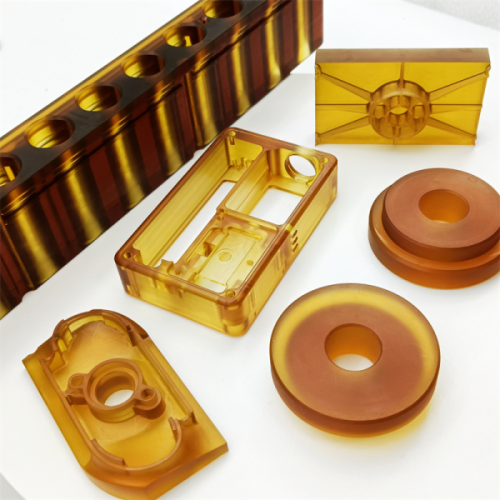

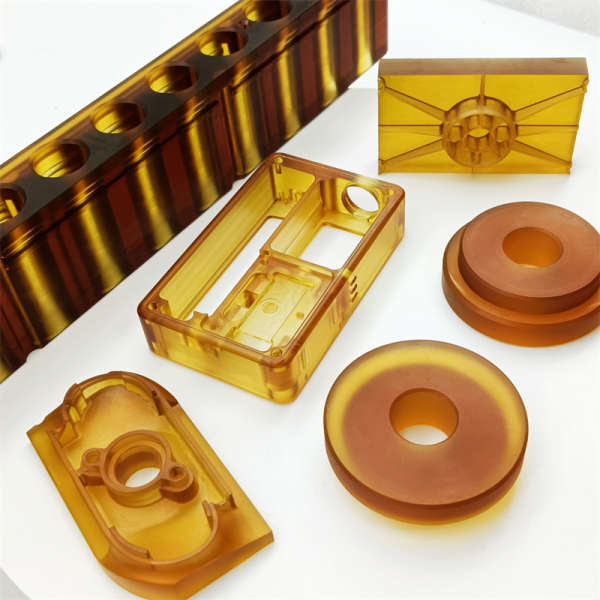

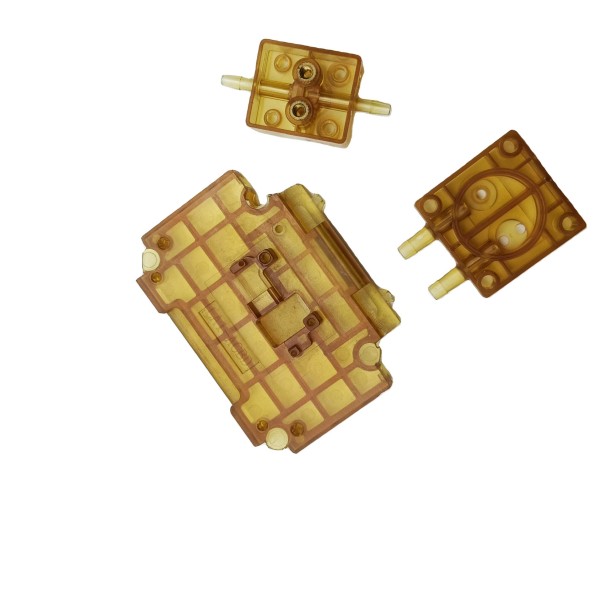

PPSU CNC lathe processing part

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 100 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

Processing performance of PPSU material

Abstract: PPSU material has excellent performance characteristics such as high temperature resistance, chemical resistance, etc. It shows good melt flow, thermal stability and chemical resistance during processing, and is capable of rapid mold filling and improved productivity. It is widely used in medical devices, electronic appliances, automotive industry and other fields. In the future, with the increasing concern for environmental protection and health, PPSU materials will be more widely used in the fields of medical devices, food packaging, etc. Meanwhile, under the expanding market of new energy vehicles, the application in the manufacture of automotive parts will be further developed.

In today's material science field, PPSU materials have attracted much attention due to their unique properties. As a class of high-performance thermoplastics, PPSU exhibits many excellent performance characteristics during processing. This paper will focus on the processing performance of PPSU materials, in order to provide a useful reference for the development of related industries.

I. Introduction of PPSU material

PPSU, known as polyphenylsulfone, is a thermoplastic made of alternating benzene rings and sulfur atoms. Due to its unique chemical structure, PPSU materials have excellent high temperature resistance, chemical resistance, low water absorption and other performance characteristics. These characteristics make PPSU materials have been widely used in many fields, such as medical equipment, electronic appliances, automotive industry and so on.

