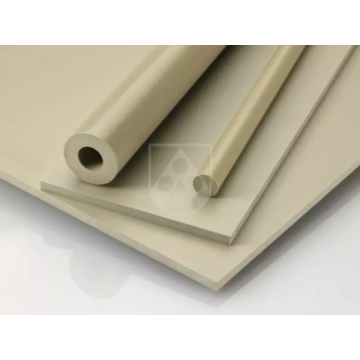

PEEK sheet virgin HONYPLAS brand

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen, Guangzhou, HongKong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | Enough |

|---|---|

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP,DDP |

| Certificate: | SGS RoHS Reach ISO9001 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Guangzhou,HongKong |

HONYPLAS®PEEK Vigin is a kind of high temperature resistant, high performance thermoplastic special engineering plastic. It has good mechanical properties, chemical resistance, abrasion resistance, hydrolysis resistance and other properties; it has a light specific gravity and good self-lubricating performance. Due to its very good processing performance, it can be filled with carbon fiber, molybdenum disulfide, etc. to further improve the lubricating performance and Mechanical strength. The broad application space of PEEK engineering plastics involves aviation, machinery, electronics, chemicals, automobiles and other high-tech industrial fields. It can manufacture high-demand mechanical parts, such as gears, bearings, piston rings, support rings, seal rings (letters), Valve discs, wear rings, etc.

HONYPLAS®PEEK is manufactured may use Victrex® PEEK 450G or ZYPEEK® 550G polymer. Strong, stiff plastic with outstanding chemical resistance; performs over a wide range of temps

The excellent performance of Polyether Ether Ketone Peek Sheet is mainly manifested in the following aspects:

1. High temperature resistance

PEEK has a high glass transition temperature and melting point (334°C), which is one of the reasons why it can be reliably used in applications requiring heat resistance. Its load thermal deformation temperature is as high as 316℃, and its continuous use temperature is 260℃.

2. Mechanical characteristics

PEEK is a plastic with a balance between toughness and rigidity. In particular, its excellent fatigue resistance to alternating stress is the most outstanding among all plastics, comparable to alloy materials.

3. Self-lubricating

PEEK has outstanding sliding properties among all plastics, and is suitable for applications that strictly require low friction coefficient and abrasion resistance. In particular, the self-lubricating performance of PEEK modified with carbon fiber and graphite in a certain proportion is better.

4. Chemical resistance (corrosion resistance)

PEEK has excellent chemical resistance. Among ordinary chemicals, only concentrated sulfuric acid can dissolve or destroy it. Its corrosion resistance is similar to that of nickel steel.

5. Flame retardancy

PEEK is a very stable polymer. Samples with a thickness of 1.45mm can reach the highest flame retardant standards without adding any flame retardants.

6. Peel resistance

PEEK has good peel resistance, so it can be made into thin-covered wires or magnet wires, and can be used under harsh conditions.

7. Fatigue resistance

PEEK has the best fatigue resistance of all resins.

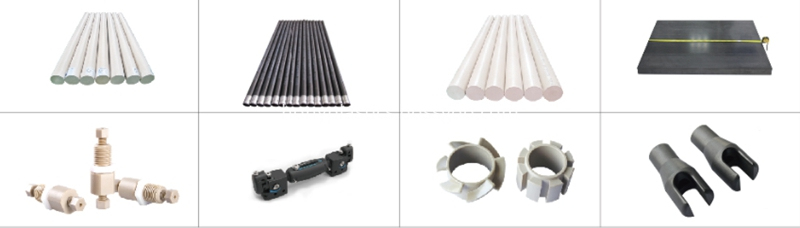

The more mature applications of HONYPLAS®PEEK include: piston ring, thrust ring, choke ring, valve disc, bacteria valve, star wheel, sealing ring, ball valve seat, bearing cage, oil-free lubrication bearing, magnetic pump of air compressor Isolation sleeves, electrodes, gears, screws, magnet wires, radiation shields, microwave digestion tanks, wafer carriers, etc.

