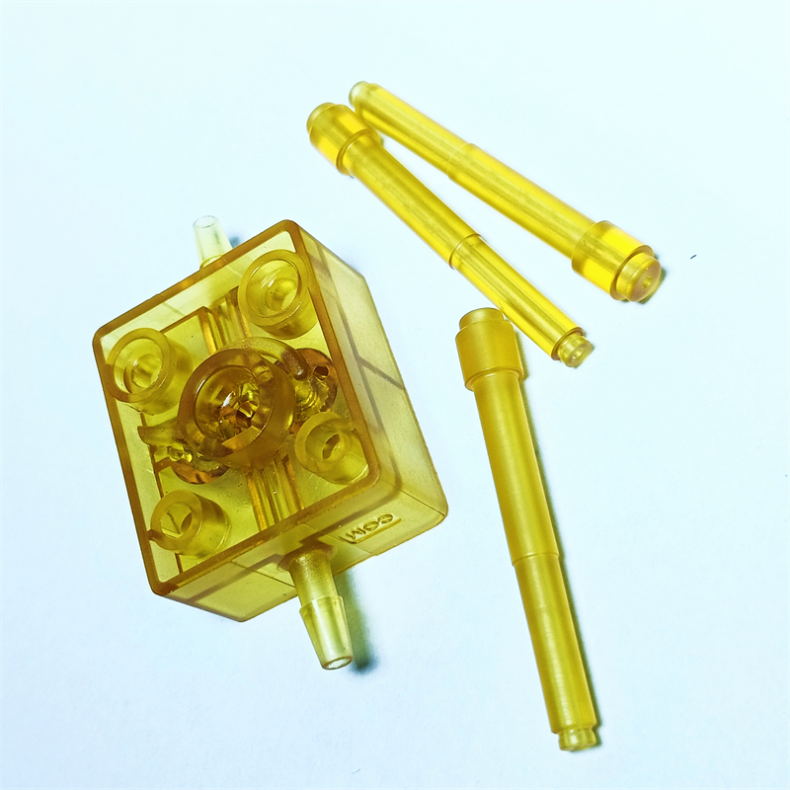

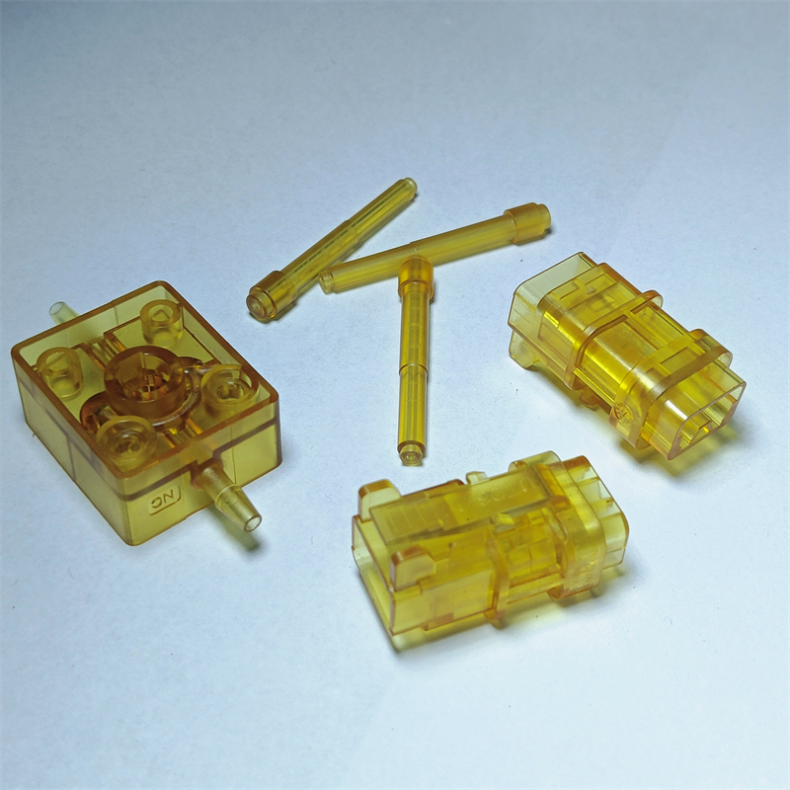

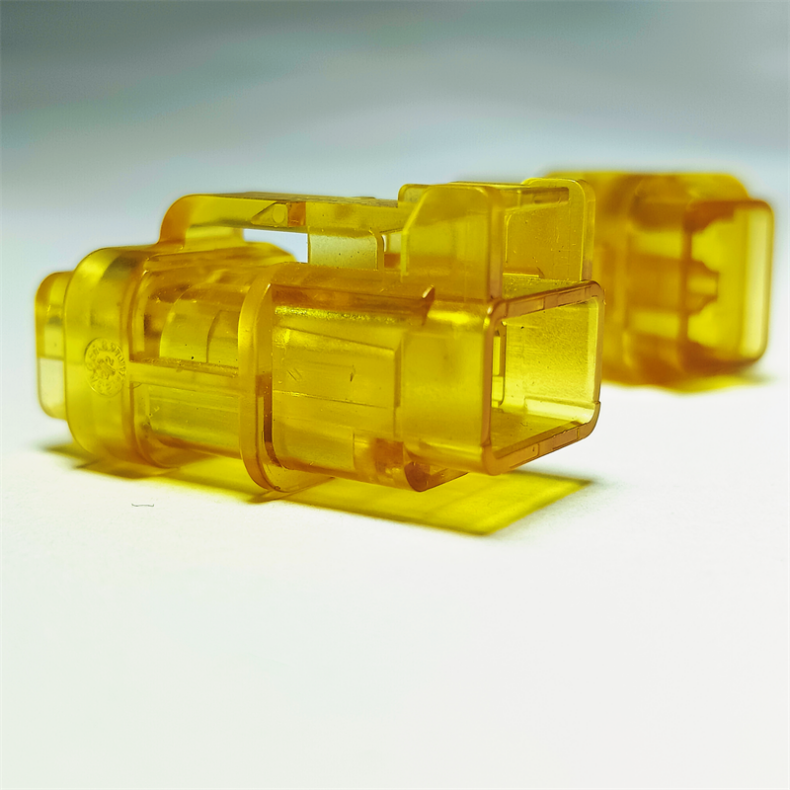

PPSU Polyphenylsulfone machined parts

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 100 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

Specialty Engineering Plastics PPSU Processing - Food Processing Solutions

Polyphenylsulfone PPSU has long been a leader in solutions for wear parts for food processing machinery, and is also a solution for applications requiring food-grade and FDA-compliant plastics, ranging from machined parts, to plastics processing for food processing technology to provide the latest metal detectable and food-grade performance solutions.

PPSU is designed for food contact applications as an ultra detectable food grade plastic. Unlike other detectable plastics that can only be inspected by one or two methods, PPSU materials are suitable for all three standard inspection processes: X-ray, optical scanning and metal detection. PEEK materials are ideal for food and beverage processing components as well as components for conveyor belt technology where detection of hazardous particles is critical, and where easy-to-maintain materials are always a welcome addition to the food processing industry. In the food processing industry, easy-to-maintain material plants or factories are always welcome. The high chemical resistance of these cladding systems allows them to withstand long periods of operation and reduces the need for frequent hygienic maintenance. These materials also have excellent structural strength, rigidity and fire resistance to withstand the rigors of food processing and production.

As a versatile material, PPSU can be used in many industries, and parts processed from UHPs can be used in virtually every aspect of the food production cycle, from rollers and guides in knife sharpening systems to wear strips for application butchery, the applications for specialty engineering plastics in the food processing industry are virtually endless, serving as a solution for power transmission processing and customized parts in food processing applications.

And with a full range of specification sizes and support for customization, specialty engineering plastics are particularly versatile, offering sheet and rod stock, custom pellets, and plastic alternatives to metal power transmission parts.

PPSU processing method

Injection Molding:

