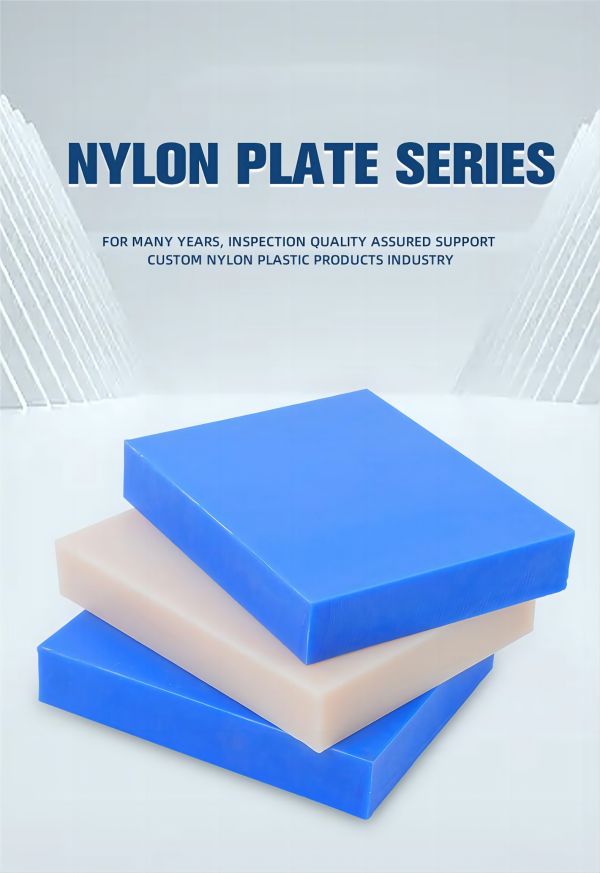

Nylon 6 Nylon 66 Nylon Sheets

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 100000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Nylon plate material includes molybdenum disulfide, using sodium metal, sodium hydroxide, etc. as the main catalyst, N-acetyl caprolactam as a co-catalyst, amine directly in the model through the negative ion ring-opening polymerization and produced. Nylon is the five engineering plastics in the application of the * wide variety, the material has * more comprehensive performance, including mechanical strength, stiffness, toughness, mechanical shock absorption and wear resistance.

What are the characteristics of nylon sheet?

Nylon plate is characterized by toughness, shock resistance, high mechanical strength and heat resistance, good impact strength, but also has the role of waterproofing, this feature is now vital in life, waterproof performance makes the quality of the building on the improvement, people do not have to worry about the occurrence of water leakage of the house.

Nylon plate surface is free of any other impurities, its toughness is good, applied in life, has the effect of shockproof; then it is very hard, more wear-resistant, with it to do mechanical parts is very durable.

The production of nylon plate when the temperature is high, so it also has the effect of high temperature; it is not easy to be corroded by chemicals, high corrosion resistance; at the same time can also reduce the noise, mechanical properties to improve productivity is also improved!

The application of nylon plate

1. Nylon plate has good toughness, abrasion resistance, oil resistance, shock resistance, tensile, bending strength, and has a small water absorption, good dimensional stability, etc. Nylon plate has good toughness, and thus is used to process a variety of wear-resistant high-strength parts.

2. Nylon plate is widely used, is a plastic instead of steel, iron, copper and other metals, a good material, is an important engineering plastics; cast nylon widely instead of mechanical equipment wear parts, instead of copper and alloy for equipment wear parts.

3. Nylon plate is suitable for making wear-resistant parts, transmission structure parts, household appliances parts, automobile manufacturing parts, screws to prevent mechanical parts, chemical machinery parts, chemical equipment. Such as turbines, gears, bearings, impellers, cranks, instrument panels, drive shafts, valves, blades, screws, high pressure washers, screws, nuts, seals, bobbins, sets of simple, bushing connectors.

Nylon plate and pp plate difference

(a) Difference in characteristics:

1. The main characteristics of nylon plate bar: its comprehensive performance is good, high strength, stiffness and hardness, creep resistance, wear-resistant, heat aging (using temperature range of 40 degrees ~ 120 degrees), good machine performance.

2.PP plate main characteristics: small specific gravity, non-toxic, insulation, resistance, alkali, corrosion, a variety of specifications can be customized.

(ii) Application areas:

1.Nylon plate applications: cast nylon widely used in place of wear parts of machinery and equipment, instead of copper and alloy for equipment wear parts. Such as bushings, shaft tiles, bushings, liner, teeth, worm roller copper guide, piston rings, seals, sliders, ball bowls, leaves, blades, cams, nuts, valve pieces, pipes, stuffing box, rack, belt, pump rotor and so on. Due to the simple structure of the process and mold, the cost is relatively low, become an ideal material to replace copper, stainless steel, aluminum alloy, PTFE, etc..

2. pp plate is widely used in acid and alkali equipment, electroplating equipment, solar photovoltaic equipment, environmental protection equipment, wastewater, waste gas discharge equipment, scrubber tower, clean room, semiconductor plants and related industrial equipment, but also the manufacture of plastic tanks of choice of materials, of which PP thick plate is widely used in stamping plates, press pads, etc.

Related Keywords