Pure uhmwpe plastic sheet board

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, HongKong

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 50000 pcs per day |

|---|---|

| Supply Ability: | Enough |

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Certificate: | SGS RoHS Reach ISO9001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,HongKong |

HONY®Wear Resistant UHMWPE 1000 Plastic Sheet is excellent in wear resistance, impact resistance, chemical corrosion resistance, self-lubrication, very low moisture absorption and non-toxicity. Because of its abrasion resistance, chemical resistance and good frictional properties, major application areas of UHMW-PE include bulk material handling, food and beverage machinery; chemical, mining and mineral processing equipment, recreational equipment, transportation and orthopedic implants.Conveyor guide rails, belt scrapers, chain guides, suspension wear plates. These are just a few of the ways UHMW extrusions have been used over the years, with proven long-term results. Extruded UHMW profiles can save up to 50% of the cost of a machined profile.

UHMWPE can be made into gears, cams, impellers, rollers, pulleys, bearings, bearings, bushings, pins, gaskets, seals, flexible couplings, screws and pipe clamp,based on the excellent property of abrasion and impact resistance.These parts are used in textile machinery,paper-making machinery,packaging machinery.

Products range:

UHMWPE Sheet,UHMWPE Board,UHMW-PE Guide rail,UHMW-PE Strips,UHMW-PE Bar ,UHMWPE Panel,UHMWPE Plate,UHMW-PE Pad ,UHMWPE Filter Plate,UHMWPE Fender Pad,HDPE Pad,HDPE Plate,HDPE Panel

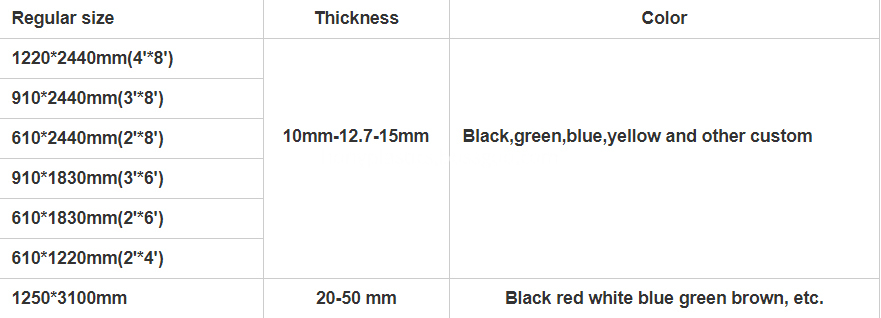

Our standard size :

2000*1000*(6-300) mm 3000*1500*(6-300) mm

3050*1220*(6-300) mm 4500*2000*(6-300) mm

4700*1200*(6-300) mm 5000*1300*(6-300) mm

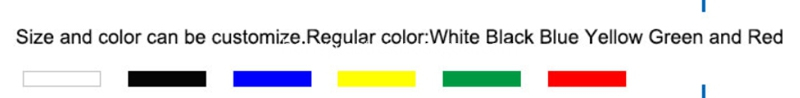

The color of UHMWPE :

Black,Blue,Green,White,Yellow,Red,Orange or other customer color according to your requirements

Our Product type :

UHMWPE 3million molecule weight

UHMWPE 5million molecule weight

UHMWPE 7million molecule weight

UHMWPE 9million molecule weight

High Density Polyethylene

Different shape and size is also available

Characters of UHMWPE sheet

Extremely high anti-abrasion;

Excellent self-lubricating performance;

Good in resisting impact, flexibility;

Being excellent in resisting chemical corrosion(acid, alkali, salt);

Being free from toxin, smell or exudates;

Good electric resistance;

Low in water absorption;

Low coefficient of friction;

Resisting environment and anti-aging;

Resisting high and low temperature;

UV resistance

HONY®UHMWPE Properties Data Sheet

| Property | Test Standard | Unit | PE300 | PE500 | PE1000 |

| Density | ISO1183 | g/cm3 | 0.98 | 0.98 | 0.98 |

| Average Molecular Weight | --- | g/mol | 4.5*10^6 | 7.2*10^6 | 9.2*10^6 |

| Water Absorption | --- | % | <0.01 | <0.01 | <0.01 |

| Tensile Stress F(150/10) | ISO11542-2 | MPA | 0.22+-0.05 | 0.34+-0.07 | 0.51+-0.09 |

| Yield Elongation | ISO291 | % | ≤20 | ≤20 | ≤20 |

| Yield Stress | ISO527 | MPA | ≥17 | ≥17 | ≥17 |

| Elongation at Break | ISO291 | % | >50 | >50 | >50 |

| Tensile Modulus | ISO291 1mm/min | MPA | 570 | 680 | 790 |

| Ball Indentation Hardness | ISO2039 | M/mm2 | 35 | 35 | 35 |

| Shore Hardness D(15s value) | ISO868 | --- | 60 | 60 | 61 |

| Charpy Impact Strength(angle 14) | ISO11542-2 | KJ/m2 | ≥90 | ≥120 | ≥150 |

| Min.Working Temperature | --- | ℃ | -269℃ | -269℃ | -269℃ |

| Heat Deflection Temperature | ISO291 | ℃ | 80℃ | 80℃ | 80℃ |

| Vicat Softening Point | ISO291 | ℃ | 130℃ | 130℃ | 130℃ |

| Melting Point | ISO3146-C | ℃ | 130~135 | 130~135 | 130~135 |

| Linear Thermal Expasion Coefficient(23℃~80℃) | ISO11359 | ℃-1 | 2*10^-4 | 2*10^-4 | 2*10^-4 |

| Thermal Conductivity 23℃ | ISO291 | --- | 0.41 | 0.41 | 0.41 |

| Volume Resistance | ISO291 | Ω.m | >10^12 |

>10^12 |

>10^12 |

| Surface Resistance | ISO291 | Ω | >10^12 | >10^12 | >10^12 |

| Dielectric Strength | ISO291 | KV/mm | 45 | 45 | 45 |

| Dielectric Constant ( under 100Hz 1mhz) | ISO291 | --- | 2.1 | 2.1 | 2.1 |

| --- | 3.0 | 3.0 | 3.0 | ||

| Comparatice Tracking Index(CTI CTIM) | ISO291 | --- | 600 | 600 | 600 |

| --- | 600 | 600 | 600 | ||

| Arc Resistance | ISO291 | Rating | L4 | L4 | L4 |

Color

Main Product

Size

Application

Partner

Related Keywords