TECAPAI™ CM XP403 green

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Air, Express, Land

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 100000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Transportation: | Ocean,Air,Express,Land |

| Port: | Shenzhen,Guangzhou,Hongkong |

TECAPAI CM XP403 green is a compression moulded Torlon® plastic material that is unreinforced and delivers an excellent combination of physical properties. Made from Solvay Torlon® powder, this PAI material offers excellent ductility and toughness as well as good strength and stiffness at elevated temperatures. Additional characteristics include good dielectric properties, wear performance, and excellent chemical resistance in its staple, which is typical of polyamide-imide properties.

Users will find this PAI polymer extremely useful in applications such as electrical connectors, wear components and large parts that require strength and stiffness. Because it is compression moulded, TECAPAI CM XP403 green can be ordered by the piece, adding to its usefulness and versatility. TECAPAI CM XP403 green is Ensinger's version of a product commonly referred to in web searches as "torlon 4503".

Torlon® PAI is a registered trademark of the Solvay Group.

FACTS

Chemical designation

PAI (Polyamide-imide)

Colour

green

Density

1.41 g/cm3

MAIN FEATURES

good wear properties

excellent strength and stiffness

excellent dimensional stability

very good thermal stability

excellent chemical resistance

TARGET INDUSTRIES

electronics

aircraft and aerospace technology

oil and gas industry

chemical and refinery industry

process engineering

CONSTRUCTION MATERIALS TORLON PAI

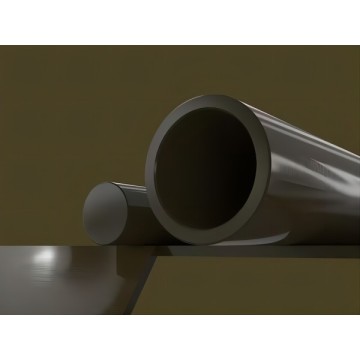

Polyamide-imide plastics are manufactured under the brand name TECAPAI using Torlon® PAI polymer. The TECAPAI family of high temperature plastics offers polyamide-imide shapes in various modifications. PAI rods and plates are made by two different processing techniques, including extrusion molding and compression molding. Extrusion offers the advantage of producing molds that exhibit physical properties close to injection molding. PAI compression schemes can be produced with a minimum order quantity as low as one piece.

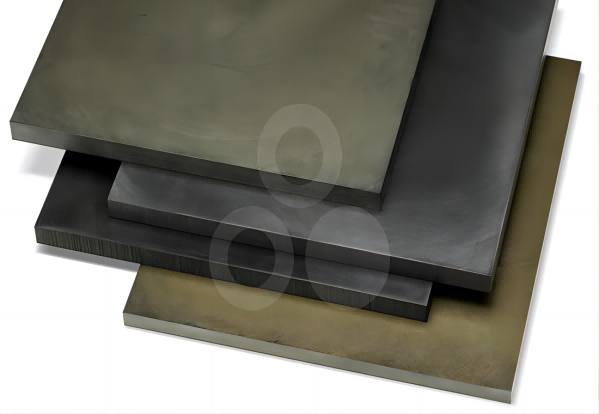

Compression moulded PAI plates, tubes and rods

Unreinforced Torlon PAI – TECAPAI CM XP403 green

30% glass filled Torlon PAI – TECAPAI CM XP530 black-green

Bearing grade Torlon PAI – TECAPAI CM XP440 black-green

30% carbon filled Torlon PAI – TECAPAI CM XP730 black

| THERMAL PROPERTIES | VALUE | UNIT | PARAMETER | NORM |

|---|---|---|---|---|

| Glass transition temperature | 285 | C | DIN EN ISO 11357 | |

| Thermal expansion (CLTE) | 4,2 | 10-5*1/K | 23-60°C, longitudinal | DIN EN ISO 11359-1;2 |

| Thermal expansion (CLTE) | 4,3 | 10-5*1/K | 23-100°C, longitudinal | DIN EN ISO 11359-1;2 |

| Thermal expansion (CLTE) | 4,7 | 10-5*1/K | 100-150°C, longitudinal | DIN EN ISO 11359-1;2 |

| OTHER PROPERTIES | VALUE | UNIT | PARAMETER | NORM |

|---|---|---|---|---|

| Flammability (UL94) | V0 | - | 3,2 mm | - |

Related Keywords