Duratron®T4301 Bearing Grade PAI

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Duratron® T4301 PAI AE (aerospace) offers a very low expansion rate and coefficient of friction, and also exhibits little to no slip-stick in use. The addition of PTFE and graphite provides higher wear resistance compared to the unfilled Duratron® T4203 PAI grade, and also gives Duratron® T4301 PAI AE excellent dimensional stability capabilities over a wide temperature range. Duratron® T4301 PAI AE's flexural modulus of elasticity is higher than most other advanced engineering plastics, which allows it to excel in severe service wear applications in aerospace engineering such as non-lubricated bearings, seals, bearing cages, and reciprocating compressor parts.

Material Properties

Chemical and creep resistant

Excellent dimensional stability and machinability

Exhibits little to no slip-stick

High strength and stiffness

Low expansion rate

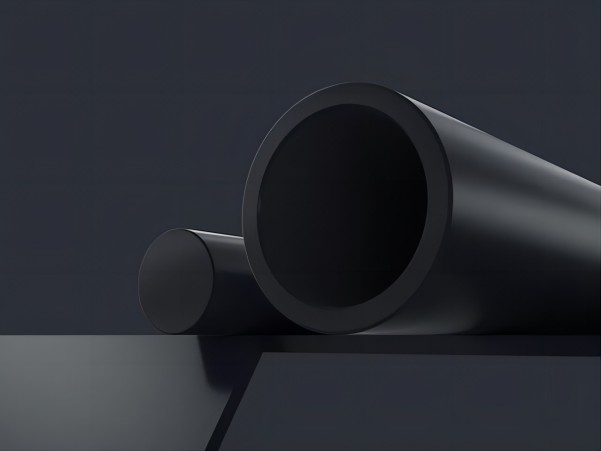

Available Geometries

Duratron® T4301 PAI AE stock shapes encompass a range of standard sizes in the following geometries: Rod, Plate

Available Colors

Duratron® T4301 PAI AE stock shapes come in the following colors: Black

Key Properties

Thermal Performance to 500°F (260°C) Continuous Use Temp

Excellent Wear Resistance

High Flex & Compressive Modulus

Ideal high Pressure and Velocity Bearing Applications

Low Coefficient of Friction (COF)

Limitations

Duratron® T PAI Grade Materials have a relatively high moisture absorption rate, parts used in high temperature service or made to tight tolerances should be kept dry prior to installation.

Thermal shock resulting in deformation can occur if moisture laden parts are rapidly exposed to temperatures above 400°F (205° C).

Chemical Resistance to Strong Bases, Steam and Some High Temperature Acids

Applications

Aerospace Components

Bushings & Bearings

Gears

Metal Replacement

Oil & Gas Components

Rollers

Seals

Thrust Washers

Wear Rings

Typical Properties of Duratron ® T 4301 PAI Extruded

| DETAIL | |

| Description | Value |

| Material Type | Imidized Amorphous Thermoplastic |

| Chemical Name | PAI Polyamide-imide |

| Trade Name | Duratron® T4301 PAI |

| Additives | Bearing Grade Additives |

| Color | Black-Green |

| Manufacturer | Mitsubishi Chemical Advanced Materials |

| PHYSICAL | |||

| Property | Test | Unit of Measure | Value |

| Density | ASTM D792 | g/cm³ | 1.45 |

| ASTM D792 | lb/in³ | 0.052 | |

| Water Absorption, 24 hrs, Immersion | ASTM D570 | % by wt. | 0.4 |

| Water Absorption, Saturation, Immersion | ASTM D570 | % by wt. | 1.5 |

| MECHANICAL | |||

| Property | Test | Unit of Measure | Value |

| Tensile Strength | ASTM D638 | psi | 15000 |

| Tensile Modulus | ASTM D638 | psi | 900000 |

| Tensile Elongation at Break | ASTM D638 | % | 3 |

| Flexural Strength | ASTM D790 | psi | 23000 |

| Flexural Modulus | ASTM D790 | psi | 800000 |

| Compressive Strength | ASTM D695 | psi | 22000 |

| Compressive Modulus | ASTM D695 | psi | 950000 |

| Hardness | ASTM D785 | NA | Rockwell E70 (M106) |

| IZOD Impact-Notched | ASTM D256 | ft-lb/in | 0.8 |

| Dynamic Coefficient of Friction | QTM 55007 (Dry vs Steel) | NA | 0.2 |

| Wear K Factor | QTM 55010 | in³-min/ft-lbs-hr | 10 |

| Limiting PV | QTM 55007 | psi-fpm | 22500 |

| THERMAL | |||

| Property | Test | Unit of Measure | Value |

| Coefficient of Linear Thermal Expansion | ASTM D696 | x 10-5 in./in./℉ | 1.4 |

| Heat Deflection Temp | ASTM D648 | ℃ at 264 psi | 279 |

| ASTM D648 | ℉ at 264 psi | 534 | |

| Max Continuous Operating Temp | ℃ at 264 psi | 260 | |

| ℉ | 500 | ||

| Minimum Operating Temp | ℃ at 264 psi | -200 | |

| ℉ | -328 | ||

| Thermal Conductivity | ASTM C117 | BTU-in/ft²-hr-℉ | 3.7 |

| Flammability Rating | UL94 | NA | V-0 |

| ELECTRICAL | |||

| Property | Test | Unit of Measure | Value |

| Dielectric Constant at 1 MHz | ASTM D150 | NA | 5.4 |

| Dissipation Factor at 1 MHz | ASTM D150 | NA | 0.037 |

| Surface Resistivity | ASTM D257 | ohm/square | >10^13 |

| COMPLIANCE | |

| Description | Value |

| FDA | No |

| USDA | No |

| NSF | No |

| 3-A Dairy | No |

| Canadian Food Inspection Agency | No |

| USP Class VI | No |

| OTHER | |

| Description | Value |

| UV Resistant | Yes |

Related Keywords