Extrusion Processing Guide PA 6 Polyamide 6

-

$2.90100-499 Meter

-

$2.80500-999 Meter

-

$2.70≥1000 Meter

- Transportation:

- Ocean, Land, Express, Air

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Certificate: | REACH ROHS |

| Transportation: | Ocean,Land,Express,Air |

| Port: | Shenzhen,Guangzhou,Hongkong |

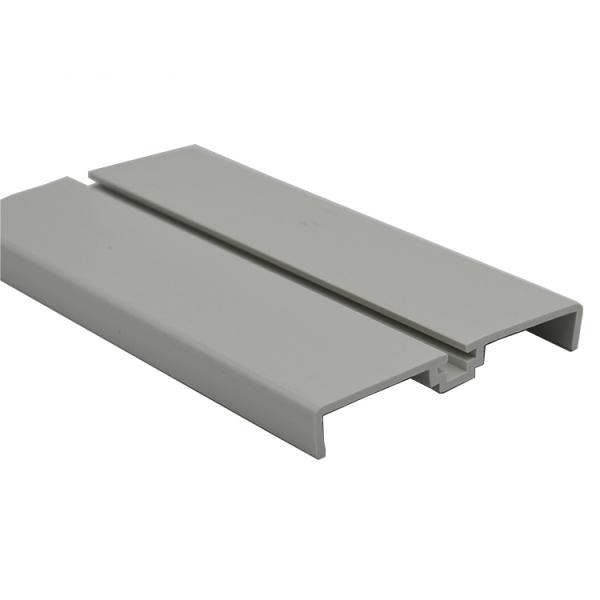

Nylon profiles are made by the extrusion process of polyamide (PA) that is notably known with its commercial name, Nylon.

In general, with Nylon profiles, the products manufactured are applied where excellent mechanical properties are required like pneumatic tubes that are resistant to high pressure and temperatures.Polyamide profiles have excellent abrasion resistance and can also be utilized as sliding tracks for metal ball bearings. PA also has a considerable weathering resistance. When glass fibers are added to polyamide, the mechanical properties improve significantly, as for example, specific plastic profiles are extruded for thermal break windows.

Polyamide-Nylon properties: excellent mechanical characteristics, abrasion, chemical (fatty oils, solvents), and high temperature resistance; strong resistance to low temperatures and weathering. It can be formulated with fibers (glass and carbon) to increase its elastic modulus.

Through the extrusion process, the following Nylon profiles can be manufactured:

Thermal break window profiles

Nylon Bars

Nylon rods

Nylon tubes

Pneumatic tubes

Sliding track profiles

Various sliding components

Technical profiles for mechanical industry

Technical profiles for industrial applications

Custom profiles

The differences and uses of ABS, PVC, PP, PE, PA, PS, PC and nylon profiles

There are many materials in the industrial manufacturing of plastic products, the following is a brief introduction to several major plastic materials, so that you have a general understanding of the production of plastic materials, including the main materials are ABS, PVC, PP, PE, PA, PS, PC, nylon. Introduced as follows;

PP: polypropylene. Odorless, tasteless, non-toxic. It is the lightest of the commonly used resins. Excellent mechanical properties. Good heat resistance, continuous use temperature up to ll0-120℃. Good chemical stability, does not interact with most chemicals except for strong oxidizing agents. Water resistance is particularly good. Excellent electrical insulation. However, it is easy to age and has poor impact strength at low temperature. Application areas Used for making injection products, films, pipes, plates, fibers, coatings, etc. Widely used in household appliances, automobile, chemical industry, construction, light industry and other fields.

PVC: Low molecular weight is easily soluble in solvents such as ketones, esters and chlorinated hydrocarbons. The high molecular weight ones are insoluble. PVC resin is processed and molded to obtain PVC plastic. Its monomer cost is low, the production process is mature, and it is easy to be processed and molded. It has good acid and alkali resistance, abrasion resistance, electrical insulation, and non-combustibility; however, its thermal stability and light resistance are poor. 140°C decomposition releases hydrogen chloride, and stabilizers need to be added during processing and molding. Low softening temperature, limited to 80 ℃ below the use. According to the amount of plasticizers added, soft plastics and hard resins can be produced. Soft plastics can be used as wire and cable coverings and other insulation materials, can be made into transparent film, used as raincoats, tablecloths, agricultural seedling film, etc.; also used to make artificial leather, foam and chlorine fiber. Hard plastic can be used to make plates, pipes, storage tanks, absorption towers, etc. Vinyl chloride polymerization by suspension method can be obtained powder resin, if the emulsion method of polymerization, can be obtained paste resin.

