Nylatron® GSM PA6 Cast nylon with MoS₂ MCAM

-

$6.901-99 Kilogram

-

$6.80100-999 Kilogram

-

$6.70≥1000 Kilogram

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 100000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shenzhen,Guangzhou,Hongkong |

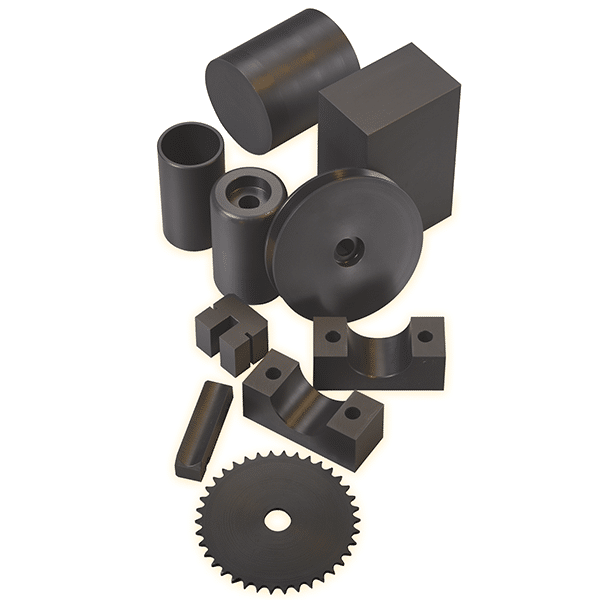

Nylatron® GSM Polyamide PA6 shapes contain finely divided particles of Molybdenum Disulphide (MoS₂) to enhance their load bearing capabilities while maintaining the impact resistance inherent to cast nylon products. This grade in particular possesses an ideal combination of strength and toughness, while also exhibiting excellent mechanical and electrical properties. This powerful combination of characteristics makes Nylatron® GSM PA6 an ideal material for use in gears, bearings, sprockets, and sheaves throughout the construction and heavy equipment markets.

Nylatron® GSM contains finely divided particles of molybdenum disulphide (MoS2) to enhance its load bearing capabilities while maintaining the impact resistance inherent to nylon. Nylatron® GSM is most commonly used grade for gears, sheaves, sprockets and custom parts. Nylatron® GSM is grey-black in color.

Nylatron® GS and GSM are filled nylons which have stiffer, harder and dimensionally more stable properties than unmodified nylons. The addition of MoS2 (molybdenum disulphide) creates a strong crystalline structure which enhances bearing and wear behaviour, without impairing the inherent impact and fatigue resistance of cast nylons.

Nylatron® GS and GSM are self-lubricating, quiet in operation and their lightness contributes to low inertia, which is often a factor under stop/start conditions. They are easily machined, have good load-bearing capabilities and their low co-efficient of friction makes them ideal for many bearing applications. MoS2-filled Nylatron® GS is also available in profile and strip form to provide an economic solution for heavy wear and load situations.

MC PA6G Temperature range:

Nylatron® GS: -20°C to +95°C (-20°C to +70°C in water)

Nylatron® GSM: -30°C to +105°C (-30°C to +70°C in water)

Nylon 6 Nylon 66 Key Properties

- Broadest size range availability

- Good mechanical and electrical properties

- Ideal balance of strength and toughness

- Cast as finished parts and near net shapes (nylon 6)

Pa6G Sheet Rod Limitations

- High Moisture Absorption

- Limited Resistance to Strong Acids & Alkalies Note - Nylons can absorb up to 7% (by weight) water under high humidity or submerged in water. This can result in dimensional changes up to 2% and a corresponding reduction of physical properties. Proper design techniques can frequently compensate for this factor.

Mc Nylon Plate Applications

- Bushings & Bearings

- Conveyor Wear Components

- Gears

- Metal Replacement Applications

- Pulleys

- Roller Wheels

- Sheaves

- Wear Pads

- Bearing & Wear Parts for a Wide Range Automated Equipment

- Valve Seats & Seals

Related Keywords