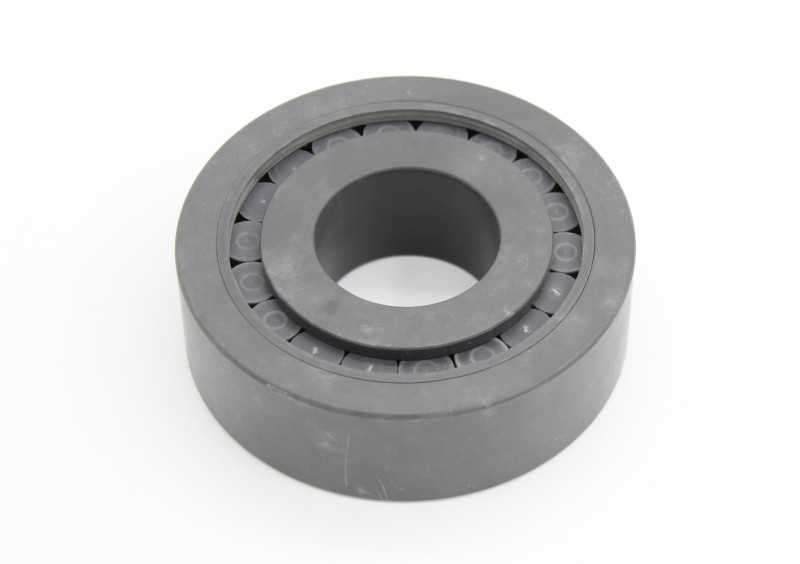

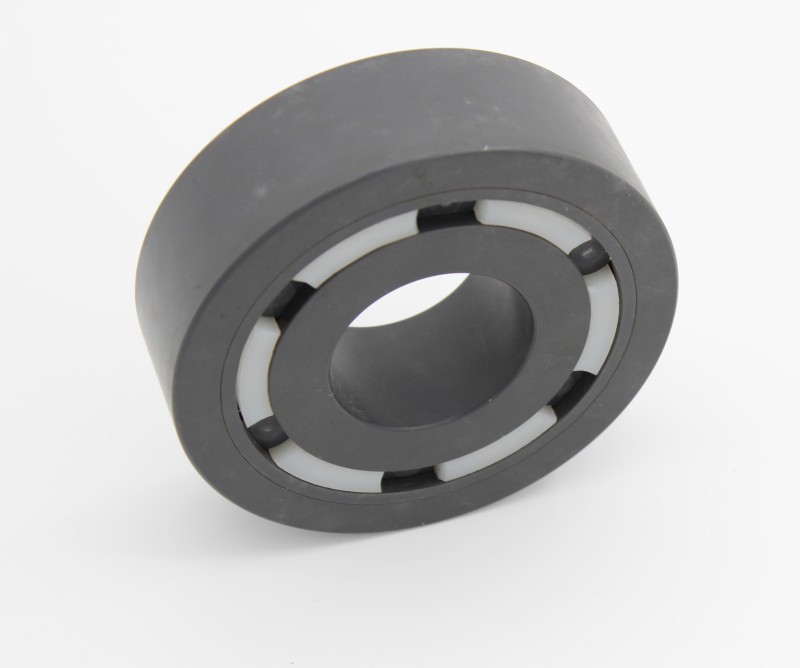

CNC PVC plastic Bearings

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 100 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

In the field of plastic materials, PVC (polyvinyl chloride) and TPR (thermoplastic rubber) are two common and distinctive materials. They have a wide range of applications in daily life, industrial production, and in many fields. Because they each have unique properties and characteristics, PVC and TPR have obvious differences in materials. In this paper, we will make a detailed comparison and analysis of PVC and TPR materials, in order to provide readers with a more comprehensive and in-depth understanding.

Second, the basic overview of PVC and TPR

1. PVC (polyvinyl chloride)

PVC, known as Polyvinyl Chloride, is a thermoplastic. It is polyvinyl chloride as the main component, by adding other additives such as plasticizers, stabilizers, etc., to improve its physical and chemical properties.PVC material has excellent corrosion resistance, heat resistance, flame retardant, mechanical properties, and good insulating properties.PVC material also has a good plasticity and environmental protection, can be made into a variety of shapes and sizes through a variety of processing methods.

2. TPR (Thermoplastic Rubber)

TPR, known as Thermo-Plastic-Rubber, is a thermoplastic rubber material. It is based on thermoplastic styrene-butadiene rubber (SBS, SEBS) as the raw material, through the addition of resins (such as PP, PS), fillers, plasticizing oil and other functional additives mixed and modified.TPR material has the resilience of rubber and good abrasion resistance, non-slip, shock absorption properties, while having excellent processing performance and environmental protection.