HONY Plastic molding processing polyether ether ketone (PEEK) pipes, rods, plates, machining finished parts, injection molding polyether ether ketone (PEEK) products of various specifications, providing polyether ether ketone (PEEK) modified pellets .HONYPLAS®PEEK modified carbon fiber reinforced polyether ether ketone, glass fiber reinforced polyether ether ketone, polytetrafluoroethylene modified polyether ether ketone, graphite, molybdenum disulfide, etc. filled polyether ether ketone, respectively Various molding processes such as molding, injection molding, extrusion, powder spraying, blow molding, rotation, and melt spinning are carried out.

HONYPLAS®PEEK has been widely used in many fields such as petrochemical, electronic and electrical, instrumentation, machinery and automobiles, medical and health, aerospace, military nuclear energy, etc.

HONYPLAS®PEEK grade:

1.HONYPLAS®PEEK Virgin : Brown-gray, made of pure polyether ether ketone resin as raw material, has good toughness and impact resistance among all PEEK grades. Pure PEEK can be sterilized using convenient sterilization methods (steam, dry heat, ethanol and Y-ray), and the raw material composition of PEEK complies with EU and US FDA regulations on food compliance, making it suitable for medical, pharmaceutical and food processing industry.

2.HONYPLAS®PEEK PTFE: Black, the result of adding PTFE, graphite and carbon fiber, makes it a bearing-grade plastic, its superior friction performance (low friction coefficient, wear resistance, higher peak pressure limit) .

3.HONYPLAS®PEEK 30GF Peek Glass Fiber Filled Sheet : Brown-gray, the material is filled with 30% glass fiber reinforced plastic, which has better rigidity and creep resistance than pure PEEK, and better dimensional stability. It is the best choice for manufacturing structural parts. Can withstand a fixed load for a long time at high temperatures

4.HONYPLAS®PEEK 30CF: Black, this material is filled with 30% carbon fiber reinforcement, has better mechanical properties (higher elastic modulus, mechanical strength and creep) and more wear resistance than PEEK 30GF, and carbon fiber reinforced plastic is better than unreinforced plastic PEEK's plastic has 3.5 times the thermal conductivity to dissipate heat from the bearing surface faster