PE: Polyethylene is odorless and non-toxic. Chemical resistant, insoluble in solvents at room temperature. Low temperature resistance, low temperature use temperature -70 ~ -100 ℃. Good electrical insulation, low water absorption. Physical and mechanical properties vary according to density. Industrial low-density polyethylene mainly uses high-pressure (110-200MPa), high-temperature (150-300 ℃) free radical polymerization. Others use low-pressure coordination polymerization, sometimes the same set of devices can produce density 0.87 ~ 0.96g/cm3 polyethylene products, called full-density polyethylene process technology. Polyethylene can be processed into films, wire and cable sheathing, pipes, various hollow products, injection molding products, fibers, etc. It is widely used in agriculture, packaging, electronics and electrical appliances. It is widely used in agriculture, packaging, electrical and electronics, machinery, automobiles, daily miscellaneous products, etc.

PS: Polystyrene. Mainly used as audio-visual products and CD disk case, lamps and interior decoration parts, high-frequency electrical insulation parts. Its biaxially oriented film is the main material for packaging and electrical industry.

ABS: ABS plastic. ABS can be divided into general purpose grade (including various impact resistant grade), flame retardant grade, heat resistant grade, electroplating grade, transparent grade, structural foam grade and modified ABS according to different uses. General purpose grade is used for manufacturing gears, bearings, handles, machine housings and parts, various instruments, computers, recorders, TV sets, telephone housings and toys, etc.; flame retardant grade is used for manufacturing electronic parts, such as computer terminals, machine housings and various household appliances; structural foam grade is used for manufacturing electronic device housings, etc.; heat resistant grade is used for manufacturing automation instruments and motor housings in power plants, etc.; electroplating grade Used in the manufacture of automotive parts, various knobs, nameplates, decorative items and daily necessities; transparent grade is used in the manufacture of degree plates, food trays in refrigerators, profiles, profiles, etc.

PC: Polycarbonate is a common material in daily life. Due to its colorless transparency and excellent impact resistance, common daily applications are optical discs, eye pieces, water bottles, bulletproof glass, goggles, bank security glass, headlights, animal cages pet cages, cabinet light shades, commercial lighting long strip shades, architectural profiles , luggage side strips, plastic label holders.

POM plastic (polyoxymethylene) (Saigang ~ Telling) English name Polyoxymethylene (Polyformaldehyde) POM (polyformaldehyde resin) definition: polyformaldehyde is obtained from the polymerization of formaldehyde. It is high density, high crystallinity thermoplastic engineering plastic. It has good physical, mechanical and chemical properties, and especially has excellent friction resistance. It is because these excellent chemical and physical properties are comparable to steel, and lighter than steel, that it is called "race steel"! Specific gravity: 1.41-1.43g/cm3 Molding shrinkage: 1.2-3.0% Molding temperature: 170-200℃ Drying conditions: 80-90℃ 2 hours Material properties Good overall performance, high strength, high stiffness, good wear resistance, small water absorption, good dimensional stability, but poor thermal stability, easy to burn, easy to age in the atmosphere. Suitable for the production of wear-resistant parts, transmission parts, and chemical, instrumentation and other parts molding properties

1. Crystalline material, melting range is narrow, melting and solidification is fast, the material temperature is slightly lower than the melting temperature that crystallization occurs. Fluidity is medium. Small moisture absorption, can not be dried.

2. Low friction coefficient, good elasticity, easy to produce wrinkles and surface defects on the surface of plastic parts.

3. Very easy to decompose, the decomposition temperature is 240 degrees. There are irritating and corrosive gases when decomposing. Therefore, the mold steel should be made of corrosion-resistant materials.

Related Keywords