TECAPEEK ® PVX PEEK bearing grade

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

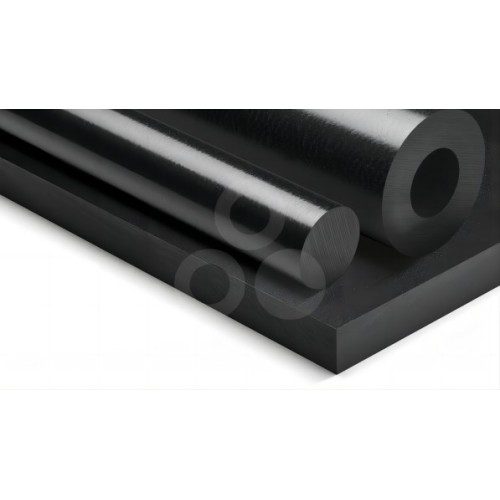

TECAPEEK PVX black is a modified PEEK material using Victrex® PEEK 450 or Solvay KetaSpire® KT-820 and is classified in the same performance category as Victrex® PEEK™ FC30.

TECAPEEK PVX black was developed especially for bearing and sliding applications. It is based on a PEEK polymer that has been modified with 10% each of PTFE, graphite and carbon fibres. It combines the properties of a high-grade matrix material with special, wear-improving additives. Compared to all PEEK modifications, TECAPEEK PVX black has the lowest coefficient of friction, and shows higher wear resistance. In addition, a comparatively higher dimensional stability under thermal load is achieved. The reinforcement by means of carbon fibre and graphite in low friction PEEK plastic also ensures higher mechanical properties than is normally seen with unfilled PEEK.

Furthermore, it is helpful for a PEEK bearing material to have improved thermal conductivity in order to dissipate the frictional heat generated on the component as much as possible, thus avoiding thermal overload or overheating. In particular, the carbon fibre and graphite fillers in TECAPEEK PVX black help ensure improved thermal conductivity of this PEEK bearing grade. It also results in thermal conductivity that is three times higher than what we find in standard PEEK natural.

For bearing and sliding applications, the resistance to high PV loads is particularly remarkable.

A comparison between TECAPEEK natural (unfilled PEEK) and TECAPEEK PVX black (PEEK bearing) also shows the differences relative to the coefficient of friction, depending on the number of cycles and different sliding speeds. The tests were carried out on a steel shaft Ø 4mm, at sliding speeds of 0-22 mm/s and a load of 30 N.

PEEK PVX also offers outstanding tribological performance properties when used with non-metallic mating partners. At the same time, excellent chemical resistance is maintained. It can be used dry or with the application of an external lubricant.

This PEEK bearing modification, TECAPEEK PVX black, was developed for use under high loads and speeds in harsh environments and can also be operated under continuous exposure to hot water or steam.

As with all Ensinger PEEK materials, we can confirm that our bearing grade TECAPEEK PVX black meets the limitations imposed by RoHS Directive 2011/65/EU Restriction of Hazardous Substances in electrical and electronic equipment.

FACTS

Chemical designation

PEEK (Polyetheretherketone)

Colour

black

Density

1.44 g/cm3

MAIN FEATURES

good heat deflection temperature

good slide and wear properties

high creep resistance

hydrolysis and superheated steam resistant

good wear properties

inherent flame retardant

very good chemical resistance

TARGET INDUSTRIES

mechanical engineering

chemical technology

energy industry

automotive industry

aircraft and aerospace technology

Typical Properties of TECAPEEK ® PVX

DETAIL

Description

Value

Material Type

Semi-Crystalline Thermoplastic

Chemical Name

PEEK Polyetheretherketone

Trade Name

TECAPEEK庐 PVX

Additives

Lubricated

Color

Black

Manufacturer

Ensinger

PHYSICAL

Property

Test

Unit of Measure

Value

Density

ASTM D792

g/cm³

1.46

ASTM D792

lb/in³

0.053

Water Absorption, 24 hrs, Immersion

ASTM D570

% by wt.

0.02

Water Absorption, Saturation, Immersion

ASTM D570

% by wt.

0.03

MECHANICAL

Property

Test

Unit of Measure

Value

Tensile Strength

ASTM D638

psi

11000

Tensile Modulus

ASTM D638

psi

800000

Tensile Elongation at Break

ASTM D638

%

2.5

Flexural Strength

ASTM D790

psi

18000

Flexural Modulus

ASTM D790

psi

700000

Compressive Strength

ASTM D695

psi

16500

Compressive Modulus

ASTM D695

psi

330000

Hardness

ASTM D785

NA

Rockwell M95

IZOD Impact-Notched

ASTM D256

ft-lb/in

0.9

Static Coefficient of Friction

NA

0.18

Dynamic Coefficient of Friction

Dynamic, 40 PSI, 50 FPM

NA

0.2

Limiting PV

psi-fpm

500000

THERMAL

Property

Test

Unit of Measure

Value

Coefficient of Linear Thermal Expansion

ASTM D696

x 10-5 in./in./℉

3.11

Heat Deflection Temp

ASTM D648

℃ at 264 psi

277

ASTM D648

℉ at 264 psi

530

Melting Point Temp

ASTM D3418

℃

334

ASTM D3418

℉

633

Max Continuous Operating Temp

℃

260

℉

500

Minimum Operating Temp

℃

-60

℉

-76

Thermal Conductivity

ASTM C117

BTU-in/ft²-hr-℉

5.69

Flammability Rating

UL94

NA

V-0

ELECTRICAL

Property

Test

Unit of Measure

Value

Surface Resistivity

ASTM D257

ohm/square

10^5

COMPLIANCE

Description

Value

FDA

No

USDA

No

NSF

No

3-A Dairy

No

Canadian Food Inspection Agency

No

USP Class VI

No

OTHER

Description

Value

ASTM Shape Spec

D6262 S-PAEK0140R30

UV Resistant

Yes

Machinability

7

Related Keywords