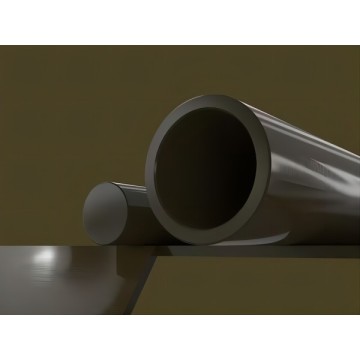

Torlon PAI carbon filled TECAPAI CM XP730 black

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

The addition of 30% carbon fibers to Solvay Torlon® plastic is what gives TECAPAI CM XP730 black compression molded polyamide-imide its excellent combination of physical properties. It is Ensinger's version of a product commonly referred to in web searches as “torlon 7530”. This high performing melt processable PAI material has several key material properties such as the highest tensile and compression strength of the compression molded grades, coupled with a very low CLTE. This Torlon plastic also maintains strength and stiffness at elevated temperatures.

Finally, TECAPAI CM XP730 black offers an outstanding strength to weight ratio, and excellent chemical resistance. Users should find these Torlon material properties useful for aerospace components and metal spinning tooling, in addition to other larger parts that require strength and stiffness for metal replacement. Minimum order quantities as low as one piece make these PAI shapes even more versatile.

FACTS

Chemical designation

PAI (Polyamide-imide)

Color

black

Density

1.47 g/cm3

OVERVIEW

What is the Material: PAI 30% Carbon is an imidized amorphous material filled with carbon fibers.

Key Material Features: This material is beneficial in applications requiring reinforced structural properties, while maintaining the properties of other PAI materials including high strength, dimensional stability, diverse chemical resistance, and it maintains its properties at elevated temperatures.

Other Considerations: This material is attacked by hot water and steam. The carbon filler reinforces the structural properties, but it is not abrasive like glass filled can be.

| Property | Value | Typical ASTM Test |

|---|---|---|

| Chemical Designation | (PAI) Polyamide-imide | |

| Trade Names (®, ™) | Torlon, Tecapai CM XP730, Duratron T7130 | |

| Filler | 30% Carbon Filled | |

| Color | Black | |

| Density (g/cm^3) | 1.47 | D 792 |

| Property | Value | Typical ASTM Test |

|---|---|---|

| Modulus of Elasticity (Tensile Test) (psi) | 1200000 | D 638 |

| Tensile Strength at Yield (psi) | 12500 | D 638 |

| Tensile Strength at Break (psi) | 24000 | D 638 |

| Elongation at Break (%) | 4 | D 638 |

| Flexural Strength (psi) | 37000 | D 790 |

| Modulus of Elasticity (Flexural Test) (psi) | 1300000 | D 790 |

| Compression Strength: 10% Strain (psi) | 40000 | D 695 |

| Compression Strength: 1% Strain (psi) | 6500 | D 695 |

| Compression Modulus (psi) | 700000 | D 695 |

| Impact Strength (Izod) (ft-lbs/in) | 1.1 | D 256 |

| Hardness (D) | 94 | D 785 |

| Hardness (E) | 90 | |

| Coefficient of Friction (Kinetic, 40 psi, 50 fpm) | 0.15 | D 3702 |

| Coefficient of Friction (Static) | 0.13 | D 3702 |

| Wear (K) Factor (in^3-min/ft-lbs-hr) (Against Steel, 40 psi, 50 fpm) | 7.50E-9 | D 3702 |

| Property | Value | Typical ASTM Test |

|---|---|---|

| Glass Transistion Temperature (°F) | 529 | D 3418 |

| Deflection Temperature (°F) (264 psi) | 526 | D 648 |

| Service Temperature Continuous (°F) | 500 | |

| Thermal Expansion (CLTE) (in/in/°F) | 1.62E-5 | D 696 |

| Thermal Conductivity (BTU-in/hr-ft^2-°F) | 3.60 |

| Property | Value | Typical ASTM Test |

|---|---|---|

| Moisture Absorption (%) (24 Hours) | 0.3 | D 570 |

| Moisture Absorption (%) (Saturated) | 1.5 | D 570 |

| Flammability | V-0 |

Related Keywords