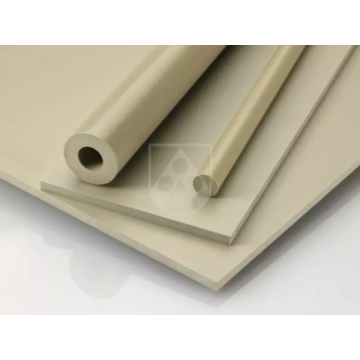

Ceramic filled PEEK TECAPEEK CMF grey

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

TECAPEEK CMF grey is a composite material based on Victrex® PEEK 450G polymer, that is filled with ceramic and grey pigment. TECAPEEK CMF grey is a colour alternative with the same properties as TECAPEEK CMF white, thus, is suitable for applications where the white colour can cause reflections that distort optical systems, or for applications where grey colour is visually preferred.

The TECAPEEK CMF series has been designed with ceramic fillers to offer the highest level of dimensional stability and micro machinability of tight tolerances, which are key properties needed for machining fine features of IC test sockets and electronic fixtures.

The ceramic filler system allows for high accuracy and precise dimensions of microstructures by resisting burr formation and deformations during machining, as well as minimising moisture absorption. Reducing the necessity of secondary deburring operations lowers fabrication costs. The right level of stiffness and elongations allows machinability of micro holes smaller than 0,1 mm with high hole position accuracy.

Elevated level of rigidity also enables one to resist bending of parts with thin cross sections. TECAPEEK CMF grey retains the outstanding characteristics of PEEK natural such as high temperature resistance (260 °C), low thermal expansion, low moisture uptake, and excellent strength.

Compared to fibre-reinforced plastics, ceramic filled peek offers reduced drill bit deflection, enabling higher hole position accuracy. Reduced drill bit wearing compared to fibre-reinforced plastics result in longer drill bit lifetime, impacting machining costs. Compared to injection molded plates, TECAPEEK CMF is produced via an extrusion molding technology resulting in less residual stresses, warpage, and bending during machining. Low internal stress and warpage is crucial for realising the stringent flatness tolerances of contact plates with thin cross sections. Moreover, lower internal stress enables faster speeds and feeds during machining, resulting in faster part production and better yield, which reduces fabrication cost and time.

TECAPEEK CMF grey is included in Ensinger's semiconductor grade portfolio, that is produced with stringent contamination controls and offering copy exact compliance. In this way, Ensinger ensures the highest level of cleanliness and quality performance consistency of this unique property profile. With TECAPEEK SD black, Ensinger also offers a ESD version with comparable properties for enhanced micro machinability.

As with all Ensinger semiconductor grade materials, we can confirm that TECAPEEK CMF grey meets the limitations imposed by RoHS Directive 2011/65/EU Restriction of Hazardous Substances in electrical equipment, and can also provide further conformity declarations on request.

FACTS

Chemical designation

PEEK (Polyetheretherketone)

Colour

grey

Alternative colours available

white

Density

1.65 g/cm3

MAIN FEATURES

good machinability

high strength

high stiffness

low thermal expansion

low burring

good heat deflection temperature

very good thermal stability

TARGET INDUSTRIES

semiconductor technology

mechanical engineering

vacuum technology

electronics

Technical Data Sheet

Modulus of elasticity

5500

MPa

1mm/min

DIN EN ISO 527-2

(tensile test)

Tensile strength

105

MPa

50mm/min

DIN EN ISO 527-2

Tensile strength at yield

102

MPa

50mm/min

DIN EN ISO 527-2

Elongation at yield (tensile test)

4

%

50mm/min

DIN EN ISO 527-2

Elongation at break (tensile test)

5

%

50mm/min

DIN EN ISO 527-2

Flexural strength

170

MPa

2mm/min, 10 N

DIN EN ISO 178

Modulus of elasticity

5500

MPa

2mm/min, 10 N

DIN EN ISO 178

(flexural test)

Compression modulus

4300

MPa

5mm/min, 10 N

EN ISO 604

Impact strength (Charpy)

35

kJ/m2

max. 7,5J

DIN EN ISO 179-1eU

Ball indentation hardness

286

MPa

ISO 2039-1

Compression strength

25/46/105

MPa

1% / 2% / 5%

EN ISO 604

Glass transition temperature

151

C

DIN EN ISO 11357

Melting temperature

339

C

DIN EN ISO 11357

Thermal conductivity

0.38

W/(k*m)

ISO 22007-4:2008

Specific heat

1

J/(g*K)

ISO 22007-4:2008

Service temperature

300

C

short term

NN

Service temperature

260

C

long term

NN

Thermal expansion (CLTE)

5

10-5*1/K

23-60°C, long.

DIN EN ISO 11359-1;2

Thermal expansion (CLTE)

5

10-5*1/K

23-100°C, long.

DIN EN ISO 11359-1;2

Thermal expansion (CLTE)

6

10-5*1/K

100-150°C, long.

DIN EN ISO 11359-1;2

surface resistivity

1014

Ω

-

volume resistivity

1014

Ω*cm

Resistance to hot water/ bases

+

-

-

Flammability (UL94)

V0

-

corresponding to

DIN IEC 60695-11-10;

Resistance to weathering

-

-

-

Water absorption

0.02 - 0.03

%

24h / 96h (23°C)

DIN EN ISO 62

Related Keywords