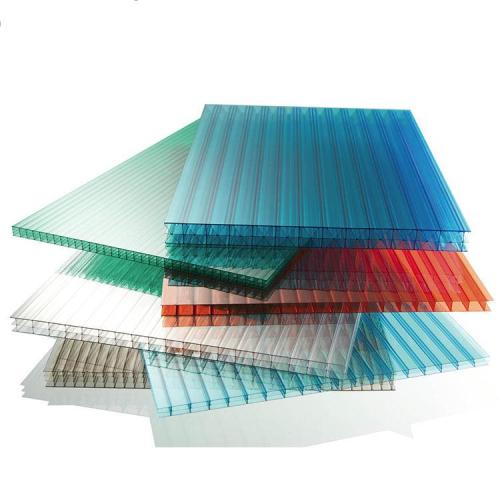

Polycarbonate Panels Roofing Sheets

- Min. Order:

- 1 Kilometer

- Min. Order:

- 1 Kilometer

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Certificate: | ROHS CE REACH |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Polycarbonate sheet (Polycarbonate), also known as PC sheet, is a polymer linear polymer containing carbonate groups in the molecular chain, is the only thermoplastic engineering plastics with good transparency among the five major general engineering plastics.Polycarbonate sheet is actually a very common building material, commonly used in greenhouses, canopies, carports, etc.. Since it can achieve the heat insulation effect that glass cannot, and can be bent into various shapes, it is now also used in the construction of sunrooms.

Polycarbonate panels can be divided into two types according to solid and hollow: solid is usually called endurance panels, usually solid single-layer structure, the conventional thickness from 1.8-20MM, can also be made into wave-type wave panels. Hollow panels are usually called sunlight panels, for multi-layer hollow structure. Sunlight panels are usually used in the roof lighting of the greenhouse of the gymnasium and have a lighter mass. According to the different cross-section, there are many forms, such as honeycomb sunlight panels.

Polycarbonate panels have excellent weather resistance, strength, and good transparency, and have been favored by architects at home and abroad in recent years, and are one of the very ideal lighting materials.

Various materials on the market, only polycarbonate panels (up to 89% light transmission) and acrylic panels can be comparable to the light transmission performance of glass. The acrylic panels, with the use of time, their own materials will change, over time, easy to aging yellowing and breakage, the overall life of the short.

To ensure good long-term performance, polycarbonate panels are molded using ultraviolet coextrusion (UV-coextrusion). During the production process, a high concentration of UV protective film is uniformly melted onto the substrate. This production method avoids several common problems that occur in the production of UV protective films, including adhesion problems and deficiencies in impact damage resistance. When applied to exterior walls, this film also helps buildings better resist environmental effects and aging, ensuring durability in most weather conditions. UV radiation is almost 100% blocked at specific wavelengths (around 380nm). UV coated panels do not yellow and fog when exposed to sunlight bursts. Light transmission loss is only 6% after ten years.

Polycarbonate plate impact strength is 250-300 times that of ordinary glass, 30 times that of the same thickness of acrylic plate, is 2-20 times that of tempered glass, with 3kg hammer below two meters fall also no cracks, there is "unbreakable glass" and "loud steel" reputation. And can be in -40 ℃ -125 ℃ to maintain stability, will not be as easy as glass spontaneous explosion. In some projects, polycarbonate sheets can be seen to achieve similar effects as glass.

Features and Benefits

1. Unique 9-layer X structure

2.UV resistant outer surface

3. Good light transmittance and light diffusion properties

4. Very high stiffness

5. Excellent thermal performance

6. High impact strength

7. Various colors and aesthetic effects

8. Simple, easy and fast installation

Related Keywords