ||||

| OTHER PROPERTIES | VALUE | UNIT | PARAMETER | NORM |

| Resistance to hot water/ bases | + | - | ||

| Flammability (UL94) | V0 | listed (value at 1.5mm) | DIN IEC 60695-11-10; | |

| Resistance to weathering | - | - | ||

| Water absorption | 0.02 - 0.03 | % | 24h / 96h (23°C) | DIN EN ISO 62 |

| Water absorption | % | saturation (23°C) | DIN EN ISO 62 | |

Related Keywords