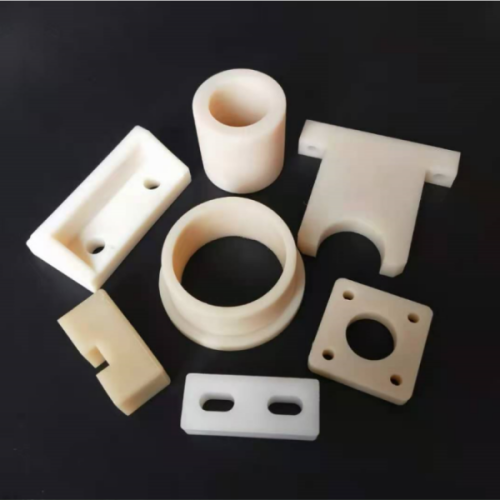

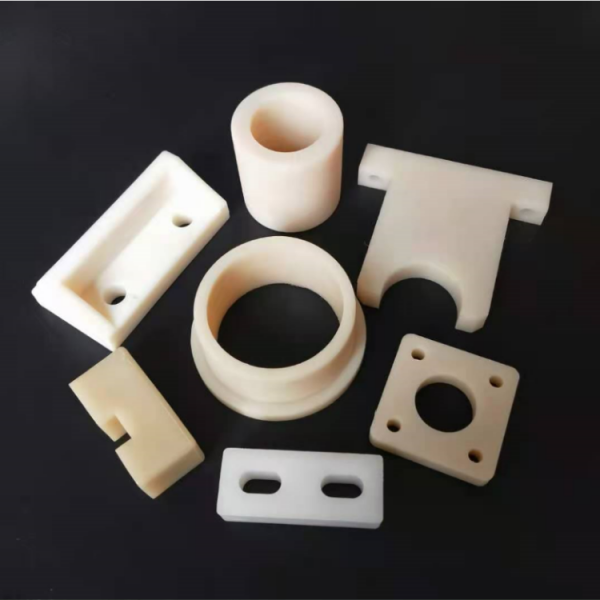

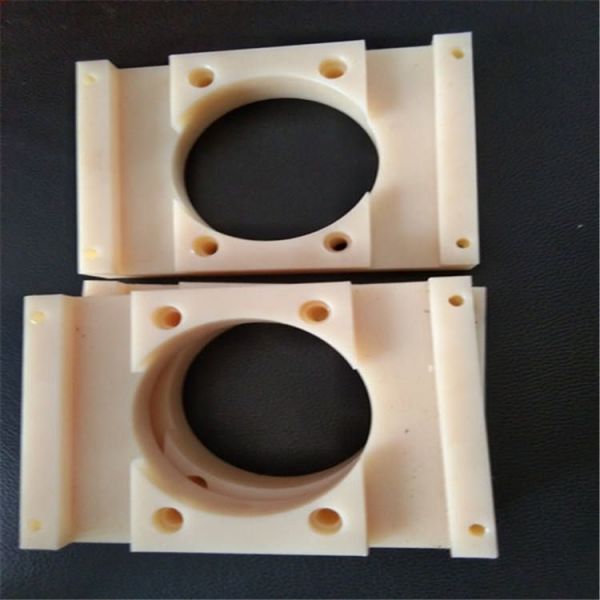

Nylon (PA) CNC Machining

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 10000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Introduction to the characteristics of nylon machined parts

Nylon material in precision machining is also a commonly used materials, often used to process small precision fixtures, due to the hardness, toughness and processing characteristics of the nylon material, in precision parts processing has played an irreplaceable role, let's take a look at the characteristics of nylon machining parts!

The characteristics of nylon machining parts:

Nylon has good overall performance, including mechanical properties, heat resistance, abrasion resistance, chemical resistance and self-lubricating, and low coefficient of friction, a certain degree of flame retardant, easy to process, suitable for glass fibers and other fillers filled with enhancement modification to improve performance and expand the range of applications.

As nylon has non-toxic, lightweight, excellent mechanical strength, abrasion resistance and good corrosion resistance, it is widely used instead of copper and other metals in machinery, chemical industry, instrumentation, automotive and other industries in the manufacture of bearings, gears, pump leaves and other parts. Polyamide melt spun into silk has high strength, mainly synthetic fibers and can be used as medical sutures.

Corrosion resistance: the chemical stability of nylon is very good, almost any chemical reagent is very stable, even at higher temperatures, can still maintain good chemical stability. In addition, it is resistant to hot water and steam. It can be used for a long time in steam at 200~250 ℃.

Heat resistance: nylon has a high melting point, generally above 240 ℃, aromatic nylon heat resistance is higher than aliphatic nylon, if you add a certain amount of reinforcing filler, its thermal stability can be greatly improved, the heat distortion temperature can be as high as 250 ℃.

Solvent resistance: nylon's chemical stability is good, alkali resistance, weak acid resistance; and belongs to the solvent-resistant plastics, especially resistant to aromatic compounds and commonly used organic solvents, can be used for chemical, chemical instrumentation; in some environments where metal is prone to rust, such as water meters, can be used in place of nylon materials.

Related Keywords