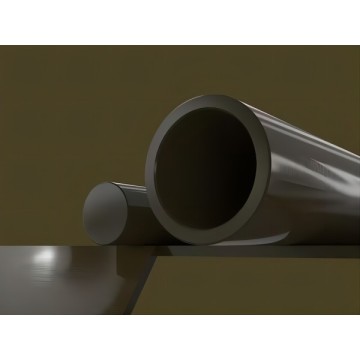

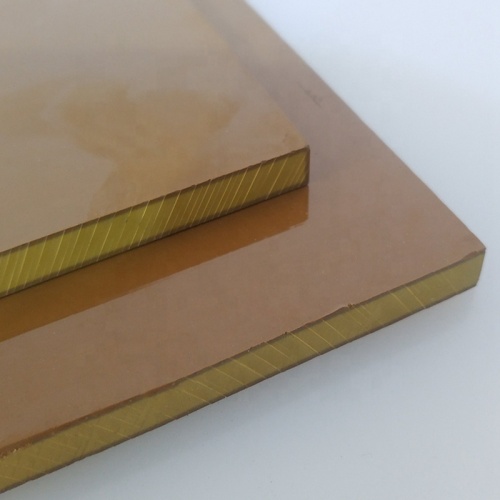

Duratron PAI Torlon Rod Sheet Tube

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | DDU,EXW,CIF,CFR,FOB,DDP |

| Certificate: | ROHS REACH SGS ISO |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shenzhen,Guangzhou,Hongkong |

HONYPLAS®PAI material is also known as: polyamide-imide. It also has advantages. The allowable working temperature in the air is very high (continuous work at 250°C). The best size in the temperature range of 250 ℃, excellent wear resistance and friction properties. Outstanding UV resistance. Excellent resistance to high-energy radiation (γ-rays and X-rays) The material is mostly used in occasions with extremely high wear resistance requirements, such as non-lubricated bearings, seals, bearing isolation rings and reciprocating compressor parts. It is a high-strength plastic with the highest strength and rigidity among thermoplastics at 275°C (525°F). This product has outstanding abrasion resistance, creep resistance, and chemical resistance (including resistance to strong acids and most organics), making it very suitable for applications in harsh environments.Excellent long-term strength and rigidity at temperatures up to 275°CExcellent wear resistanceExcellent toughness from low temperature to 275°C high temperature conditions.Resistant to strong acids and most organicsNatural flame retardant.Low coefficient of linear thermal expansion

PAI sheet (polyamide-imide) is an extremely strong and stiff plastic material. It is often used in elevated temperature environments,other thermoplastics would lose their mechanical properties at the same hot tenperature . Can best stability at 270 degrees Celsius.PAI is a very dimensionally stable material with an extremely low coefficient of thermal expansion making it an excellent choice for applications that require machining to tight tolerances. PAI sutable used in processing machine part or some engineering project.

Working temperature: 260-400 degree

Color: natural, black, yellow rice

Density: 1.40g/cm3 (the actual density is subjected to the final confirm)

Tolerence: +/-0.1-0.5mm, according to different sizes

HONYPLAS®PAI Characteristics:

1.heat-resistant:can work under very high temperature in atmosphere(continuously work under 250°C)

2.perfect dimension stability:can keep perfect dimension stability under 250°C

3.high strength:his high strength is incomparable in the unreinforced industrial plastic area at present

4.excellent wear-resistance

5.outstanding ultraviolet radiation resistance

6.outstanding anti-radiation

7.inherent low flammability

8.good viscidity,flexibility,alkaline resistence

9.good electrical insulation

HONYPLAS®PAI Industry Application:

testing equipment,high speed bearing,heat resistant gear of the electric equipment,mold accessories,food machine,electron and semiconductor industrial,spaceflight area,chipset and socket,cup-bearing welding,oil drilling equipment and so on.

HONYPLAS®PAI Sizes available:

0.5mx0.5m 1mx1m 1mx2m 0.5mx1m or small pieces; special sizes can be cut as requirement.

Thickness: 1mm-100mm

HONYPLAS®PAI Technical Data Sheet

Property

Test Method

Unit

High strength type

Wear resistance type

4203L

5030

7130

4301

4275

4435

4630

4645

Tensile strength

D638

MPa

152

221

221

113

117

94

81.4

114

Elongation at break

D638

%

7.6

2.3

1.5

3.3

2.6

1.0

1.9

0.8

Flexural strength

D790

MPa

282

374

310

200

23℃

244

338

355

219

212

152

131

154

135℃

174

251

263

165

157

129

232℃

120

184

177

113

111

91

Flexural modulus

D790

GPa

7.9

14.1

24.6

9.6

23℃

5.0

11.7

19.9

6.9

7.3

14.8

6.8

12.4

135℃

3.9

10.7

15.6

5.5

5.6

11.2

232℃

3.6

9.9

13.1

4.5

5.1

10.3

Shear strength

D732

MPa

128

140

120

112

77

60

85

Izod impact strength(3.2mm)

D256

J/m

Notched

142

79

47

63

84

43

48

37

No notch

1062

504

340

404

250

219

160

107

Distortion temperature(1.82MPa)

D648

℃

278

282

282

279

280

278

279

281

CLTE

D696

ppm/℃

30.6

16.2

9.0

25.2

25.2

14.4

11.5

4.5

Flammability grade

UL94

94 V-0

94 V-0

94 V-0

94 V-0

94 V-0

94 V-0

Limit oxygen index

D2863

%

45

51

52

44

45

Volume resistivity

D257

ohm-cm

2x10^17

2x10^17

8 x 10^15

8 x 10^15

2 x 107

Density

D792

g/cm3

1.42

1.61

1.48

1.46

1.51

1.59

1.56

1.56

Hardness(Rockwell E)

D785

86

94

94

72

70

62

Water absorption(24H)

D570

%

0.33

0.24

0.26

0.28

0.33

0.12

0.2

0.3

HONYPLAS®PAI Main product

Related Keywords