Processing properties of PPSU materials

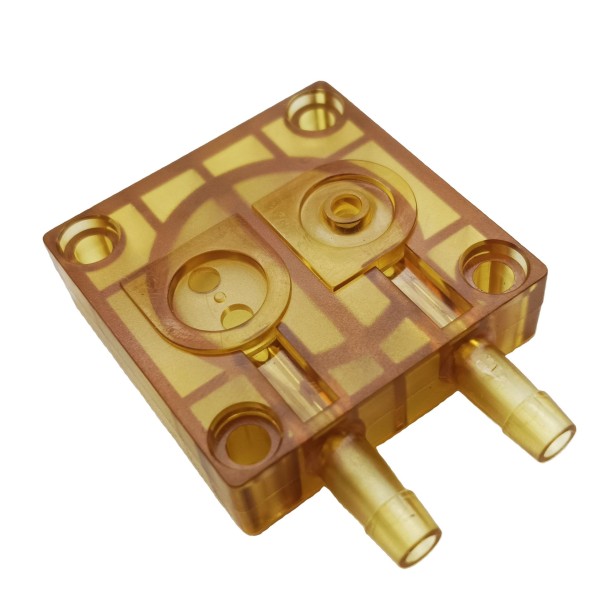

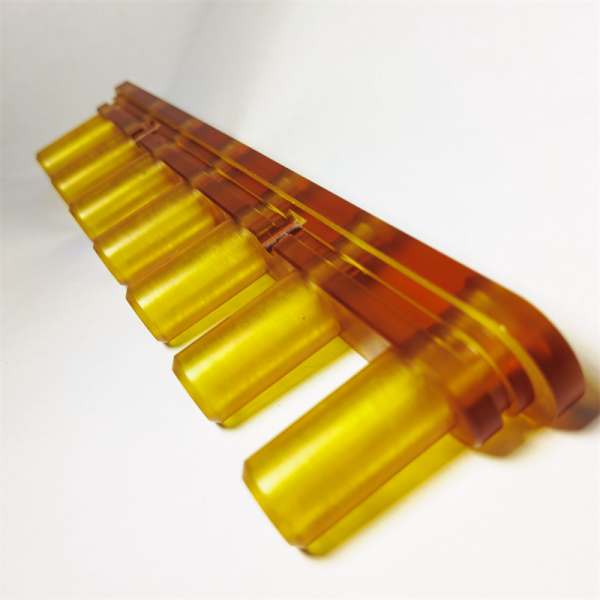

1. Melt flowability

PPSU material has good melt flowability, so that it can quickly fill the mold during processing, improve production efficiency. In addition, PPSU has a low melting point, can be processed at lower temperatures, reducing equipment wear and energy consumption.

2. Thermal stability

PPSU materials show good thermal stability at high temperatures, so that it is not easy to decompose or discoloration during processing. This provides a strong guarantee for the stability of the process and the reliability of product quality.

3. Chemical resistance

Due to the excellent chemical resistance of PPSU material, it is able to resist the erosion of various chemical reagents during processing, which ensures the smooth progress of the processing and product quality.

4. Mechanical properties

PPSU material has high strength and rigidity, can maintain a better form of stability during processing. This helps to minimize the deformation and warping phenomenon during processing and improve the geometric accuracy of the product.

5. Processing temperature and time

PPSU material processing temperature is generally between 250 ℃ ~ 350 ℃, processing time according to specific process requirements. In the process, the processing temperature and time should be reasonably selected to ensure that the material is fully molten and flow, while avoiding overheating or burning and other undesirable phenomena.

6 processing equipment and tools

As PPSU material has good corrosion resistance and wear resistance, commonly used processing equipment including injection molding machines, extruders, blow molding machines and so on. In the selection of processing equipment and tools, should be based on specific production requirements for a reasonable configuration to ensure the smooth progress of production.

Third, the application prospects of PPSU materials

With the continuous development of science and technology, the application of PPSU materials are also expanding. In the future, as people's concern for environmental protection and health continues to increase, PPSU materials as an environmentally friendly and non-toxic materials will be more widely used in medical equipment, food packaging and other fields. At the same time, with the new energy vehicle market continues to expand, the application of PPSU materials in the manufacture of automotive parts will also be further developed. In addition, PPSU materials in electronic and electrical appliances, aerospace and other fields of application prospects are also very broad.

In short, PPSU materials as a high-performance thermoplastics, its excellent processing performance for the development of related industries to provide strong support. In the future, with the continuous progress of technology and the continuous expansion of application areas, PPSU materials will play an important role in more areas. At the same time, we should also increase scientific research efforts to explore and optimize the potential performance of PPSU materials, and promote the sustainable development of related industries.

Specialty Engineering Plastics PPSU Processing - Food Processing Solutions

Polyphenylsulfone PPSU has long been a leader in solutions for wear parts for food processing machinery, and is also a solution for applications requiring food-grade and FDA-compliant plastics, from machined parts, to plastics processing for food processing technology to provide the latest in metal detectable and food-grade performance solutions.

PPSU is designed for food contact applications as an ultra detectable food grade plastic. Unlike other detectable plastics that can only be inspected by one or two methods, PPSU materials are suitable for all three standard inspection processes: X-ray, optical scanning and metal detection. PEEK materials are ideal for food and beverage processing components as well as components for conveyor belt technology where detection of hazardous particles is critical, and where easy-to-maintain materials are always a welcome addition to the food processing industry. In the food processing industry, easy-to-maintain material plants or factories are always welcome. The high chemical resistance of these cladding systems allows them to withstand long periods of operation and reduces the need for frequent hygienic maintenance. These materials also have excellent structural strength, rigidity and fire resistance to withstand the rigors of food processing and production.

As a versatile material that can be used in many industries, PPSUs are processed from ultra-high polymer materials into parts that can be used in virtually every aspect of the food production cycle, from rollers and guides in knife-grinding systems to wear strips for application butchery, the applications for specialty engineering plastics in the food processing industry are virtually endless, serving as a solution for power transmission processing and customized parts in food processing applications.

And with a full range of specification sizes and support for customization, specialty engineering plastics are particularly versatile, offering sheet and bar stock, custom pellets, and plastic alternatives to metal power transmission parts.

Related Keywords

Related Keywords