PEEK Film (Polyetheretherketone) Film sold

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CIF,CFR,EXW,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

PEEK film offers an outstanding range of physical, thermal, chemical & radiological properties. PEEK is a high performance semi-crystalline thermoplastic. PEEK's characteristics include high temperature performance, excellent wear properties, superior chemical resistance, hydrolytic stability and outstanding toughness and strength. PEEK meets many aerospace, automotive, fire, smoke and toxicity, food/water, medical/pharmaceutical, and military approvals and standards.

Size

Thicknesses between 10µm (0,01 mm) up to 1000µm (1 mm);

Width usually about 420mm, but customer preferences of special sizes or thicknesses will be provided.

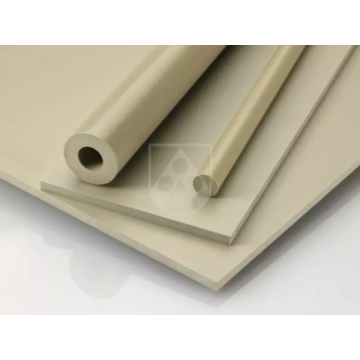

Thin film critical characteristics HONYPLAS®PEEK Sheet Rod

* Mechanical properties: A plastic film that has both toughness and rigidity and is balanced, and has extremely excellent fatigue resistance, which is comparable to alloy materials.

* High temperature resistance: It can withstand the temperature of lead-free soldering process. The RTI grade for non-impact mechanical applications is 220°C, and for electrical applications is 200°C. The carbonization point remains stable up to 500°C.

* Self-lubricating property: It has outstanding sliding properties and is suitable for applications that strictly require low friction coefficient and wear resistance, especially the PEEK film modified by mixing carbon fiber and graphite in a certain proportion has better self-lubricating performance.

* Chemical resistance (corrosion resistance): It has excellent chemical resistance. Among common chemicals, only concentrated sulfuric acid can dissolve or destroy it. Its corrosion resistance is similar to that of nickel steel.

* Flame retardant: very stable polymer, can reach high flame retardant standard without adding any flame retardant, halogen-free, in line with IEC 61249-2-21 standard.

* Stripping resistance: It has good stripping resistance, can be made into a thinly covered electromagnetic wire, and can be used under harsh conditions.

* Fatigue resistance: Excellent fatigue resistance.

* Radiation resistance: the ability to withstand high radiation is very strong, and it can still maintain good insulation ability under ultra-high radiation dose.

* Hydrolysis resistance: not affected by water and high-pressure water vapor, products made of this film material can still maintain excellent characteristics in continuous use in high-temperature and high-pressure water.

* Melt processability: fusion with metal when the temperature is above the melting point, easy ultrasonic sealing (PET film can also be sealed), laser can be melted and printed.

* High sound clarity: avoid the "hearing fatigue" caused by the noise of the metal film, and achieve better acoustic performance.

* Environmental protection and safety: lightweight, recyclable, compliant with RoHS standards, can be used to manufacture products that meet the requirements of the same directive, and meet the requirements of the US Food and Drug Administration (FDA).

* Wide range of thickness options: films with a thickness of 4~300μm can be produced, and can be customized according to customer needs.

