Semitron® CMP XL20 - Wear Resistant PAI

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | CFR,FOB,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Semitron® CMP XL20 was developed from a proprietary polyamide-base resin and offers wear life more than 20 times that of standard PPS in all CMP chemistry environments. This material has the best combination of wear life, and mechanical strength and stiffness, ideal for the most demanding applications and in extreme process environments.

Material Properties

High strength and stiffness promotes fewer edge defects and better uniformity

Good chemical and creep resistance

Excellent wear life

Dimensionally stable

Outperforms PPS up to 20x in most processes

Available Geometries

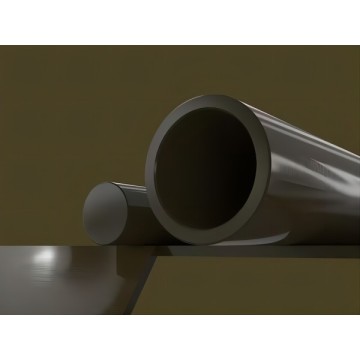

Semitron® CMP XL20 PAI stock shapes encompass a range of standard sizes in the following geometries: Rod, Plate

Available Colors

Semitron® CMP XL20 PAI stock shapes come in the following colors: Green

Key Properties

Significantly lower cost per wafer

Outperforms PPS up to 20x in most processes

High strength and stiffness promotes fewer edge defects and better uniformity

Applications

CMP Retaining Rings

Typical Properties of Semitron ® CMP XL20 PAI

| Description | Value | ||

| Material Type | Imidized Amorphous Thermoplastic | ||

| Chemical Name | PAI Polyamide-imide | ||

| Trade Name | Semitron® CMP XL20 | ||

| Color | Black Green Hue | ||

| Manufacturer | Quadrant | ||

| PHYSICAL | |||

| Property | Test | Unit of Measure | Value |

| Density | ASTM D792 | g/cm³ | 1.41 |

| ASTM D792 | lb/in³ | 0.051 | |

| Water Absorption, 24 hrs, Immersion | ASTM D570 | % by wt. | 0.4 |

| Water Absorption, Saturation, Immersion | ASTM D570 | % by wt. | 1.7 |

| MECHANICAL | |||

| Property | Test | Unit of Measure | Value |

| Tensile Strength | ASTM D638 | psi | 18,000 |

| Tensile Modulus | ASTM D638 | psi | 600,000 |

| Tensile Elongation at Break | % | 10 | |

| Flexural Strength | ASTM D790 | psi | 24,000 |

| Flexural Modulus | ASTM D790 | psi | 600,000 |

| Compressive Strength | ASTM D695 | psi | 24,000 |

| Compressive Modulus | ASTM D695 | psi | 478,000 |

| Hardness | ASTM D785 | NA | Rockwell E80 / M120 |

| IZOD Impact-Notched | ASTM D256 | ft-lb/in | 2 |

| Dynamic Coefficient of Friction | - | NA | 0.35 |

| Wear K Factor | - | in³-min/ft-lbs-hr | 50 |

| Limiting PV | - | psi-fpm | 12,500 |

| THERMAL | |||

| Property | Test | Unit of Measure | Value |

| Coefficient of Linear Thermal Expansion | ASTM D696 | x 10-5 in./in./°F | 1.7 |

| Heat Deflection Temp | ASTM D648 | °C at 264 psi | 278 |

| ASTM D648 | °F at 264 psi | 532 | |

| Max Continuous Operating Temp | °C | 260 | |

| °F | 500 | ||

| Minimum Operating Temp | °C | -200 | |

| °F | -328 | ||

| Thermal Conductivity | ASTM C117 | BTU-in/ft²-hr-°F | 1.8 |

| Flammability Rating | UL94 | NA | V-0 |

| ELECTRICAL | |||

| Property | Test | Unit of Measure | Value |

| Dielectric Strength | ASTM D149 | V/mil | 580 |

| Dielectric Constant at 1 MHz | ASTM D150 | NA | 4.2 |

Related Keywords