Ketron® CM GF30 PEEK Poly-ether-ether-ketone

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Ketron® GF30 Polyetheretherketone PEEK is a compression molded, 30% glass fiber reinforced grade with excellent dimensional stability and outstanding chemical, corrosion, and creep resistance. With the addition of glass fibers, Ketron® GF30 PEEK has a significantly low expansion rate and high flexural modulus. In addition to these characteristics, Ketron® GF30 PEEK is often favored for structural applications that require improved strength, stiffness, or stability, especially at temperatures above 300°F / 150°C.

Material Properties

Compression molded

Favored for structural applications that require improved strength, stiffness, or stability, especially at temperatures above 300°F / 150°

High flexural modulus

Excellent wear resistance and toughness

Low expansion rate

Abrasion resistant

Outstanding dimensional stability

Available Geometries

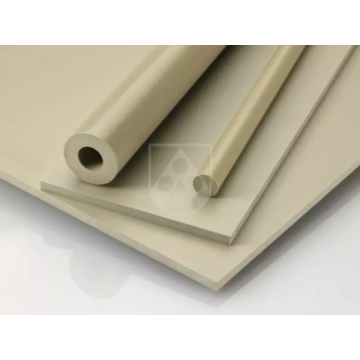

Ketron® CM GF30 PEEK stock shapes encompass a range of standard sizes in the following geometries: Tubular bar, Plate

Available Colors

Ketron® CM GF30 PEEK stock shapes come in the following colors: Natural (beige)

Key Properties

Enhanced Dimensional Stability Over Unfilled PEEK

Higher Strength & Stiffness

Ideal for High Strength High Temp Structural Applications

Compression Molded Grade Offers Larger Shapes & Thicker Cross Sections

Limitations

Poor Chemical Resistance to Halogens and Their Acids Including Bromine, Chlorine, Fluorine, HBr and HF

Applications

Connectors

Electrical Housings

Structural Food Processing Components

Structural Oil & Gas Down Hole Components

Structural Parts

Typical Properties of Ketron ® CM GF30 PEEK

| Description | Value | ||

| Material Type | Semi-Crystalline Thermoplastic | ||

| Chemical Name | PEEK Polyetheretherketone | ||

| Trade Name | Ketron®CM GF30 PEEK | ||

| Additives | 30% Glass | ||

| Color | Black | ||

| Manufacturer | MCAM | ||

| PHYSICAL | |||

| Property | Test | Unit of Measure | Value |

| Density | ASTM D792 | g/cm³ | 1.59 |

| ASTM D792 | lb/in³ | 0.057 | |

| Water Absorption, 24 hrs, Immersion | ASTM D570 | % by wt. | 0.15 |

| Water Absorption, Saturation, Immersion | ASTM D570 | % by wt. | 0.5 |

| MECHANICAL | |||

| Property | Test | Unit of Measure | Value |

| Tensile Strength | ASTM D638 | psi | 7400 |

| Tensile Modulus | ASTM D638 | psi | 850000 |

| Tensile Elongation at Break | ASTM D638 | % | 1 |

| Flexural Strength | ASTM D790 | psi | 12000 |

| Flexural Modulus | ASTM D790 | psi | 900000 |

| Compressive Strength | ASTM D695 | psi | 19000 |

| Compressive Modulus | ASTM D695 | psi | 500000 |

| Hardness | ASTM D785 | NA | Rockwell M103 (R124) |

| IZOD Impact-Notched | ASTM D256 | ft-lb/in | 1 |

| THERMAL | |||

| Property | Test | Unit of Measure | Value |

| Coefficient of Linear Thermal Expansion | ASTM D696 | x 10-5 in./in./°F | 1.4 |

| Heat Deflection Temp | ASTM D648 | °C at 264 psi | 232 |

| ASTM D648 | °F at 264 psi | 450 | |

| Melting Point Temp | ASTM D3418 | °C | 340 |

| ASTM D3418 | °F | 644 | |

| Max Continuous Operating Temp | °C | 249 | |

| °F | 480 | ||

| Minimum Operating Temp | °C | -60 | |

| °F | -76 | ||

| Thermal Conductivity | ASTM C117 | BTU-in/ft²-hr-°F | 3.06 |

| Flammability Rating | UL94 | NA | V-0 |

| ELECTRICAL | |||

| Property | Test | Unit of Measure | Value |

| Dielectric Strength | ASTM D149 | V/mil | 550 |

| Surface Resistivity | ASTM D257 | ohm/square | >10^13 |

Related Keywords