Polyetheretherketone (PEEK) Sheet SPECIFICATION

|

产品名称 Product |

颜色 Color |

表面纹理 Texture |

厚度Thickness(μm) |

宽度Width(mm) |

|

PEEK膜 |

棕黄色 Yellowish brown |

光面/光面 Polished/Polished 光面/哑光 Polished/matte 哑光/哑光 matte/matte |

4~100 |

≤650 |

|

100~300 |

≤1060 |

Polyetheretherketone bar TYPICAL PROPERTY VALUES

-

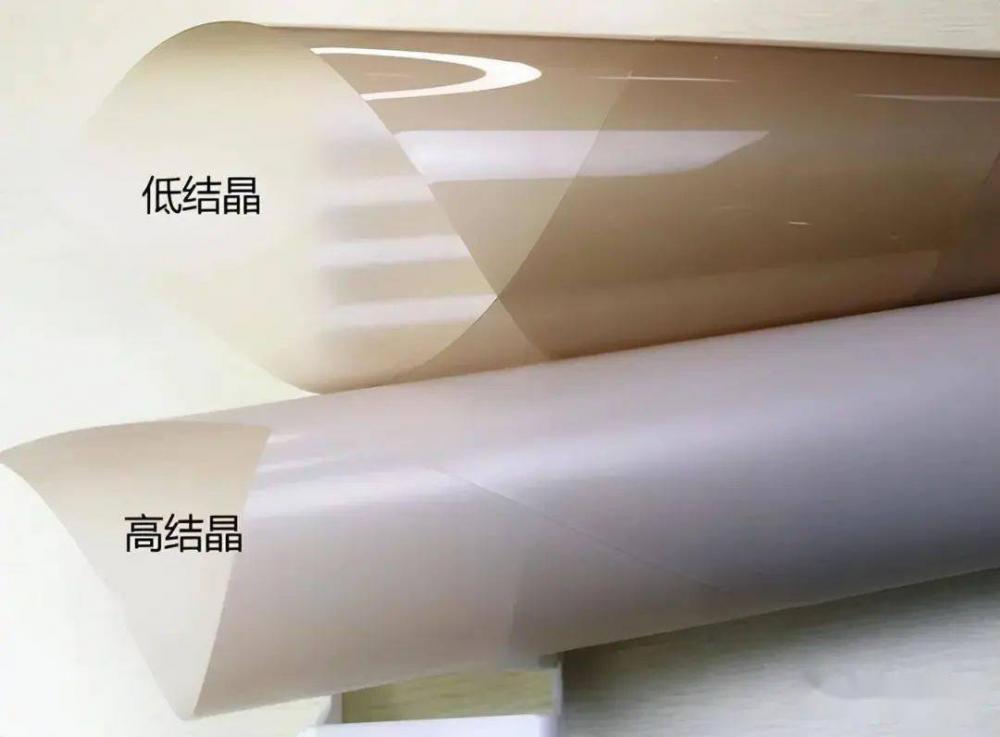

Technical Data Sheet of Amorphous PEEK Film:

|

|

特性 Properties |

测试方法 Test Method |

单位 Units |

测试值Value |

|

物理性能 Physical Performance |

密 度 Density |

ASTM D792 |

g/cm3 |

1.26 |

|

吸水率 Moisture Absorption, 24h |

ASTM D570 |

% |

0.04 |

|

|

热收缩率 Thermal Shrinking Rate |

ISO 11501(200℃) |

% |

<8 |

|

|

机械性能 Mechanical Performance |

拉伸强度 Tensile Strength |

ASTM D882 |

MD(MPa) |

>70 |

|

ASTM D882 |

TD(MPa) |

>70 |

||

|

断裂伸长率 Elongation at Break |

ASTM D882 |

MD % |

>150 |

|

|

ASTM D882 |

TD % |

>150 |

||

|

拉伸弹性模量 Tensile Modulus |

ASTM D882 |

MD % |

>3000 |

|

|

ASTM D882 |

TD % |

>3000 |

||

|

耐温性能 Thermal Performance |

熔 点 Melting Point |

ISO 11357 |

℃ |

343 |

|

热膨胀系数 Coefficient of Thermal Expansion |

ISO 11359(<Tg) |

ppm/K |

40 |

|

|

玻璃化温度 Glass Transition Temperature(Tg) |

ISO 11357 |

℃ |

151 |

|

|

热变形温度 Distortion Temperature |

ASTM D648(0.45MPa) |

℃ |

205 |

|

|

电气性能 Electrical properties |

介电强度 Dielectric Strength(25μm) |

ASTM D149 |

KV/mm |

120 |

|

体积电阻 Volume Resistivity@25℃,50%RH |

ASTM D257 |

Ω·cm |

1016 |

|

|

介电常数 Dielectric Constant(Dk) |

ASTM D150(@23℃,3GHz) |

|

3.2 |

|

|

介电损耗因子 Dielectric Dissipation Factor(Df) |

ASTM D150(@23℃,3GHz) |

|

0.004 |

-

Technical Data Sheet of Semi-crystalline PEEK Film:

|

|

特性 Properties |

测试方法 Test Method |

单位 Units |

测试值Value |

|

物理性能 Physical Performance |

密 度 Density |

ASTM D792 |

g/cm3 |

1.30 |

|

吸水率 Moisture Absorption, 24h |

ASTM D570 |

% |

0.04 |

|

|

热收缩率 Thermal Shrinking Rate |

ISO 11501(200℃) |

% |

<0.5 |

|

|

机械性能 Mechanical Performance |

拉伸强度 Tensile Strength |

ASTM D882 |

MD(MPa) |

>90 |

|

ASTM D882 |

TD(MPa) |

>90 |

||

|

断裂伸长率 Elongation at Break |

ASTM D882 |

MD % |

>120 |

|

|

ASTM D882 |

TD % |

>120 |

||

|

拉伸弹性模量 Tensile Modulus |

ASTM D882 |

MD % |

>3000 |

|

|

ASTM D882 |

TD % |

>3000 |

||

|

耐温性能 Thermal Performance |

熔 点 Melting Point |

ISO 11357 |

℃ |

343 |

|

热膨胀系数 Coefficient of Thermal Expansion |

ISO 11359(<Tg) |

ppm/K |

40 |

|

|

玻璃化温度 Glass Transition Temperature(Tg) |

ISO 11357 |

℃ |

151 |

|

|

热变形温度 Distortion Temperature |

ASTM D648(0.45MPa) |

℃ |

205 |

|

|

电气性能 Electrical properties |

介电强度 Dielectric Strength(25μm) |

ASTM D149 |

KV/mm |

120 |

|

体积电阻 Volume Resistivity@25℃,50%RH |

ASTM D257 |

Ω·cm |

1016 |

|

|

介电常数 Dielectric Constant(Dk) |

ASTM D150(@23℃,3GHz) |

|

3.2 |

|

|

介电损耗因子 Dielectric Dissipation Factor(Df) |

ASTM D150(@23℃,3GHz) |

|

0.004 |

Related Keywords