HONYPLAS®PEEK Virgin HONYPLAS®PEEK PTFE HONYPLAS®PEEK 30GF HONYPLAS®PEEK 30CF

HONYPLAS®PEEK Product Technical Properties Data Sheet

| Item | Test standard or instrument | Unit |

PEEK Virgin(100%Virgin) |

PEEK 30CF(30% carbon fiber) | PEEK 30GF(30% glass fiber) |

PEEK PTFE (30%carbon fiber + graphia + PTFE) |

| Mechanical Properties | ||||||

| Tensile strength(23℃) | ISO 527 | MPa | 90 | 210 | 155 | 134 |

| Bending strength(23℃) | ISO 178 | MPa | 163 | 298 | 212 | 186 |

| Compressive strength(23℃) | ISO 604 | Mpa | 118 | 240 | 215 | 150 |

| Lzod impact strength | ISO 180/IU | KJ/m2 | No break | 40 | 51 | 32 |

| Thermal Properties | ||||||

| Melting point | ISO 11357 | ℃ | 343 | 343 | 343 | 343 |

| Distortion temperature | ISO 75-f | ℃ | 163 | 315 | 315 | 293 |

| Continuous using temperature | UL 74685 | ℃ | 260 | 260 | 260 | 260 |

| Coefficient of thermal expansion | ASTM D696 | 10-5℃ | 4.7 | 1.5 | 2.2 | 2.2 |

| Flammable level | UL 94 | V-0@mm | 1.5 | 1.5 | 1.5 | 0.75 |

| Electrical Properties | ||||||

| Dielectric strength | IEC 60243-1 | KV/mm | 18 |

|

19 |

|

| Dielectric constant | IEC 60250 | - | 3.2 |

|

3.3 |

|

| Surface resistivity | IEC 90093 | Ω | 10^15 | 10^5 | 10^15 | 10^6 |

| Other performance | ||||||

| Density | ISO 1183 | g/cm3 | 1.3+-0.02 | 1.4+-0.02 | 1.5+-0.02 | 1.43+-0.02 |

| Rockwell hardness | ISO 2039 | HRR | 118 | 121 | 119 | 108 |

| Friction coefficient | ASTM D3702 | - | 0.30-0.38 | 0.28 | 0.38-0.46 | 0.18 |

| Water absorption (25℃ 24Hrs) | ISO 62 | % | 0.15 | 0.06 | 0.11 | 0.06 |

| Mould shrinking percentage | 3mm 170℃ Flow direction | % | 1.2 | 0.1 | 0.4 | 0.3 |

| Perpendicular to direction | % | 1.5 | 0.5 | 0.8 | 0.5 | |

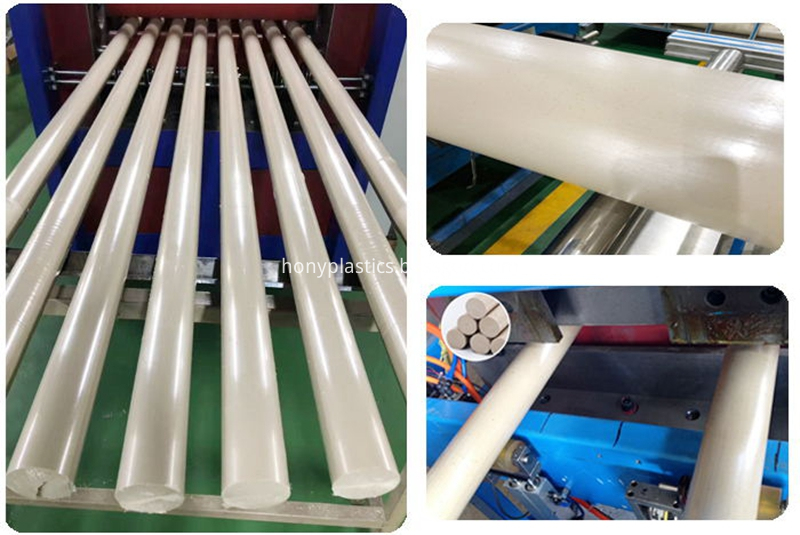

PEEK rods produced by the continuous extrusion process are more suitable for small batches and large-scale products to be produced by machining. PEEK rods with a diameter of 5-250mm can be extruded, and the length is generally 1000 or 2000 or 3000, can also be cut according to customer requirements, there are nearly a hundred kinds of extrusion dies with diameter specifications, and the inventory is complete

