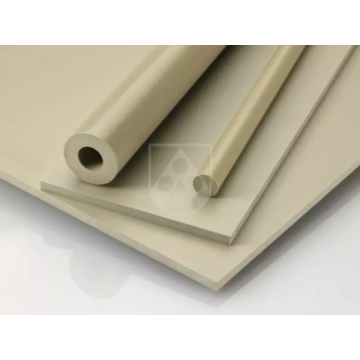

SustaPEEK MOD black sheet

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

The SustaPEEK MOD family of materials is based on polyetheretherketone resin. This semi-crystalline advanced material exhibits a unique combination of high mechanical properties, temperature resistance and excellent chemical resistance making it the most popular advanced plastics material.

The addition of carbon fibres, PTFE and graphite to virgin PEEK results in a SustaPEEK "Bearing Grade".

Key Benefits:

High mechanical load bearing capacity

Superb wear resistance

High pressure velocity (PV) rating

Low friction

Good chemical resistance

Characteristics

Excellent sliding and abrasion behaviour

High rigidity

hardly inflammable

Self-extinguishing

Very low smoke density

very high resistance to high-energy radiation

Low creep tendency

Very high continuous service temperature

Low coefficient of thermal expansion

high dimensional stability under heat

Good wear resistance

Good dimensional stability

ideal combination of tensile strength, stiffness and impact strength

Applications:

Replacement of PTFE because of higher mechanical load bearing capacity

Replacement of metals

Pump components

Valve seats

Bearings

Components exposed to boiling water or steam

Technical Specifications SustaPEEK MOD black

General properties

Test Method

Unit

Guideline Value

Density

DIN EN ISO 1183-1

g / cm3

1,46

Water absorption

DIN EN ISO 62

%

0,2

Flammability (Thickness 3 mm / 6 mm)

UL 94

V0 / V0

Mechanical properties

Test Method

Unit

Guideline Value

Yield stress

DIN EN ISO 527

MPa

75

Elongation at break

DIN EN ISO 527

%

4

Tensile modulus of elasticity

DIN EN ISO 527

MPa

4900

Notched impact strength

DIN EN ISO 179

kJ / m2

5

Shore hardness

DIN EN ISO 868

scale D

85

Thermal properties

Test Method

Unit

Guideline Value

Melting temperature

ISO 11357-3

°C

343

Thermal conductivity

DIN 52612-1

W / (m * K)

0,24

Coefficient of linear thermal expansion

DIN 53752

10-6 / K

30

Service temperature, long term

Average

°C

-30 … 250

Service temperature, short term (max.)

Average

°C

310

Heat deflection temperature

DIN EN ISO 75, Verf. A, HDT

°C

293

Related Keywords