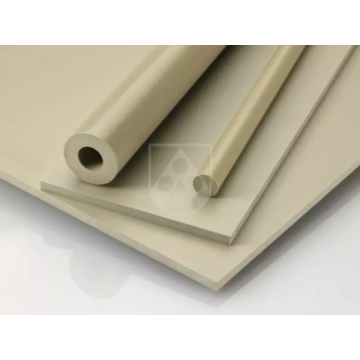

Ketron PEEK 1000 rod round bar

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- SHENZHEN, GUANGZHOU, HONGKONG

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 10000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN,GUANGZHOU,HONGKONG |

Ketron® PEEK 1000 (Virgin, Unfilled PEEK) offers chemical and hydrolysis resistance similar to PPS, but can operate at higher temperatures. Virgin PEEK material offers steam and wear resistance, and can be used continuously to 480°F (250°C) and in hot water or steam without permanent loss in physical properties. For hostile environments, PEEK is a high strength alternative to fluoropolymers. PEEK carries a UL 94 V-O flammability rating and exhibits very low smoke and toxic gas emission when exposed to flame. Ketron® PEEK 1000 is a Virgin, Unfilled PolyetherEtherKetone). This general purpose grade is unreinforced and offers the highest elongation and toughness of all PEEK grades. The newly available black PEEK 1000 is ideal for instrument components where aesthetics are important, as well as for seal components where ductility and inertness are important.

Ketron PEEK 1000 has a very high maximum allowable service temperature in air (250°C continuously, up to 310°C for short periods of time), high mechanical strength, stiffness and creep resistance, also at elevated temperatures, excellent chemical and hydrolysis resistance, excellent wear and frictional behaviour, very good dimensional stability, excellent resistance to high energy radiation (gamma and x-ray), and inherent low flammability and very low levels of smoke evolution during combustion.

Ketron PEEK 1000 is often used to produce structural parts, bushings, bearing, seals, and back up rings.

Ketron PEEK 1000 is available in sheet, rod and tube form and comes in a range of thicknesses.

Features of Polyether Ether Ketone Peek Sheet

Ketron® 1000 PEEK

Peek Natural Color Sheet general purpose grade is unreinforced and offers the highest elongation and toughness of all PEEK grades. Within this group, Ketron® 1000 PEEK black is ideal for instrument components where aesthetics are important, as well as for seal components where ductility and inertness are important

Ketron® PEEK grades offer chemical and hydrolysis resistance similar to PPS, but can operate at higher temperatures. PEEK 1000 offers steam and wear resistance, while carbon-reinforced PEEK provides excellent wear capabilities. Our latest grade, PEEK HPV, offers outstanding bearing performance. PEEK can be used continuously to 480°F (250°C) and in hot water or steam without permanent loss in physical properties. For hostile environments, PEEK is a high strength alternative to fluoropolymers. PEEK carries a V-O flammability rating and exhibits very low smoke and toxic gas emission when exposed to flame.

Ketron® PEEK 1000 (General Purpose)* is unreinforced and offers the highest elongation and toughness of all PEEK grades. The newly available black PEEK 1000 is ideal for instrument components where aesthetics are important, as well as for seal components where ductility and inertness are important.

Ketron® PEEK GF30 Peek Glass Fiber Filled Sheet(30% Glass-Reinforced)* The addition of glass fibers significantly reduces the expansion rate and increases the flexural modulus of PEEK. This grade is ideal for structural applications that require improved strength, stiffness or stability, especially at temperatures above 300°F (150°C).

Ketron® PEEK CA30 (30% Carbon Fiber-Reinforced)* The addition of carbon fibers enhances the compressive strength and stiffness of PEEK, and dramatically lowers its expansion rate. It offers designers optimum wear resistance and load carrying capability in a PEEK-based product. This grade provides more thermal conductivity than unreinforced PEEK — increasing heat dissipation from bearing surfaces improving bearing life and capability.

Ketron® PEEK LSG (Life Science Grade) Family of Products* were developed specifically for Life Sciences applications and are pre-qualified biocompatible materials, helping to save precious time and money. Approved for both the United States Pharmacopeias (USP) and ISO 10993-1 by successfully passing a series of biocompability tests these products are implantable for up to 24 hours with Ketron PEEK CLASSIX up to 30 days. Click on each for more product information.

Related Keywords