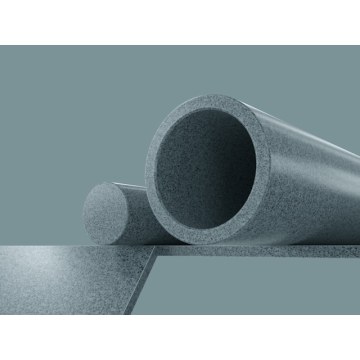

Robalon® FG PE PE-UHMW PE 1000

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Robalon® FG PE — PE-UHMW - PE 1000

Colour white. No molybdenum disulfide alloy, no cross-linking. Physiologically safe. Our plastic complies with the requirements of the EU-regulation 10/2011/EU, which is valid since May 2011, its amendment 1282/2011/EU as well as the framework regulation 1935/2004/EC and the regulation 2023/2006/EC. Of course, our manufacturing processes subject to the philosophy "Good Manufacturing Practice" (2023/2006/EG).

Characteristics

Physiologically safe

Good sliding and wear behaviour

Food compliant according to 10/2011/EU, 1935/2004/EC, FDA

Industries

Drinking & Waste Water Technology

Mechanical Engineering Industry

Food Industry

Agriculture Industry

Alpine Industry

Technical Specifications Robalon® FG

| General properties | |||

| Test Method | Unit | Guideline Value | |

| Density | DIN EN ISO 1183-1 | g / cm3 | 0,93 |

| Water absorption | DIN EN ISO 62 | % | <0,01 |

| Flammability (Thickness 3 mm / 6 mm) | UL 94 | HB/HB | |

| Molecular weight | g/mol | 9,20 * 106 | |

| Color | white | ||

| Mechanical properties | |||

| Test Method | Unit | Guideline Value | |

| Yield stress | DIN EN ISO 527 | MPa | 17 |

| Elongation at break | DIN EN ISO 527 | % | >300 |

| Tensile modulus of elasticity | DIN EN ISO 527 | MPa | 470 |

| Notched impact strength | DIN EN ISO 179/1eA | kJ / m2 | >100 |

| Shore hardness | DIN EN ISO 868 / 15 sec | scale D | 63 |

| Compression - compression set | 23°C, 2N/mm², 1h | % | ∼2 |

| Compression - compression set | 80°C, 10N/mm², 56h | % | ∼20 |

| Thermal properties | |||

| Test Method | Unit | Guideline Value | |

| Melting temperature | DIN EN ISO 3146 | 掳C | 135 |

| Thermal conductivity | DIN EN ISO 8302 | W / (m * K) | 0,41 |

| Thermal capacity | DIN 51005 | kJ / (kg * K) | 1,84 |

| Coefficient of linear thermal expansion | DIN 53752 | 10-6/ K | 200 |

| Service temperature, long term | Average | ℃ | -200 ... 80 |

| Service temperature, short term (max.) | Average | ℃ | 110 |

| Electrical properties | |||

| Test Method | Unit | Guideline Value | |

| Dielectric constant | IEC 60250 | 2,1 ... 3 | |

| Dielectric dissipation factor (106聽Hz) | IEC 60250 | 10 * 10-4 | |

| Dielectric dissipation factor (100 Hz) | IEC 60250 | 3,9 * 10-4 | |

| Volume resistivity | DIN EN 62631-3-1 | Ohm * cm | 1012 |

| Surface resistivity | DIN EN 62631-3-2 | Ohm | 1012 |

| Comparative tracking index | IEC 60112 | 600 | |

| Dielectric strength | IEC 60243 | kV / mm | 45 |

Related Keywords