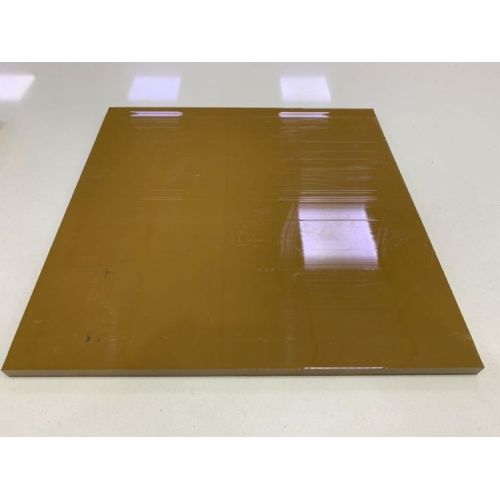

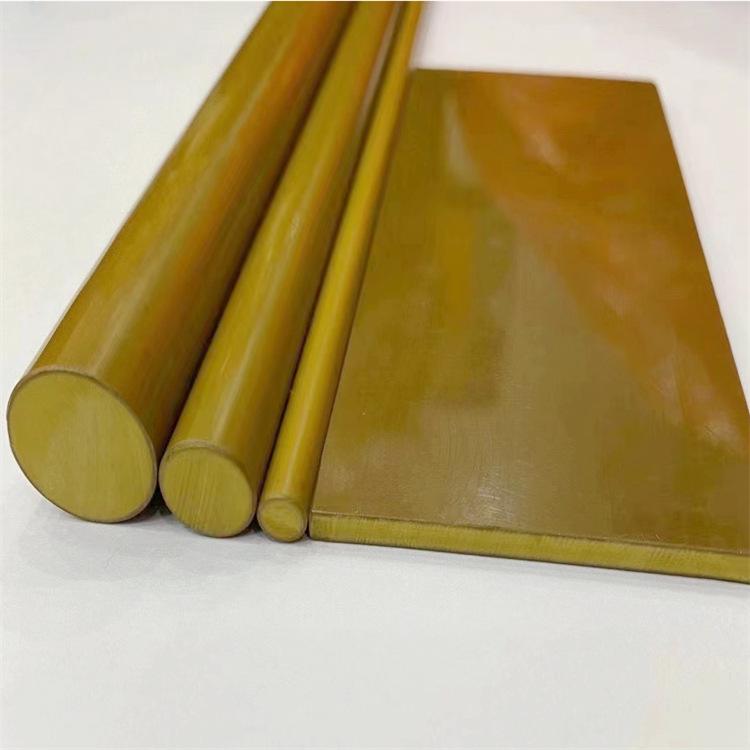

Torlon PAI Plastic Sheets

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU,DDP |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shenzhen,Guangzhou,Hongkong |

Torlon® polyamide-imide (PAI) is the highest performing, melt-processable thermoplastic. The amorphous polymer has exceptional resistance to wear, creep and chemicals and performs well under severe service conditions up to 260°C (500°F). Torlon® PAI also has superior electrical and structural characteristics at high temperatures, an extremely low coefficient of linear thermal expansion, and exceptional dimensional stability. Typical applications include non-lubricating bearings, seals, valves, compressors, and piston parts, bearing cages, bushings, and thrust washers.

Torlon® PAI Torlon® is a high strength, high temperature (500°F max) polymer that is injection molded and oven “cured” to produce a thermoset polymer with excellent bearing properties. Torlon® has the highest tensile strength of all non-filled, injection moldable materials

Excellent long-term strength and rigidity at temperatures up to 275°C

Excellent wear resistance

Excellent toughness from low temperature to high temperature of 275°C

Resistant to strong acids and most organics

Natural flame retardant

Low coefficient of linear thermal expansion

TORLON PAI PAI sheet

There are three different grades of material.

Wear Resistance Grades High Strength Grades

4301 General purpose wear resistance

4203 Unfilled, highest impact strength, good electrical properties

4275 Good wear resistance at high velocities

5030 30% glass fiber, high strength and rigidity, very low creep

4630 Excellent wear resistance in dry environments

7130 30% carbon fiber, highest stiffness, best fatigue resistance, electrically conductive

4435 Good wear resistance at high velocities and high pressures

4645 Excellent wear resistance in lubricated environments

Torlon® polyamide-imide (PAI) Torlon 4203 PAI Applications

Parts made from Torlon® PAI polymers perform under conditions generally considered too severe for thermoplastics. Typical applications include aircraft hardware and fasteners, automotive transmission and powertrain components, and oil & gas exploration and recovery equipment. The material’s excellent electrical insulating properties have made it a common choice for semiconductor fabrication and testing as well as electrical and electronic components.

Amide-imide (AI) powders are widely used in high-performance, non-stick, and corrosion-resistant coatings for a variety of other demanding industrial uses

Torlon® PAI Product Line

Torlon® PAI products fall into two main categories: wear-resistant grades and high strength grades. Extrusion and compression molding are used to produce stock shapes for machining and low-volume production. Amide-imide (AI) powders are also available.

Wear-resistant grades offer tailored combinations of mechanical and tribological properties, along with excellent chemical resistance and high thermal stability. This accounts for Torlon® PAI’s broad acceptance in replacing metal over a wide range of temperature and PV conditions, even when lubrication is marginal or non-existent.

High-strength grades exhibit metal-like performance at elevated temperature and are routinely specified for precision components used in repetitive-use, load-bearing operations. Glass-fiber and carbon-fiber-filled grades retain their strength and stiffness at high temperature, with the added benefit of low creep and excellent fatigue resistance.

Amide-imide (AI) powders are used to manufacture high-temperature adhesives, non-stick coating primers, composite matrices, coatings and films.

Related Keywords