PPSU can be processed into parts and products of various shapes and sizes through the injection molding process.

The injection molding process usually involves heating PPSU pellets to a molten state, then injecting them into a mold and cooling them to obtain the desired product.

PPSU injection molded parts have high precision, high strength and good chemical resistance, and are suitable for the manufacture of highly loaded and demanding parts.

Extrusion:

The extrusion process involves heating and melting PPSU pellets through an extruder and then extruding them into continuous profiles or tubes through a mold.

The extrusion process can produce PPSU products with various cross-sectional shapes, such as pipes, rods, plates, etc.

PPSU extruded products have excellent heat resistance, chemical resistance and mechanical properties, and are suitable for applications that need to withstand high temperatures, high pressures and corrosive environments.

Blow Molding:

The blow molding process is mainly used to produce PPSU containers and bottles, etc.

The process involves injecting molten PPSU material into a mold and then blowing it to make it expand into the desired shape.

PPSU blow-molded products offer high strength, transparency and chemical resistance, making them suitable for the manufacture of containers that need to withstand high-temperature sterilization and corrosive media.

Mechanical Processing:

In addition to the above molding processes, PPSU can also be processed into various shapes and sizes by means of machining.

Mechanical processing includes cutting, drilling, grinding and other processes, according to the need to ding the shape and size of PPSU products.

PPSU material has excellent mechanical properties and chemical resistance, suitable for a variety of machining operations.

In the processing of PPSU, the following points need to be noted:

Temperature control: PPSU is processed at high temperatures and requires precise control of the heating and cooling process to ensure product quality and performance.

Mold design: The design of the mold is crucial to the quality and precision of PPSU products. It is necessary to ensure that the dimensional accuracy, surface finish and life of the mold meet the production requirements.

Raw material selection: Selection of high-quality PPSU raw materials to ensure product performance and stability is very important. Need to ensure the purity and homogeneity of raw materials.

Related Keywords

Related Keywords