Comparison of PVC and TPR materials

1. Raw material and composition

PVC is mainly composed of polyvinyl chloride, and its performance is improved by adding plasticizers and stabilizers. On the other hand, TPR is made of thermoplastic styrene-butadiene rubber as the basic raw material, which is blended and modified by adding many kinds of additives. From the raw material and composition, PVC and TPR have essential differences.

2. Physical properties

PVC has excellent corrosion resistance, heat resistance, flame retardant and mechanical properties. It can maintain stable performance at high temperatures and resist the erosion of acids, alkalis, salts and other chemicals.PVC also has good insulating properties and can be used as insulating materials for wires and cables.TPR material has the resilience of rubber and good abrasion resistance, anti-slip and shock absorption properties. It is softer and more comfortable than rubber, but the material tensile strength, fatigue resistance and mechanical properties are not as good as vulcanized rubber.

3. Processing performance

PVC material has good plasticity, can be made into a variety of shapes and sizes of products through thermal processing, injection molding, etc. PVC material is not easy to produce bubbles and defects in the process, has good processing performance. TPR material also has good processing performance, can be molded by injection molding, extrusion, blow molding and other processing methods, TPR material and some glue, ink, etc. have good bonding performance, easy to follow up processing and coating.

4. Environmental performance

PVC material is more environmentally friendly than other plastic materials. It has good recyclability and reusability, in line with environmental requirements. As PVC needs to add heat stabilizers during processing, these stabilizers may contain lead salts and other hazardous substances, so you need to pay attention to environmental issues in the use and recycling process. As an environmentally friendly soft rubber, the main hazardous substances such as plasticizers phthalates, nonylphenol NP, PAHs and other polycyclic aromatic hydrocarbons, etc. are in line with ROHS, REACH, EN71-3, ASTMF963 and other environmental testing standards, and have a high level of environmental performance.

5. Application areas

Due to the differences in the performance of PVC and TPR, they are also different in the field of application. PVC materials are widely used in chemical industry, environmental protection, wire and cable, automobile, construction and other fields. Rigid PVC can be made into transparent, semi-transparent and various colors of pearl products; soft PVC can be made into agricultural film, raincoats, tablecloths, curtains and so on. TPR materials are widely used in daily products, adult products, hardware tools, luggage wheels, sports equipment, etc. TPR materials can be used to make toys, shoe soles, tires and other products.

Fourth, the choice and application of PVC and TPR

In the selection of PVC and TPR materials, need to be based on specific application scenarios and needs for comprehensive consideration. If you need materials with excellent corrosion resistance, heat resistance, flame retardant and mechanical properties, as well as good insulation properties, then PVC is a good choice. If you need the material has the resilience of rubber and good abrasion resistance, anti-slip, shock absorption performance, as well as excellent processing performance and environmental performance, then TPR is a better choice.

In the application process, you also need to pay attention to the material processing temperature, pressure and other parameter settings, as well as subsequent processing and coating and other process requirements. In the use and recycling process need to pay attention to environmental issues, to ensure compliance with relevant environmental regulations and standards.

V. Conclusion

PVC and TPR are two distinctive plastic materials. They have obvious differences in raw materials, physical properties, processing performance, environmental performance and application areas. In the selection and application of these two materials need to be based on specific needs for comprehensive consideration to ensure that the performance and quality of products to meet the requirements.

TPR bearing wheels and PVC bearing wheels have their own advantages and disadvantages, the choice of which is better depends on the specific needs and use of the environment.

Performance Comparison

Abrasion resistance: TPR material itself has good abrasion resistance, while the abrasion resistance of PVC material is relatively poor.

Load-bearing capacity: TPR material is lighter in specific gravity, and its load-bearing capacity is generally inferior to that of PVC material.

Temperature adaptability: TPR materials perform better at high temperatures and can withstand higher temperatures, while PVC materials are easy to soften at high temperatures.

Environmental protection: PVC material has certain problems in environmental protection, while TPR material is relatively more environmentally friendly.

Application Scenario

TPR bearing wheel: suitable for the need for good wear resistance and high temperature adaptability of the occasion, such as the need for frequent use of the suitcase wheels.

PVC bearing wheel: suitable for some of the higher requirements for load bearing but the temperature change is not big occasions.

Price Comparison

TPR bearing wheel: relatively high price, but longer service life.

PVC bearing wheel: lower price, but shorter service life.

Environmental protection

TPR bearing wheel: relatively more environmentally friendly, in line with modern environmental requirements.

PVC bearing wheel: less environmentally friendly, especially in some regions or countries with strict environmental requirements may be restricted.

Related Keywords

Related Keywords