TECAPEEK® CM XP109 BLACK PEEK Compound

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

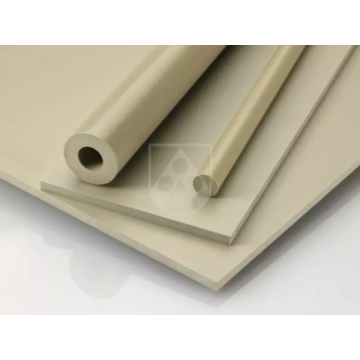

TECAPEEK CM XP109 black PEEK MOD. 30% CARBON FIBRE AND 15% PTFE

This compression moulded material is a Victrex® PEEK polymer modified with 30% carbon fibre and 15% PTFE for improved sliding and wear properties, and increased strength.

FACTS

Chemical designation

PEEK (Polyetheretherketone)

Colour

black

Density

1.51 g/cm3

MAIN FEATURES

inherent flame retardant

good heat deflection temperature

hydrolysis and superheated steam resistant

good machinability

good slide and wear properties

TARGET INDUSTRIES

oil and gas industry

| PEEK Compound: 30% carbon fiber with 15% PTFE | ||||

| Properties | ASTM | Units | Typical Values | |

| Test Method | ||||

| Mechanical | Tensile Strength | D-638 | psi | 11,800 |

| Tensile Elongation | D-638 | % @ Yield | 1.3 | |

| Tensile Elongation | D-638 | % @ Break | 1.8 | |

| Tensile Modulus | D-638 | psi | 1,520,000 | |

| Flexural Strength | D-790 | psi | 15,500 | |

| Flexural Modulus | D-790 | psi | 1,500,000 | |

| Flexural Strain | D-790 | % | - | |

| Compressive Strength (1%) | D-695 | psi | 7,700 | |

| Compressive Strength (10%) | D-695 | psi | 20,500 | |

| Compressive Modulus | D-695 | psi | 720,000 | |

| Izod Impact Strength (Notched) | D-256 | ft-lb/in | 0.68 | |

| Shear Strength | D-732 | psi | - | |

| Hardness | D-2240 | Shore D | 90 | |

| Hardness | D-785 | Rockwell (M) | - | |

| Thermal | Heat Distortion Temperature | D-648 | ℉ | - |

| Coefficient of Linear | E-831 | 10-6/℉ | - | |

| Thermal Expansion | ||||

| Thermal Conductivity | C-177 | BTU in/hr-ft2-℉ | - | |

| Continuous Use (Mechanical) | UL746B | 。 | - | |

| Limiting Oxygen Index | D-2863 | %O2 | - | |

| Melt Point | DSC | ℉ | 649 | |

| Electrical | Dielectric Strength | D-149 | KVcm | - |

| Dielectric Constant | D-150 | 50Hz, 200℃ | - | |

| Volume Resistivity | D-257 | ohm-cm | - | |

| Surface Resistivity | D-257 | ohm/sq | - | |

| Physical | Specific Gravity | D-792 | gm/cm3 | 1.51 |

| Color | - | - | Black | |

| Filler Content | - | % | 45 | |

| Water Absorption (RT 24h) | D-570 | % | - | |

| Typical Level of Crystallinity | - | % | - | |

| Other | Static Coefficient of Friction | D-1894 | - | - |

| Kinetic Coefficient of Friction | D-1894 | - | - | |

Related Keywords