Duratron® T7530 30% carbon fiberreinforced polyamideimide

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Land, Ocean, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Transportation: | Land,Ocean,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Duratron® T7530 is a compression molded, 30% carbon fiber-reinforced polyamide-imide with 1-5% PTFE that exhibits outstanding strength and stiffness in non-abrasive wear applications. Duratron® T7530 has the lowest coefficient of linear thermal expansion of all PAI materials, making it an ideal solution for applications that require exceptional dimensional stability and involve extreme temperatures.

Material Properties

Lowest coefficient of thermal expansion of all PAIs

30% carbon fiber-reinforced

Outstanding strength and stiffness in non-abrasive wear applications

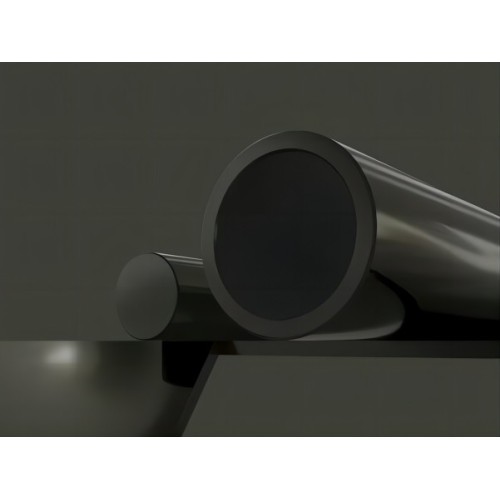

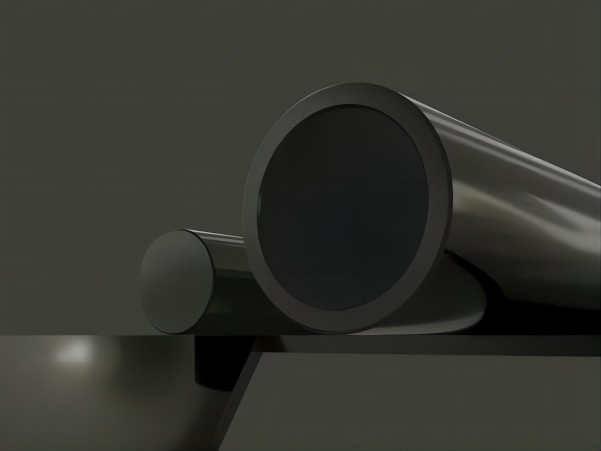

Available Geometries

Duratron® T7530 PAI stock shapes encompass a range of standard sizes in the following geometries: Plate, Tubular bar

Available Colors

Duratron® T7530 PAI stock shapes come in the following colors: Black

Key Properties

Thermal Performance to 500°F (260°C) Continuous Use Temp

Carbon Reinforced Grade

Higher Strength and Modulus

Exceptional Creep Resistance

Good Fatigue Resistance

Excellent Dimensional Stability

Lowest Coefficient of Linear Thermal Expansion CLTE of PAI Grades – Close to Steel

Compression Molded Grade Offers Larger Shapes & Thicker Cross Sections

Limitations

Duratron® T PAI Grade Materials have a relatively high moisture absorption rate, parts used in high temperature service or made to tight tolerances should be kept dry prior to installation.

Thermal shock resulting in deformation can occur if moisture laden parts are rapidly exposed to temperatures above 400°F (205° C).

Chemical Resistance to Strong Bases, Steam and Some High Temperature Acids

Applications

Aerospace Components

Gears

High Strength High Pressure Structural Components

Housings

Impellers

Metal Replacement

Oil & Gas Components

Pistons

Shrouds

Sliding Compressor & Pump Vanes

Typical Properties of Duratron ® T 7530 Carbon Filled PAI Compression Molded

DETAIL

Description

Value

Material Type

Imidized Amorphous Thermoplastic

Chemical Name

PAI Polyamide-imide

Trade Name

Duratron® T7530 PAI

Additives

Carbon Filled

Color

Black

Manufacturer

Mitsubishi Chemical Advanced Materials

PHYSICAL

Property

Test

Unit of Measure

Value

Density

ASTM D792

g/cm³

1.51

ASTM D792

lb/in³

0.055

Water Absorption, 24 hrs, Immersion

ASTM D570

% by wt.

0.3

Water Absorption, Saturation, Immersion

ASTM D570

% by wt.

1.5

MECHANICAL

Property

Test

Unit of Measure

Value

Tensile Strength

ASTM D638

psi

12500

Tensile Modulus

ASTM D638

psi

730000

Tensile Elongation at Break

ASTM D638

%

2.6

Flexural Strength

ASTM D790

psi

18000

Flexural Modulus

ASTM D790

psi

1000000

Compressive Strength

ASTM D695

psi

43000

Compressive Modulus

ASTM D695

psi

971000

Hardness

ASTM D785

NA

Rockwell E90

IZOD Impact-Notched

ASTM D256

ft-lb/in

0.7

Dynamic Coefficient of Friction

QTM 55007 (Dry vs Steel)

NA

0.22

Wear K Factor

QTM 55010

in³-min/ft-lbs-hr

112

Limiting PV

QTM 55007

psi-fpm

43000

THERMAL

Property

Test

Unit of Measure

Value

Coefficient of Linear Thermal Expansion

ASTM D696

x 10-5 in./in./℉

0.9

Max Continuous Operating Temp

℃

260

huashidu5

500

Minimum Operating Temp

℃

-200

℉

-328

Thermal Conductivity

ASTM C117

BTU-in/ft²-hr-℉

3.6

Flammability Rating

UL94

NA

V-0

COMPLIANCE

Description

Value

FDA

No

USDA

No

NSF

No

3-A Dairy

No

Canadian Food Inspection Agency

No

USP Class VI

No

OTHER

Description

Value

UV Resistant

Yes

Related Keywords