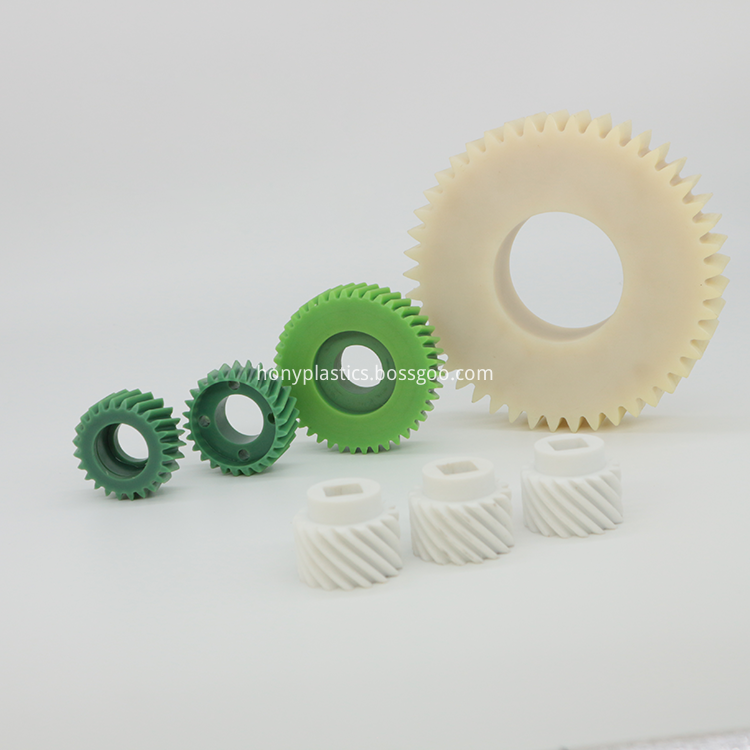

Nylatron® MC 901 PA6 Polyamide straight bevel gear

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen, Guangzhou, HongKong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | Enough |

|---|---|

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Guangzhou,HongKong |

Nylatron® MC 901 Small Plastic for Electric Motor And Shaft Nylon Field Gear Coupling Although the strength of MC nylon gear is significantly lower than that of the corresponding metal gear, due to its low friction and inertia, as well as the elasticity (bending) of the thermoplastic gear teeth, it can be a direct substitute for metals in many applications -- especially non-ferrous, cast iron, and unhardened steel.Nylon has good overall performance, including mechanical properties, heat resistance, wear resistance, chemical resistance and self-lubrication, and low coefficient of friction, a certain degree of flame retardancy, easy processing, suitable for filling with glass fiber and other fillers to enhance rigidity, improve performance and expand the range of applications, followed by its overload protection function, when the torque is too large, the gear itself is damaged, power transmission interrupted so as to protect the lower device or personal safety, reduce losses.

Because nylon has non-toxic, light weight, excellent mechanical strength, wear resistance and good corrosion resistance, so it is widely used instead of copper and other metals in machinery, chemical industry, instrumentation, automotive and other industries to manufacture bearings, gears, pump leaves and other parts. Polyamide melt spinning into silk has high strength, mainly as a synthetic fiber and can be used as medical suture

Oil nylon it is truly self-lubricating nylon, oil nylon in the casting process formed a liquid lubrication system, making oil nylon bearing life significantly improved, reaching 6 times the life of ordinary nylon bearings and 25 times the life of phosphor bronze bearings! The lubricant contained in oil nylon will not be lost, adsorbed and depleted, and does not need to be re-added. Lubricant in oil nylon greatly broadens the use of nylon, especially for some parts that cannot be lubricated

MC Nylon gear Technical performance parameters

Density: 1.15g/cm3

Impact strength: 8.5kJ/m2

Tensile strength: 80MPa

Shore D hardness: 80-85

Compression strength: 110MPa

Friction coefficient: 0.1-0.3 on steel surface

Continuous working temperature: -80-125 degrees

Various types of MC nylon with commonly used bearing alloys

Test results during oil-free lubrication on M-2000 abrasion testing machine

MC Nylon gear has the following advantages

◆ low operating noise

◆ no lubrication operation

◆ lower inertia than conventional metal gears

◆ corrosion resistance

HONY plastic processing advantage:

Plastic gears material:Nylon;POM;UHMWPE

We manufacture plastic parts according to customers' designs;

We can offer material certification,test report and relate surface-treatment report;

Platic gears process:CNC machining,Milling,Drilling,Turning;

Products shown on the website are OEM;

Customized designs are welcome;

Plastic gears OEM/ODM orders are welcome;

Our Service

1)We are a manufacturer integrating industry and trade.