HONYPLAS®PEEK Rod Size

| Material | Diameter(mm) | Length(mm) | Color |

| PEEK Virgin | 5-250 | 1000,2000,3000 | Natural,Black |

| PEEK 30CF | 5-250 | 1000,2000,3000 | Natural,Black |

| PEEK 30GF | 5-250 | 1000,2000,3000 | Natural,Black |

| PEEK PTFE | 5-250 | 1000,2000,3000 | Black |

| ESD PEEK | 5-250 | 1000,2000,3000 | Natural |

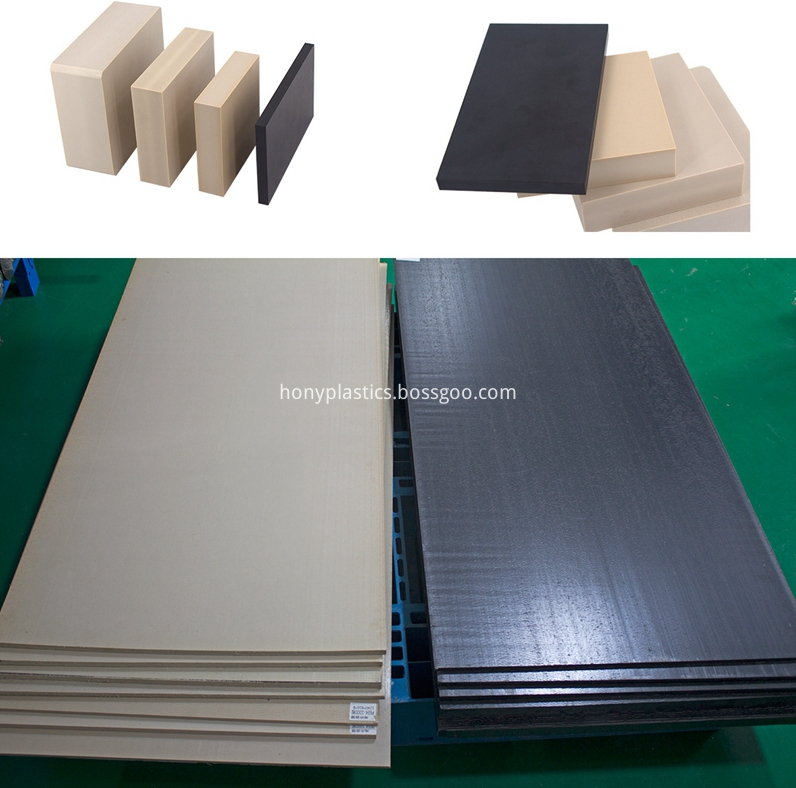

HONY introduced imported PEEK profile extrusion production line to extrude 1250mm wide PEEK sheet to meet the demand of large-size PEEK parts in valve and other industries for ultra-wide PEEK sheet, better improve production efficiency and improve the quality of PEEK products. At the same time, the material utilization rate of the wide plate is very high when the typesetting cutting machine is processed.

HONYPLAS®PEEK Peek Natural Color Sheet Size

| Material | Width(mm) | Thickness(mm) | Length(mm) | Color |

| PEEK Virgin | 600-1250 | 6-60 | 1000,2000,3000 | Natural,Black,Red,Yellow |

| PEEK 30CF | 600-1250 | 6-60 | 1000,2000,3000 | Natural,Black,Red,Yellow |

| PEEK 30GF | 600-1250 | 6-60 | 1000,2000,3000 | Natural,Black,Red,Yellow |

| PEEK PTFE | 600-1250 | 6-60 | 1000,2000,3000 | Natural,Black,Red,Yellow |

| ESD PEEK | 600-1250 | 6-60 | 1000,2000,3000 | Black |

Our partner

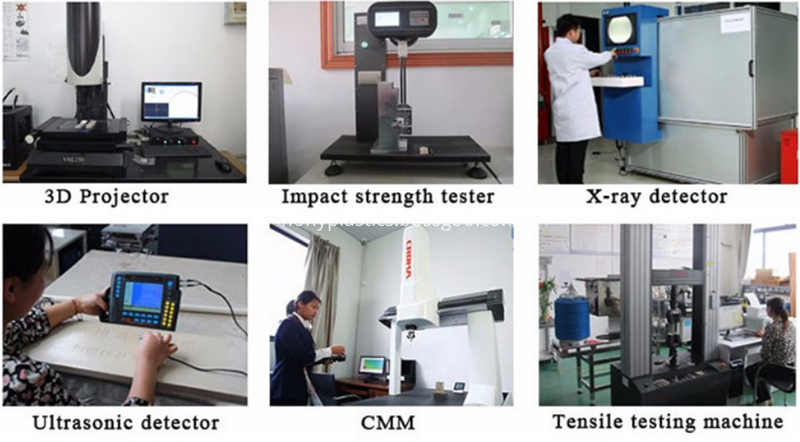

Our Test

Our package

Related Keywords