2)We foceus on processing plastic products for 13 years.

3)We are located in guangzhou huangpu,near guangzhou wuchong port.

4)Flexible delivery,Super quality,Factory price.

5)OEM Service: customize color,size,material.

6)MOQ:1pc.

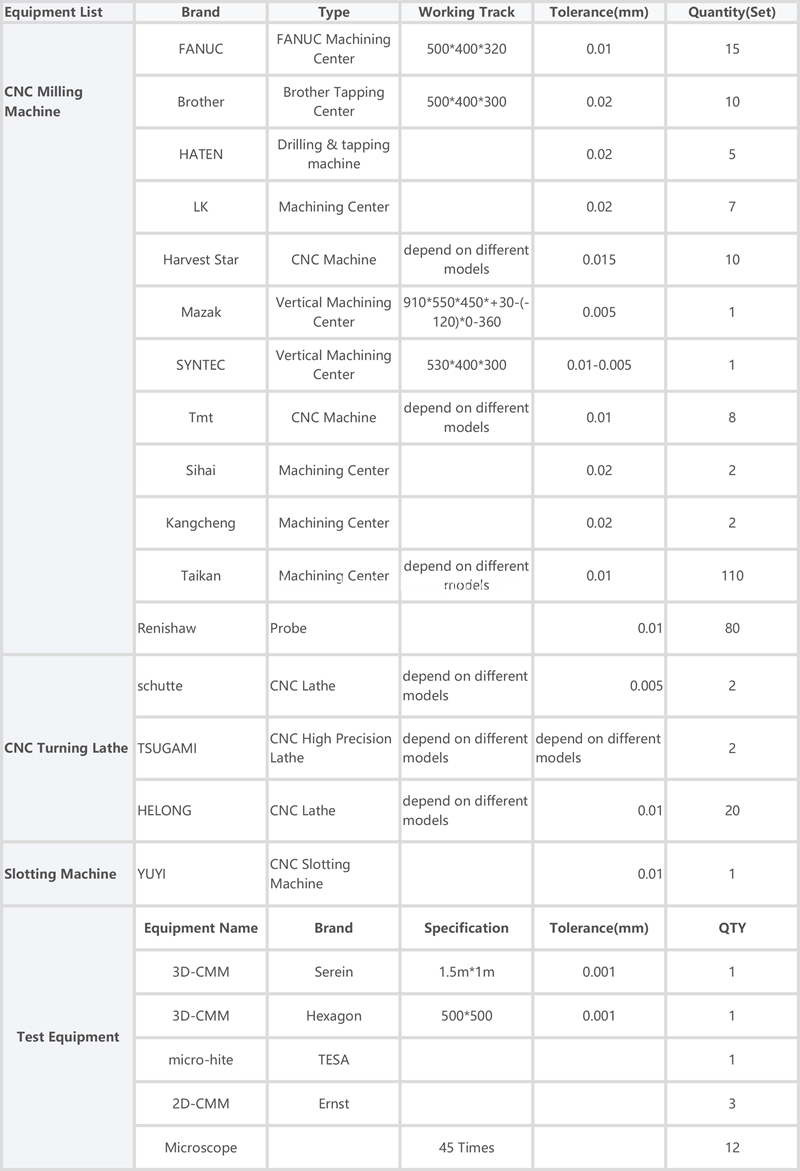

Processing equipment:

CNC machinery center,engraving machine,Cnc lathe and other equipment processing services.

Processing materials:

PTFE,POM,Nylon,UHMWPE,PEEK,HDPE,PU,PTE.ect(only plastic material)

Commitment:

if the parts cannot be used because of the processing problems,we will be responsible for free repair or reprocessing,and bear the

round-trip freight.

Our machine lait

CNC Service

Our machine

Related Keywords